The definitive standard for metatarsal protection is a specific performance requirement set by ASTM International. Footwear meeting this standard must withstand a 75 foot-pound impact on the top of the foot while ensuring a minimum of one inch of clearance is maintained between the foot and the inside of the boot. Compliant boots are clearly identified with the "Mt" marking on their safety label.

The core principle of the ASTM metatarsal standard isn't just about resisting force, but about preventing the protective guard itself from crushing the delicate bones of the foot upon impact.

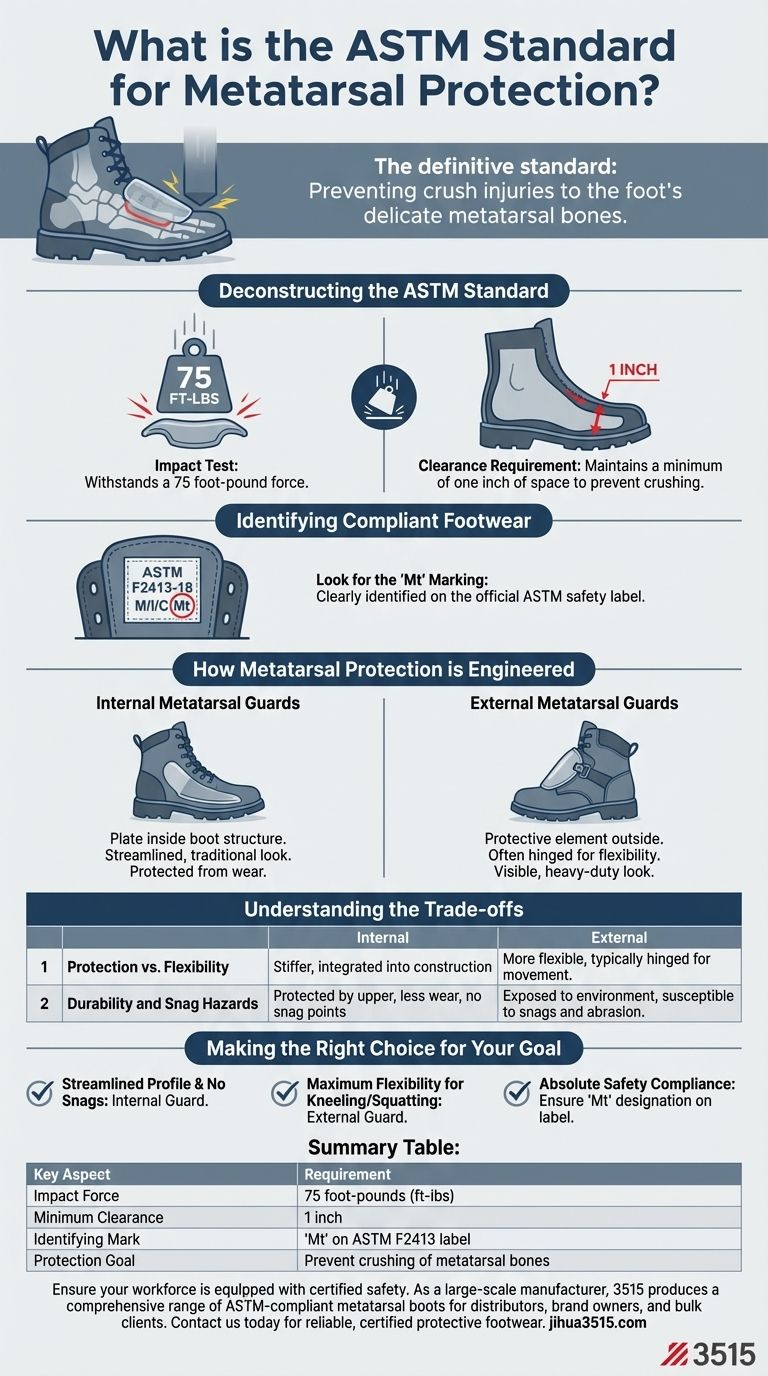

Deconstructing the ASTM Standard

To truly understand this rating, it's essential to break down its two key performance metrics. This isn't an arbitrary rule; it's a carefully engineered test designed to simulate real-world workplace hazards.

