Selecting the right safety footwear requires a systematic evaluation of specific workplace hazards, compliance certifications, and material properties. You must match the protective features—such as impact resistance, electrical hazard protection, or slip resistance—directly to the environmental risks while ensuring the fit promotes long-term wearability.

Effective safety footwear selection is not about buying the most expensive boot; it is about precise alignment between environmental hazards and protective specifications. Prioritize verifiable certification and specific hazard ratings over general durability to ensure true compliance and safety.

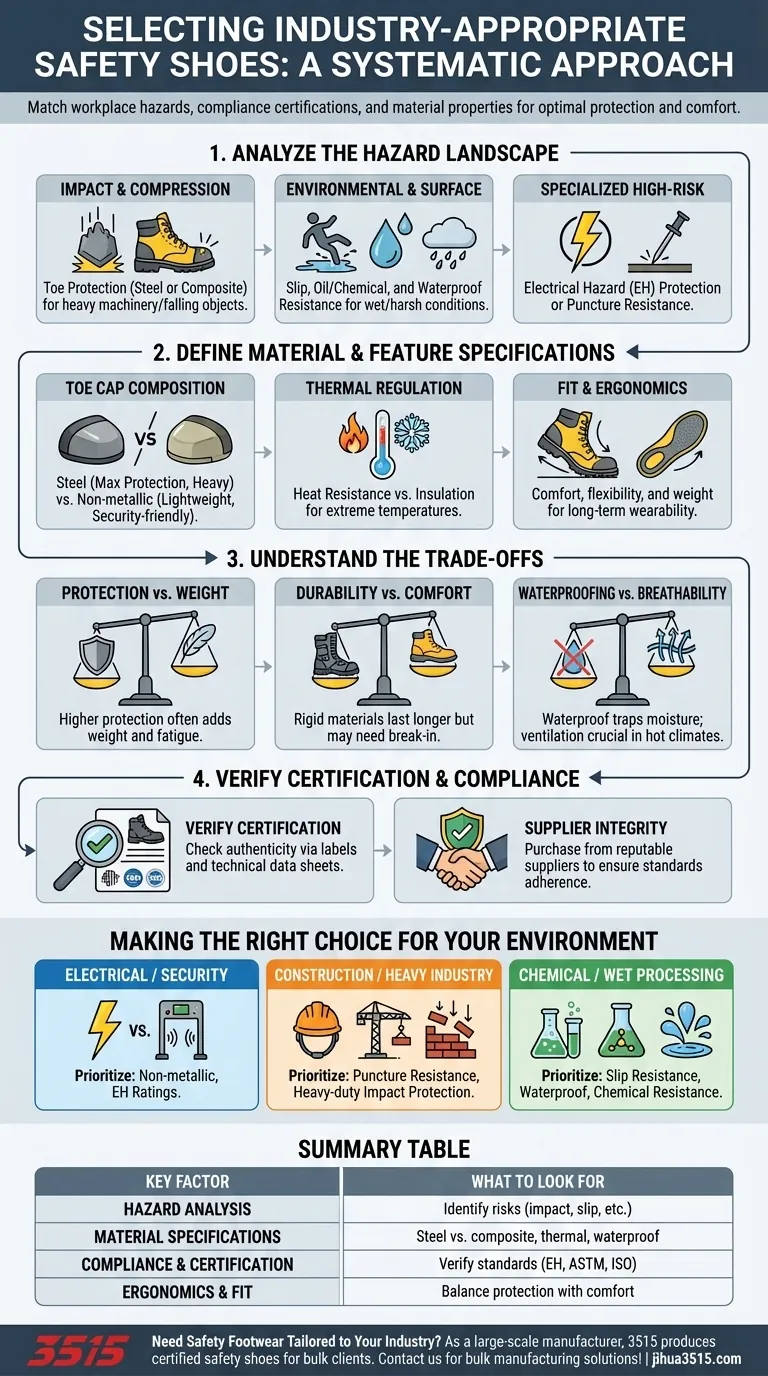

Analyzing the Hazard Landscape

The first step in selection is not choosing a shoe, but auditing the environment. You must identify the specific risks present in the workspace to determine the necessary protective classification.

Impact and Compression Risks

If the environment involves heavy machinery, moving parts, or the potential for falling objects, toe protection is non-negotiable. You must evaluate the weight and force of potential impacts to determine if standard protection is sufficient or if heavy-duty specifications are required.

