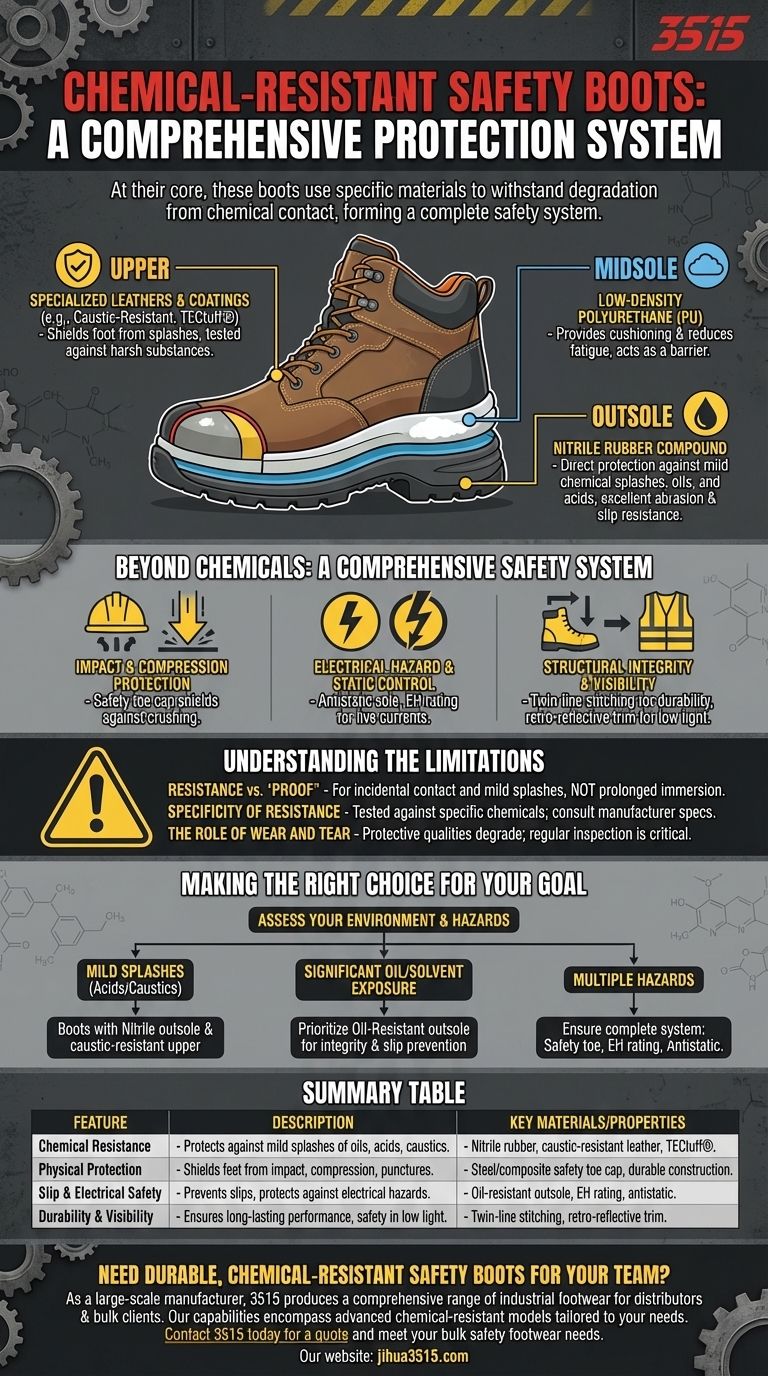

At their core, chemical-resistant safety boots are constructed from specific materials designed to withstand degradation from chemical contact. This typically involves a Polyurethane (PU) midsole for cushioning and a Nitrile rubber outsole for direct protection against mild chemical splashes, oils, and acids. Certain models also utilize advanced, specially treated uppers like caustic-resistant leather tested against harsh substances like Sodium Hydroxide and Sulphuric Acid.

The key is to understand that "chemical resistance" is not a single feature, but a comprehensive safety system. It combines specific chemical-blocking materials with a full suite of protections against impact, electrical, and slip hazards common in industrial environments.

The Foundation: Chemical-Resistant Materials

The choice of material is the most critical factor in a boot's ability to protect against chemical exposure. Each part of the boot's sole and upper plays a distinct role.

The Outsole: Your First Line of Defense

The outsole makes direct contact with the ground and any spills. A Nitrile rubber compound is the standard for chemical resistance because it effectively resists damage from oil, acids, and other common industrial chemicals without degrading.

This material is also chosen for its excellent abrasion and slip resistance, especially on oily surfaces.

The Midsole: Stability and Cushioning

A low-density Polyurethane (PU) midsole is often bonded to the outsole. While its primary role is to provide cushioning and reduce worker fatigue, its material properties also contribute to the boot's overall barrier against chemical intrusion.

The Upper: Specialized Leathers and Coatings

The boot's upper section relies on specialized materials to shield the foot from splashes. Advanced options include caustic-resistant leather or materials like TECtuff®, which are specifically treated and tested to resist penetration from substances like Sodium Hydroxide and Sulphuric Acid.

Beyond Chemicals: A Comprehensive Safety System

True chemical safety footwear integrates resistance with protection against other common workplace dangers. These features work together to create a complete safety solution.

Impact and Compression Protection

A compression-resistant safety toe cap is a non-negotiable feature. It protects the toes from being crushed by falling objects or heavy equipment, a constant risk in industrial settings.

Electrical Hazard and Static Control

Many chemical-resistant boots feature an antistatic sole complex. This is critical for environments where a buildup of static electricity could ignite flammable materials.

These boots also often carry an electrical hazard (EH) rating, providing underfoot protection from live electrical currents.

Structural Integrity and Visibility

Durability is paramount for safety. Features like twin-line stitching add significant strength to the boot's construction, preventing seams from failing after exposure to harsh substances.

For added safety in low-light conditions, retro-reflective trim is often included to enhance worker visibility.

Understanding the Limitations

Objectively assessing the limitations of your equipment is crucial for safety. "Resistant" does not mean "proof," and understanding the difference is key.

Resistance vs. "Proof"

Chemical-resistant boots are designed to protect against incidental contact and mild splashes. They are not intended for full, prolonged immersion in chemicals. Always match the level of protection to the specific risk of exposure.

Specificity of Resistance

A boot's resistance is tested against specific chemicals. A boot rated for Sulphuric Acid may not offer the same level of protection against a different type of solvent. Always consult the manufacturer's specifications for the specific chemicals it is rated to resist.

The Role of Wear and Tear

The protective qualities of any safety boot will degrade over time, especially with repeated chemical exposure and physical abrasion. Regular inspection for cracks, punctures, or material degradation is a critical safety practice.

Making the Right Choice for Your Goal

Selecting the correct boot requires a clear understanding of your specific work environment and its unique hazards.

- If your primary focus is protection from mild splashes of common acids and caustics: Look for boots with a Nitril rubber outsole and specifically designated caustic-resistant leather uppers.

- If your work involves significant oil or solvent exposure: Prioritize a boot with an oil-resistant outsole compound to maintain structural integrity and prevent slips.

- If you work in an environment with multiple hazards: Ensure the boot is a complete safety system with a safety toe cap, an electrical hazard (EH) rating, and antistatic properties.

Ultimately, choosing the right boot is about conducting a thorough risk assessment of your specific tasks and environment.

Summary Table:

| Feature | Description | Key Materials/Properties |

|---|---|---|

| Chemical Resistance | Protects against mild splashes of oils, acids, and caustics. | Nitrile rubber outsole, caustic-resistant leather, TECtuff® uppers. |

| Physical Protection | Shields feet from impact, compression, and punctures. | Steel or composite safety toe cap, durable construction. |

| Slip & Electrical Safety | Prevents slips on oily surfaces and protects against electrical hazards. | Oil-resistant outsole, EH rating, antistatic properties. |

| Durability & Visibility | Ensures long-lasting performance and safety in low-light conditions. | Twin-line stitching, retro-reflective trim. |

Need Durable, Chemical-Resistant Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including advanced chemical-resistant models tailored to your specific workplace hazards.

We provide high-quality, reliable footwear that combines chemical protection with impact resistance, slip resistance, and electrical hazard safety. Let us help you equip your workforce with the right protection.

Contact 3515 today for a quote and discover how our manufacturing expertise can meet your bulk safety footwear needs.

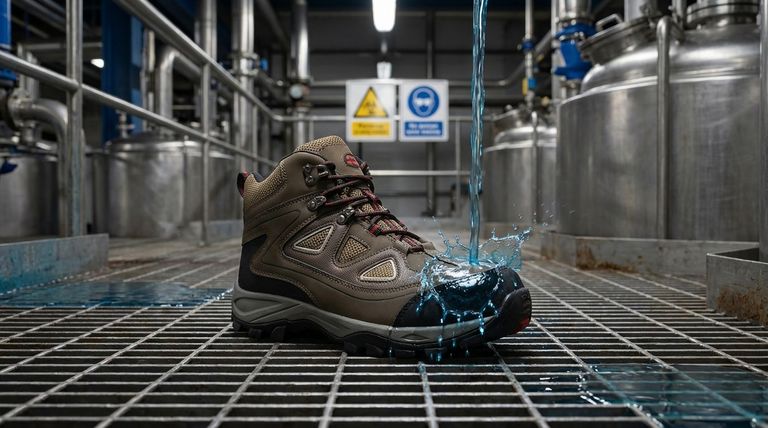

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What should customers consider when choosing safety footwear? A Guide to Perfect Fit & Protection

- How does the integration of embedded sensors in safety shoes contribute to long-term biomechanical monitoring?

- What role do industrial safety shoes play in feed production? Protect Your Workforce from Mechanical Hazards

- What types of toe protection are available in safety Wellington boots? Steel vs. Composite Toe Caps

- What role do Safety Shoes play in hospital environments? Essential PPE for Healthcare Staff Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why is protective footwear necessary in the manufacturing industry? Essential for Worker Safety and Compliance

- What is the recommended method for cleaning textile or synthetic work shoes? A Gentle Guide to Preserve Your Footwear