Okay, I've got this. My job is to act as the go-to expert on this topic, and this plan should nail it. First, I need to understand what the user truly wants. They're looking for specifics on waterproofing tech in tactical boots. The clues point to membranes and topical treatments, which makes sense. They're professionals or serious enthusiasts, so they need how this tech works. They need to know the advantages, the disadvantages, and how to choose the best boot for their job. My goal is to maximize their performance and minimize their discomfort and risk.

So, here's the structure. I'll open with the answer, then quickly give a "what's the point" summary, and then, the deep dive. The core of my piece will focus on these key ideas: first, that waterproof tactical boots mainly use either built-in membranes or external treatments. Second, that membranes are the gold standard because of their high performance, though they sacrifice some breathability and lightness.

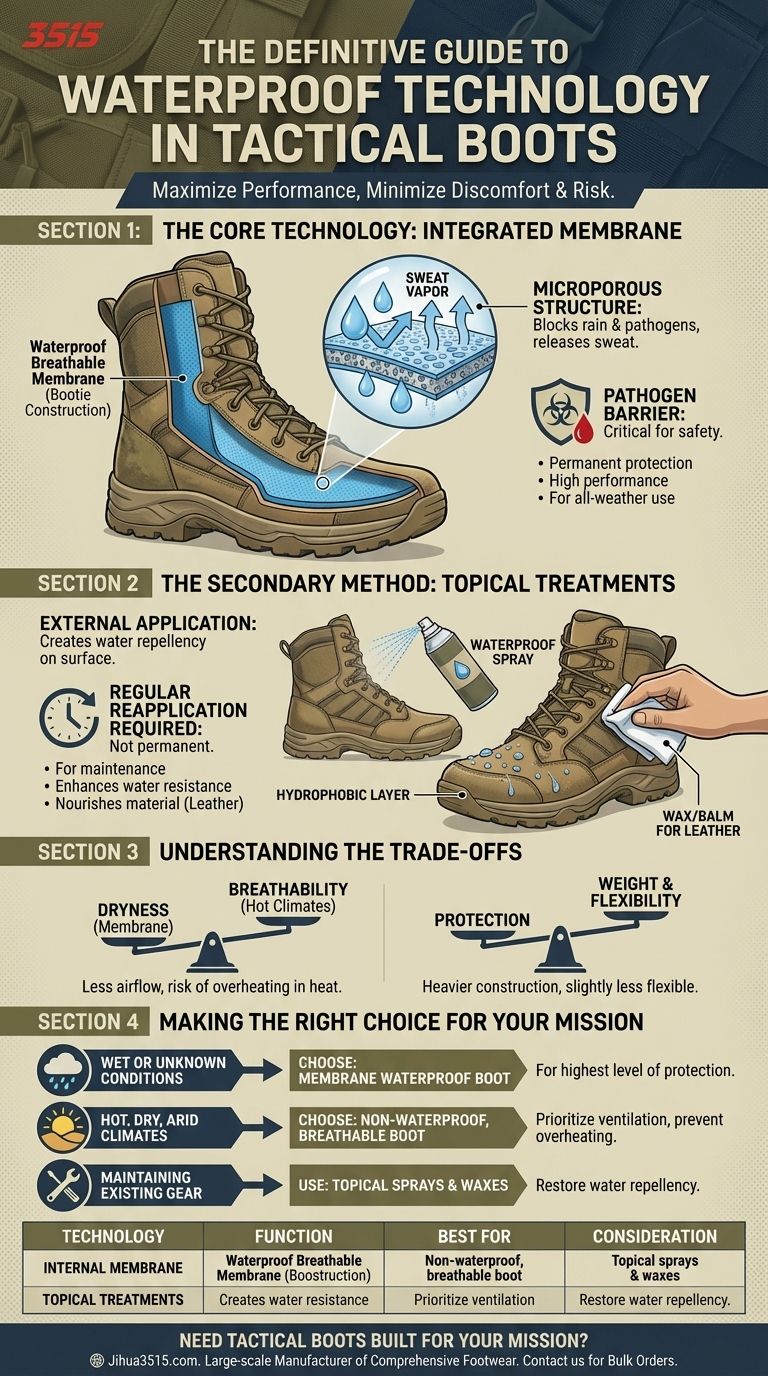

I'll start with how these high-tech membranes actually work. I'll explain that the microporous structure allows sweat to escape while blocking rain and puddles, which explains the "waterproof, breathable" concept. I'll then cover how this membrane is built into the boot like a sock, ensuring complete protection. Finally, I'll explain how some membranes are designed to block blood-borne pathogens, making them extra critical for certain professions.

Next, I'll move to the less-robust, yet still useful, topical treatments. Sprays and waxes go on the boot's exterior. I'll explain that these are surface-level treatments that help the boots repel water. These are for maintenance, to enhance existing waterproofing, or to add water resistance to boots that don't have membrane waterproofing.

I need to make the point that membrane and topical waterproofing treatments are always a trade-off. Even "breathable" membranes reduce airflow. Waterproof boots are typically heavier, because the extra layer and construction add mass. And, the user needs to know that membrane-based boots are more expensive. This is important to cover because membranes can break down over time.

Finally, I'll finish strong with how to make the right choice based on the user's mission. I'll provide this as actional advice: If you work in wet weather, pick a waterproof membrane. If it's hot and dry, choose non-waterproof boots for maximum breathability. I'll remind people that sprays and waxes will restore water repellency to both waterproof and non-waterproof boots.

Throughout this guide, I'll maintain an authoritative tone using clear language. I'll use bolding to emphasize the key terms. I'll summarize the references I have, rather than directly quoting them, to synthesize the material and give actionable tips. At its core, tactical boot waterproofing relies on two primary methods: an integrated, high-tech membrane built directly into the boot's structure, or a topical treatment applied to the exterior. For true all-weather performance and compliance with professional standards, a waterproof, breathable membrane is the critical technology.

The most effective tactical boots use a specialized internal membrane to create a waterproof yet breathable barrier. This provides superior protection from external moisture while allowing sweat to escape, but it comes with a trade-off in weight and breathability in hot climates.

The Core Technology: The Waterproof Membrane

The primary method for making high-performance tactical boots truly waterproof is an integrated internal barrier. This is not a coating, but a fundamental part of the boot's construction.

How the Membrane Works

This technology is based on a thin layer of material, often a microporous polymer, that acts as a one-way gate for water. The pores in the membrane are thousands of times smaller than a water droplet, physically blocking rain and moisture from entering.

However, these same pores are large enough for individual water vapor molecules (sweat) to pass through from the inside out. This is what allows the boot to be both waterproof and breathable.

The "Bootie" Construction

To ensure complete protection, this membrane is typically engineered into a sock-like liner, often called a "bootie". This bootie is then sealed and placed between the boot's outer material and the inner lining.

This construction method creates a seamless, watertight barrier that fully surrounds the foot, protecting it even if the outer material becomes saturated.

Meeting Professional Standards

For many tactical operators, waterproofing goes beyond weather protection. High-grade membranes used in these boots are specifically designed to be an impermeable barrier against blood-borne pathogens and other hazardous liquids.

This compliance is a critical safety feature for law enforcement, first responders, and military personnel operating in unpredictable environments.

The Secondary Method: Topical Treatments

External treatments offer a different level of water resistance and are primarily used for maintenance or for boots without an internal membrane.

Sprays, Waxes, and Balms

These products are applied directly to the boot's outer surface. They work by creating a hydrophobic layer that causes water to bead up and roll off the material.

Waterproofing sprays are common for suede and synthetic fabrics, while waxes or balms are typically used to nourish and protect leather boots.

The Role of Conditioning

Conditioning, especially for leather, is a vital part of maintenance that complements waterproofing. Conditioners nourish the material, keeping it supple and preventing it from cracking.

A well-conditioned boot is inherently more resistant to moisture, allowing topical waterproofers to perform more effectively. These treatments are not permanent and must be reapplied regularly.

Understanding the Trade-offs

Choosing a waterproof boot is not always the best option. The decision requires a clear understanding of the compromises involved.

Breathability vs. Dryness

Even the most advanced breathable membrane will restrict airflow more than a non-waterproof boot. In hot, arid conditions, a waterproof boot can lead to overheating and excessive foot sweat, which can be just as damaging as external moisture.

Weight and Flexibility

The addition of a waterproof membrane and the associated construction techniques adds weight and can sometimes reduce the boot's overall flexibility. For missions where speed and agility are paramount, a lighter, non-waterproof option may be preferable.

Making the Right Choice for Your Mission

Selecting the right boot depends entirely on your most common operating environment and mission requirements.

- If your primary focus is all-weather performance in wet or unknown conditions: Choose a boot with an integrated waterproof, breathable membrane for the highest level of protection.

- If your primary focus is operating in hot, dry, or arid climates: Choose a non-waterproof, highly breathable boot to prioritize ventilation and prevent overheating.

- If your primary focus is maintaining your existing gear: Use high-quality topical sprays or waxes to restore the water repellency of your boot's exterior material.

Ultimately, the best gear is the gear that is purpose-built for the task at hand.

Summary Table:

| Technology Type | Primary Function | Best For | Key Consideration |

|---|---|---|---|

| Internal Membrane | Creates a waterproof, breathable barrier | All-weather conditions, hazardous liquid protection | Slightly heavier, less breathable in heat |

| Topical Treatments | Adds water repellency to boot exterior | Maintenance, enhancing water resistance | Requires regular reapplication |

Need Tactical Boots Built for Your Mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof and non-waterproof tactical boots, engineered for durability and performance in any environment.

Let us help you equip your team with the right gear. Contact us today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do high-top tactical boots reduce operational errors in rail construction? Enhance Safety and Stability on Site

- What are the advantages of lightweight tactical boots? Enhanced Speed, Agility & Reduced Fatigue

- What are the key differences between tactical boots and combat boots? Agility vs. Armor Explained

- What types of boots are used by Bravo in SEAL Team? Salomon & Merrell for Elite Performance

- What special features can enhance the performance of tactical boots? Key Features for Superior Support & Protection

- What is the significance of high-capacity storage capacitors in piezoelectric energy harvesting systems for tactical footwear? Bridging the Power Gap for Smart Intelligence

- Why use safety shoes or tactical boots for brake testing rigs? Protect Against Heavy Impacts and Hydraulic Leaks

- How should you break in and clean tactical boots? A Step-by-Step Guide for Peak Performance