The Impact Test: 75 Foot-Pounds of Force

The standard mandates a controlled impact test where a weight is dropped onto the metatarsal guard. This impact must generate 75 foot-pounds (ft-lbs) of force.

This is a significant impact, designed to replicate scenarios like a heavy tool, pipe, or piece of material falling from a height directly onto the top of your foot.

The Clearance Requirement: A Critical Inch

Simply withstanding the impact is not enough. The most critical part of the test is what happens inside the boot.

During the 75 ft-lb impact, the boot must maintain at least one inch of clearance for the foot. A clay form is placed inside the boot during testing to measure this.

This ensures that even if the guard deforms slightly under impact, it will not collapse and crush the fragile metatarsal bones it is designed to protect.

Identifying Compliant Footwear: The 'Mt' Label

The only way to be certain your footwear meets this standard is to check the official ASTM label, which is typically sewn inside the boot tongue.

If a boot meets the metatarsal protection requirement, it will be clearly marked with 'Mt'. For example, a label might read "ASTM F2413-18 M/I/C Mt".

How Metatarsal Protection is Engineered

Manufacturers achieve this protection through two primary design philosophies, each with its own characteristics.

Internal Metatarsal Guards

This design places a protective plate, often made of rigid composite materials or steel, inside the boot's structure.

The guard sits on top of your foot but underneath the boot's exterior leather or fabric. This results in a more streamlined, traditional boot appearance.

External Metatarsal Guards

In this design, the protective element is attached to the outside of the boot, typically covering the laces and the top of the foot.

These external "shields" are often hinged to allow for greater flexibility when walking or bending. They are visibly apparent and can give the boot a more heavy-duty look.

Understanding the Trade-offs

Choosing between an internal and external guard involves more than aesthetics. Each design presents a different balance of flexibility, durability, and convenience.

Protection vs. Flexibility

External guards are often perceived as more flexible, as they are typically hinged and sit outside the boot's main structure, allowing for easier movement when squatting or climbing.

Internal guards, being part of the boot's construction, can sometimes create a feeling of stiffness across the top of the foot, though modern designs have improved this significantly.

Durability and Snag Hazards

An internal guard is completely protected by the boot's upper, shielding it from abrasions, chemicals, and wear.

An external guard is exposed to the work environment. This makes it more susceptible to getting caught on equipment, ladders, or debris, and it may wear down faster from direct contact.

Making the Right Choice for Your Goal

Your work environment and daily tasks should dictate the best design for your needs. Always prioritize the certified protection over the style.

- If your primary focus is a streamlined profile to avoid snagging: An internal metatarsal guard is the superior choice, as it offers protection with no external parts.

- If your primary focus is maximum flexibility for frequent squatting or kneeling: Consider boots with a well-designed external metatarsal guard, which can offer a better range of motion.

- If your primary focus is absolute safety compliance: Regardless of the design, confirm the boot has the 'Mt' designation on its official ASTM F2413 tag.

Ultimately, the best metatarsal boot is one that meets the standard while providing the comfort and mobility your specific job demands.

Summary Table:

| Key Aspect | Requirement |

|---|---|

| Impact Force | 75 foot-pounds (ft-lbs) |

| Minimum Clearance | 1 inch |

| Identifying Mark | 'Mt' on the ASTM F2413 label |

| Protection Goal | Prevent crushing of the metatarsal bones |

Ensure your workforce is equipped with certified safety. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant metatarsal boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of internal and external guard designs to meet your specific safety and flexibility needs.

Contact us today to discuss your requirements and get a quote for reliable, certified protective footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What steps can be taken if suitable footwear for all dangers is not available? Build a Safer Workplace Beyond the Boot

- Where should oil resistant safety boots be used? Essential Protection for Oily, Hazardous Workplaces

- What safety benefits do safety shoes with electrical insulation provide? Expert Protection for Sewing Operations

- How does the selection of materials for fall-prevention footwear influence performance? Elevate Safety with Science

- What are the properties of polyurethane (PU) outsoles in safety shoes? Discover the Perfect Blend of Lightweight Protection and Comfort

- What are the changes to puncture resistance in the new EN ISO 20345 standard? Understand P, PL, and PS Markings

- Which sole material has excellent performance in oil resistance? Find the Best Fit for Your Industry

- Why is toe room important in work shoes? Ensure All-Day Comfort and Prevent Injury