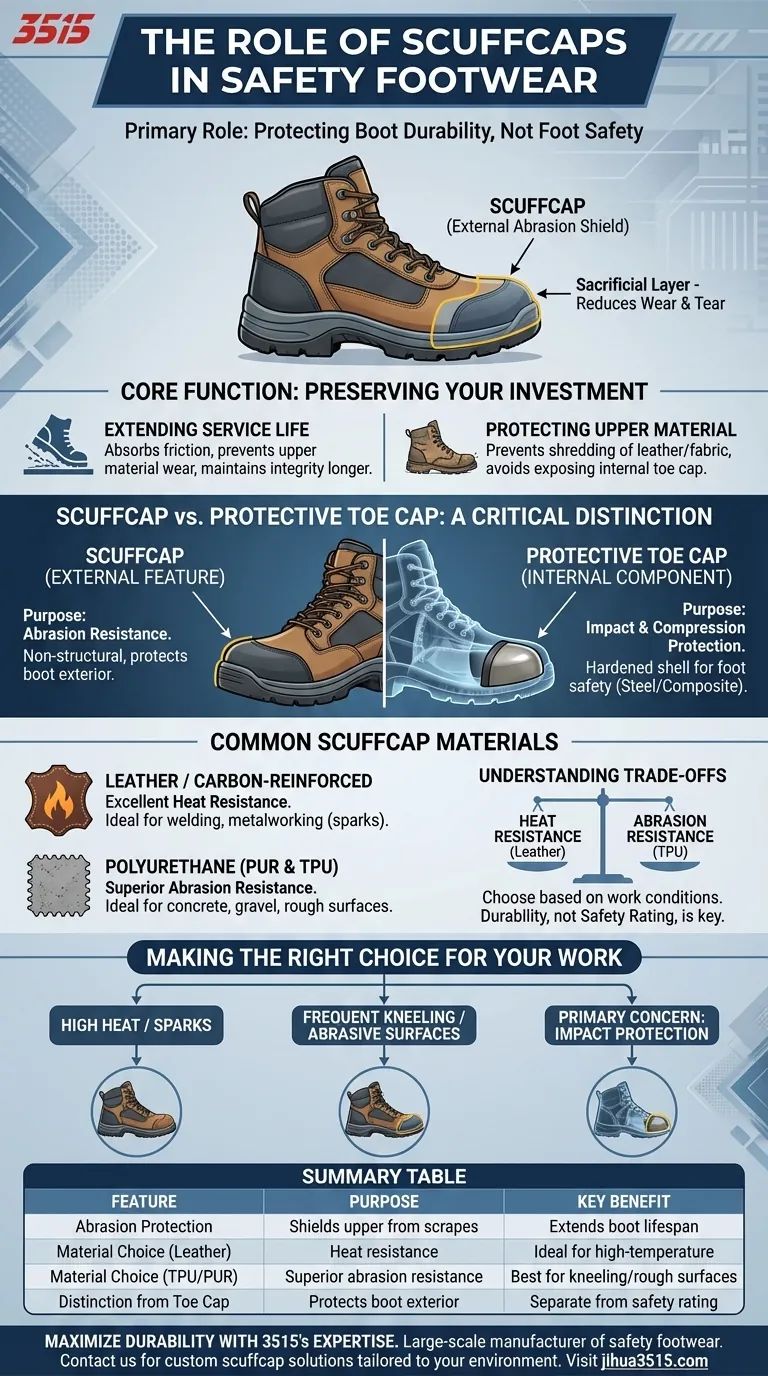

The primary role of a scuffcap is to protect the outer material of your safety footwear at the toe, drastically reducing wear and tear from abrasion. It acts as a sacrificial layer, shielding the boot's upper from scuffs, scrapes, and mechanical stress, which significantly extends the overall service life of the footwear.

A scuffcap is an external feature designed for boot durability, not direct foot protection. It protects the boot itself, while the internal safety toe cap (made of steel or composite) is the component that protects your toes from impact and compression.

The Core Function: Preserving Your Investment

A scuffcap's job is to take the abuse so the rest of your boot doesn't have to. For anyone whose work involves frequent kneeling, crawling, or working on abrasive surfaces, this feature is critical for preventing premature failure of the footwear.

Extending the Boot's Service Life

By absorbing friction and scrapes, the scuffcap prevents the underlying upper material, such as leather or synthetic fabric, from being worn through. This maintains the structural integrity and weather resistance of the boot for much longer.

Protecting the Upper Material

Without a scuffcap, the toe area is often the first part of a work boot to fail. Constant contact with rough surfaces can quickly shred the material, exposing the internal safety toe cap and compromising the boot's construction.

Scuffcap vs. Protective Toe Cap: A Critical Distinction

It is essential to understand that these are two different components with separate functions. The scuffcap is a non-structural piece of material added to the exterior of the toe for abrasion resistance.

The protective toe cap is a hardened, certified shell made of steel or composite material built inside the boot. This internal cap is what provides the mandatory protection against impact and compression hazards.

Common Scuffcap Materials

The material used for a scuffcap directly impacts its performance in different environments. The choice is a balance between abrasion resistance and heat resistance.

Leather and Carbon-Reinforced Leather

Traditional leather scuffcaps offer excellent resistance to heat, making them a suitable choice for environments like welding or metalworking where sparks or hot surfaces are common.

Polyurethane (PUR and TPU)

Foam Polyurethane (PUR) and Thermoplastic Polyurethane (TPU) are modern polymer materials. They are significantly more resistant to abrasion than leather, making them ideal for work on concrete, gravel, or other rough surfaces.

Understanding the Trade-offs

Choosing a boot with the right scuffcap—or one at all—depends entirely on your specific work conditions.

Abrasion vs. Heat Resistance

The primary trade-off is between materials. A TPU scuffcap will outlast leather against constant scraping and kneeling, but it can be damaged by high heat. Conversely, a leather scuffcap withstands heat better but will wear down faster from pure physical abrasion.

It's About Durability, Not Safety Rating

A boot without a scuffcap can have the exact same safety rating as one with it. The scuffcap does not contribute to the boot's ability to protect you from impact. Its absence simply means the toe area will wear out much faster, forcing you to replace your boots more frequently.

Making the Right Choice for Your Work

Evaluate your daily tasks to select footwear that will not only keep you safe but also provide the best long-term value.

- If your work involves high heat or sparks (e.g., welding): A boot with a leather scuffcap will provide the necessary heat resistance.

- If your work involves frequent kneeling or abrasive surfaces (e.g., construction, flooring, mechanics): A TPU or PUR scuffcap is superior and will dramatically extend the life of your boots.

- If your primary concern is impact protection: Focus on the boot's certified internal safety toe cap (steel or composite), as the external scuffcap plays no role in this critical safety function.

By understanding its role, you can choose footwear with a scuffcap that matches your job's demands, ensuring your investment lasts.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Abrasion Protection | Shields boot upper from scrapes and wear | Extends overall boot lifespan |

| Material Choice (Leather) | Heat resistance for welding/sparks | Ideal for high-temperature environments |

| Material Choice (TPU/PUR) | Superior abrasion resistance | Best for kneeling on concrete/rough surfaces |

| Distinction from Toe Cap | Protects boot exterior (not foot) | Maintains structural integrity; separate from safety rating |

Maximize the durability of your safety footwear with 3515's manufacturing expertise. As a large-scale manufacturer, we produce a comprehensive range of work boots and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities include boots with specialized scuffcaps tailored to your specific work environments—whether you need heat-resistant leather or ultra-durable TPU. Let us help you design or source footwear that offers lasting value. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors