The development of safety footwear began in the early twentieth century as a direct response to the hazardous conditions created by rapid industrialization. Lacking any specialized protection, workers in factories, mines, and construction sites faced a constant threat of debilitating foot injuries from falling objects and heavy machinery.

The invention of safety footwear was not a single event but an essential evolution driven by the collision of new industrial dangers, emerging worker protections, and the technological capability to create a solution.

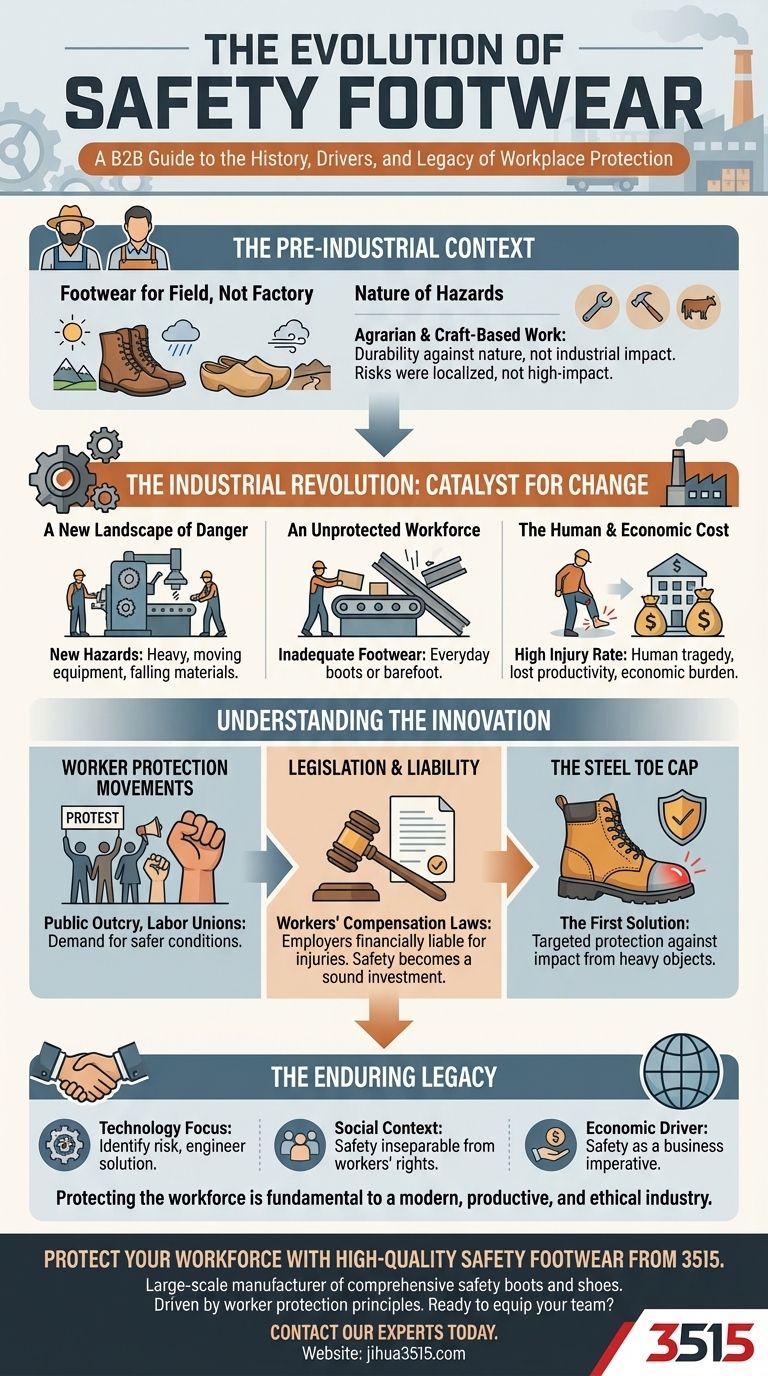

The Pre-Industrial Context: A Different Set of Risks

Footwear Designed for the Field, Not the Factory

Before the industrial era, most work was agrarian or craft-based. Footwear, typically made of leather or wood, was designed for durability against weather and terrain, not for industrial impact. The primary goal was to keep feet dry and protected from the natural environment.

The Nature of Pre-Industrial Hazards

While farming and manual crafts had their own dangers, they lacked the concentrated, high-impact risks found in factories. The threat was more likely to be a misplaced hand tool or a mishap with livestock, not a multi-ton piece of machinery or falling steel beam.

The Industrial Revolution: A Catalyst for Change

A New Landscape of Danger

The rise of factories, mines, and large-scale construction in the late 19th and early 20th centuries created entirely new types of workplace hazards. Workers were now surrounded by heavy, moving equipment and the constant risk of falling materials. This dramatically increased the frequency and severity of foot and leg injuries.

An Unprotected Workforce

Early industrial laborers often wore their inadequate everyday boots, or in some cases, worked barefoot. This left them completely vulnerable to crushing, piercing, and impact injuries that could end a career in an instant.

The Human and Economic Cost

The high rate of injury was a human tragedy, but it also created a significant economic problem for employers. An injured worker meant lost productivity, and as labor movements grew, the demand for safer working conditions became impossible to ignore.

Understanding the Forces Behind the Innovation

The Push for Worker Protection

The early twentieth century saw a major shift in social attitudes. The rise of labor unions and public outcry over horrific working conditions began to place pressure on industries and governments to take worker safety seriously.

The Role of Legislation

The introduction of early workers' compensation laws was a critical turning point. These regulations made companies financially liable for injuries sustained on the job. Suddenly, investing in protective equipment like safety boots became a sound financial decision, not just a moral one.

The First Technological Solution: The Steel Toe

The defining innovation was the integration of a steel toe cap into a work boot. This simple but brilliant solution provided a shield specifically designed to counter the most common industrial threat: impact from heavy falling objects. This marked the birth of modern safety footwear.

The Enduring Legacy of This Development

The creation of safety footwear was a foundational step in the broader history of occupational health and safety. The principles that drove its invention continue to shape how we protect workers today.

- If your primary focus is the technology: The core innovation was identifying a specific, high-frequency risk (impact) and engineering a targeted material solution (the steel toe).

- If your primary focus is the social context: The demand for safety gear was inseparable from the larger struggle for workers' rights and humane labor conditions.

- If your primary focus is the economic driver: Safety became a business imperative once legislation shifted the financial liability for injuries onto employers.

This early innovation established a critical precedent: that protecting the health of the workforce is a fundamental component of a modern, productive, and ethical industry.

Summary Table:

| Key Driver | Impact on Safety Footwear Development |

|---|---|

| Industrialization | Created new hazards like falling objects and heavy machinery, increasing severe foot injuries. |

| Worker Protection Movements | Growing public and union pressure demanded safer working conditions for laborers. |

| Workers' Compensation Laws | Made employers financially liable for injuries, turning safety gear into a sound investment. |

| Steel Toe Cap Invention | Provided the first targeted technological solution to protect against crushing impacts. |

Protect Your Workforce with High-Quality Safety Footwear from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, designed to meet the highest safety standards and driven by the same principles of worker protection that started this industry.

Ready to equip your team with durable, reliable safety footwear? Contact our experts today to discuss your needs and discover how we can support your business.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What does a yellow triangle symbol on safety footwear mean? A Guide to CSA Grade 2 Protection

- What does electrical hazard protection (EH) in safety footwear entail? Essential Safety for High-Risk Environments

- What is the role of scuffcaps in safety footwear? Extend Your Boot's Lifespan with Durable Protection

- What are the technical benefits of a stable shoe model design in high-intensity medical environments? Boost Safety

- What are the different heights available for security guard safety boots? Choose the Right Height for Maximum Protection

- What features do Chemical Resistant safety boots have? A Complete Guide to Industrial Footwear Protection

- Why must fire boots have a melt-resistant sole? Ensure Uncompromised Safety in Extreme Heat

- What are the technical advantages of using eTPU midsole materials? Elevate Safety Footwear with Energy Return Tech