Environmental and Surface Hazards

Slips, trips, and falls remain a leading cause of industrial injury. For wet or smooth surfaces, prioritize Slip Resistance; for industrial sites with harsh fluids, look for Oil/Chemical Resistance. If the job involves outdoor exposure or wet conditions, Water/Waterproof Resistance is essential to maintain foot health.

Specialized High-Risk Scenarios

Specific roles require specialized defenses that standard boots do not offer. Electricians require Electrical Hazard (EH) Protection to insulate against shocks. Conversely, environments with sharp debris, such as construction sites, demand Puncture Resistance in the sole.

Material and Feature Specifications

Once hazards are mapped, you must evaluate the technical construction of the footwear. The materials used determine both protection levels and daily usability.

Toe Cap Composition

The material of the protective toe cap affects weight and utility. Steel toes offer maximum protection but are heavier. Non-metallic options (composite) are lighter and essential for security environments requiring metal detector compatibility.

Thermal Regulation

Consider the temperature extremes of the workspace. Heat Resistance is vital for high-temperature jobs to prevent sole disintegration. Conversely, proper insulation is required for cold environments, though this often impacts breathability.

Fit and Ergonomics

A boot that protects the foot but causes fatigue leads to non-compliance. You must consider fit and style to ensure the footwear is comfortable enough for long shifts. Researching the weight and flexibility of the materials contributes to finding a durable, comfortable pair.

Understanding the Trade-offs

No single safety shoe is perfect for every situation. Understanding the inherent compromises in footwear design is critical for making an informed decision.

Protection vs. Weight

Higher levels of physical protection, particularly steel toes and metatarsal guards, inevitably add weight. This can lead to increased worker fatigue over long shifts. You must balance the severity of the risk against the mobility needs of the worker.

Durability vs. Comfort

Rigid, heavy-duty materials offer excellent longevity and protection but can be uncomfortable during the break-in period. Softer, lighter materials improve immediate comfort but may degrade faster in harsh chemical or abrasive environments.

Waterproofing vs. Breathability

Waterproof boots keep moisture out but also trap sweat inside. In hot environments, a fully waterproof boot may cause foot health issues due to moisture buildup. Ventilation is often a necessary trade-off against water resistance in hot, dry climates.

Verification and Compliance

Selecting the right features is useless if the product fails to meet safety standards.

Verifying Certification

Never rely solely on marketing claims. You must verify certification authenticity by inspecting the labels on the footwear. Cross-reference these with the manufacturer's technical data sheets to ensure they meet the specific safety regulations of your industry.

Supplier Integrity

Purchase only from reputable suppliers. Established vendors are more likely to carry stock that strictly adheres to current safety standards, reducing the liability risk associated with counterfeit or non-compliant gear.

Making the Right Choice for Your Environment

To select the industry-appropriate shoe, you must filter your choices based on your primary operational goal.

- If your primary focus is Electrical Work or Security: Prioritize Non-metallic construction and Electrical Hazard (EH) ratings to ensure insulation and metal-detector compatibility.

- If your primary focus is Construction or Heavy Industry: Prioritize Puncture Resistance and heavy-duty Impact protection to guard against sharp debris and falling objects.

- If your primary focus is Chemical or Wet Processing: Prioritize Slip Resistance, Waterproof materials, and Chemical resistance to prevent falls and material degradation.

By rigorously matching technical specifications to your specific environmental hazards, you ensure safety compliance and long-term worker well-being.

Summary Table:

| Key Selection Factor | What to Look For |

|---|---|

| Hazard Analysis | Identify impact, slip, electrical, or puncture risks. |

| Material Specifications | Steel vs. composite toes, heat/cold resistance, waterproofing. |

| Compliance & Certification | Verify EH, ASTM, or ISO standards via technical data sheets. |

| Ergonomics & Fit | Balance protection with comfort for long-term wearability. |

Need Safety Footwear Tailored to Your Industry?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear—from electrical hazard-resistant designs to heavy-duty puncture-proof boots—ensuring your workforce is equipped with gear that matches your specific environmental risks.

Let us help you enhance workplace safety and compliance. Contact us today for a consultation on our bulk manufacturing solutions!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety