At their core, composite toe work boots provide robust protection against impact and compression injuries, just like traditional steel toe caps. However, their primary advantage lies in their non-metallic construction, which offers superior electrical hazard resistance and makes them significantly lighter and suitable for environments with metal detectors.

The essential function of a composite toe boot is to protect your feet from crushing forces and electrical shock. Its true value, however, comes from its lightweight, non-metallic properties, which provide comfort and convenience that steel cannot match in certain work environments.

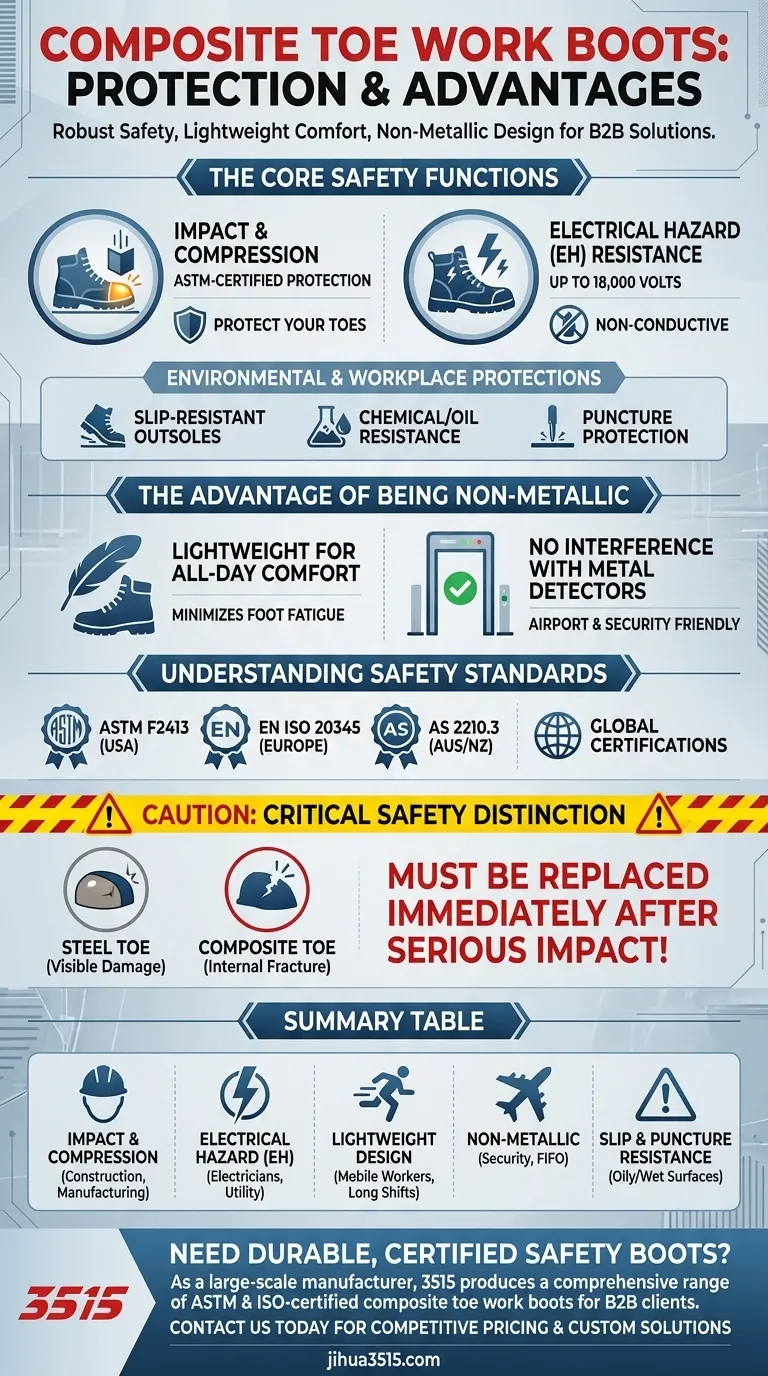

The Core Safety Functions

A work boot's primary job is to prevent injury. Composite toe boots achieve this through a combination of modern materials and design that meets rigorous safety standards.

Protection from Impact and Compression

The most critical feature is the composite toe cap itself. It's designed to protect your toes from being crushed by falling objects or compressed by heavy machinery, a common hazard in manufacturing and construction.

These boots are ASTM-certified, meaning they have been tested to withstand specific levels of impact and compression, ensuring reliable protection.

Electrical Hazard (EH) Resistance

Because composite materials are non-conductive, these boots offer excellent protection against electrical shocks. This is a critical advantage over steel toes.

Many models meet ASTM F2413 EH standards, rated to protect against open circuits of up to 18,000 volts in dry conditions.

Environmental and Workplace Protections

Beyond the toe cap, these boots are built to handle diverse conditions. They frequently feature slip-resistant rubber outsoles with deep lugs for superior traction on oily or wet surfaces.

The materials used often provide resistance to chemicals and oils, while some designs also incorporate plates to protect against punctures from below.

The Advantage of Being Non-Metallic

The use of composite materials—like Kevlar, carbon fiber, and fiberglass—provides unique benefits that extend beyond basic safety.

Lightweight for All-Day Comfort

Composite toe boots are noticeably lighter than steel toe boots. This reduction in weight minimizes foot fatigue, a significant benefit for mobile workers or anyone who spends long hours on their feet.

No Interference with Metal Detectors

Their non-metallic construction means you can pass through metal detectors without setting them off. This is a major convenience for frequent travelers, FIFO (Fly-In, Fly-Out) workers, and anyone working in high-security facilities.

Comfort and Support Features

Modern composite boots are designed for comfort. They often include cushioned insoles, padded collars for ankle support, and breathable materials with linings that wick away sweat to keep your feet dry.

Understanding the Safety Standards

To ensure their effectiveness, safety boots must comply with strict national and international standards.

The ASTM F2413 Standard

In the United States, the key certification is ASTM F2413. This standard specifies the performance requirements for impact resistance, compression resistance, and electrical hazard protection.

International Certifications

Globally, these boots often meet other rigorous standards, such as EN ISO 20345 (European) and AS 2210.3 (Australian/New Zealand), making them a trusted choice worldwide.

Common Pitfalls and Trade-offs

While highly effective, it's important to understand the specific characteristics of composite materials to ensure you remain safe.

Bulk vs. Strength

To achieve the same strength rating as steel, a composite toe cap may need to be slightly bulkier. This can affect the fit and overall profile of the boot, though modern designs have largely minimized this difference.

Single Impact Resilience

This is a critical safety distinction. After a significant impact, a steel toe might bend, showing visible damage. A composite cap, however, can crack or fracture internally without any visible sign.

For this reason, a composite toe boot must be replaced immediately after experiencing a serious impact, as its protective structure may be compromised.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on the specific hazards and requirements of your work environment.

- If your primary focus is electrical safety or passing through metal detectors: The non-metallic, non-conductive properties of composite toe boots make them the definitive choice.

- If your primary focus is reducing fatigue and maximizing mobility: The lightweight nature of composite materials offers a significant advantage for workers who are constantly on the move.

- If your primary focus is protection in extreme impact zones: Ensure any boot, composite or steel, meets the required ASTM standard and always replace it after a significant impact event.

Ultimately, understanding these material properties empowers you to select safety footwear that precisely matches the demands of your job.

Summary Table:

| Protection Type | Key Benefit | Ideal For |

|---|---|---|

| Impact & Compression | Meets ASTM standards to protect toes from heavy objects | Construction, manufacturing, warehousing |

| Electrical Hazard (EH) | Non-conductive; protects against electrical shock up to 18,000V | Electricians, utility workers, industrial settings |

| Lightweight Design | Reduces foot fatigue for all-day comfort | Mobile workers, long shifts |

| Non-Metallic | Passes through metal detectors without issue | Security-sensitive sites, FIFO workers, airports |

| Slip & Puncture Resistance | Enhanced traction and underfoot protection | Oily, wet, or hazardous surfaces |

Need durable, certified safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and ISO-certified composite toe work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right combination of safety, comfort, and value.

Contact us today for competitive pricing and custom solutions tailored to your market's needs.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why are men's work boots not appropriate safety footwear for women? Key Fit & Safety Risks Explained

- Why is choosing the right outsole important for work boots? Maximize Safety and Traction

- What factors should be considered when choosing the right toe cap for work boots? Find Your Perfect Fit for Safety & Comfort

- How does Storm welt construction differ from Goodyear welt? A Guide to Superior Waterproofing

- What types of outfits can moc toe boots be worn with? Versatile Style Guide

- What role do anti-slip safety boots play in mitigating fall risks? Ensure Stability for High-Altitude Construction

- How does the height of PVC work boots affect protection? A Guide to Choosing the Right Boot for Your Job

- How can work boots be made suitable for winter? Master the 3-Pillar System for Warmth & Safety