Choosing the right work boot outsole is a foundational safety decision, not a minor detail. This single component is your primary point of contact with your work environment, directly determining your stability, protection, and even long-term comfort. The correct outsole is specifically engineered to provide the traction and resilience required for your unique job, preventing slips and ensuring the boot performs as intended for its entire lifespan.

The outsole of a work boot is not merely a layer of material; it is a piece of engineered safety equipment. The fundamental challenge is to correctly match the outsole's material and tread pattern to the specific surfaces and hazards you encounter daily.

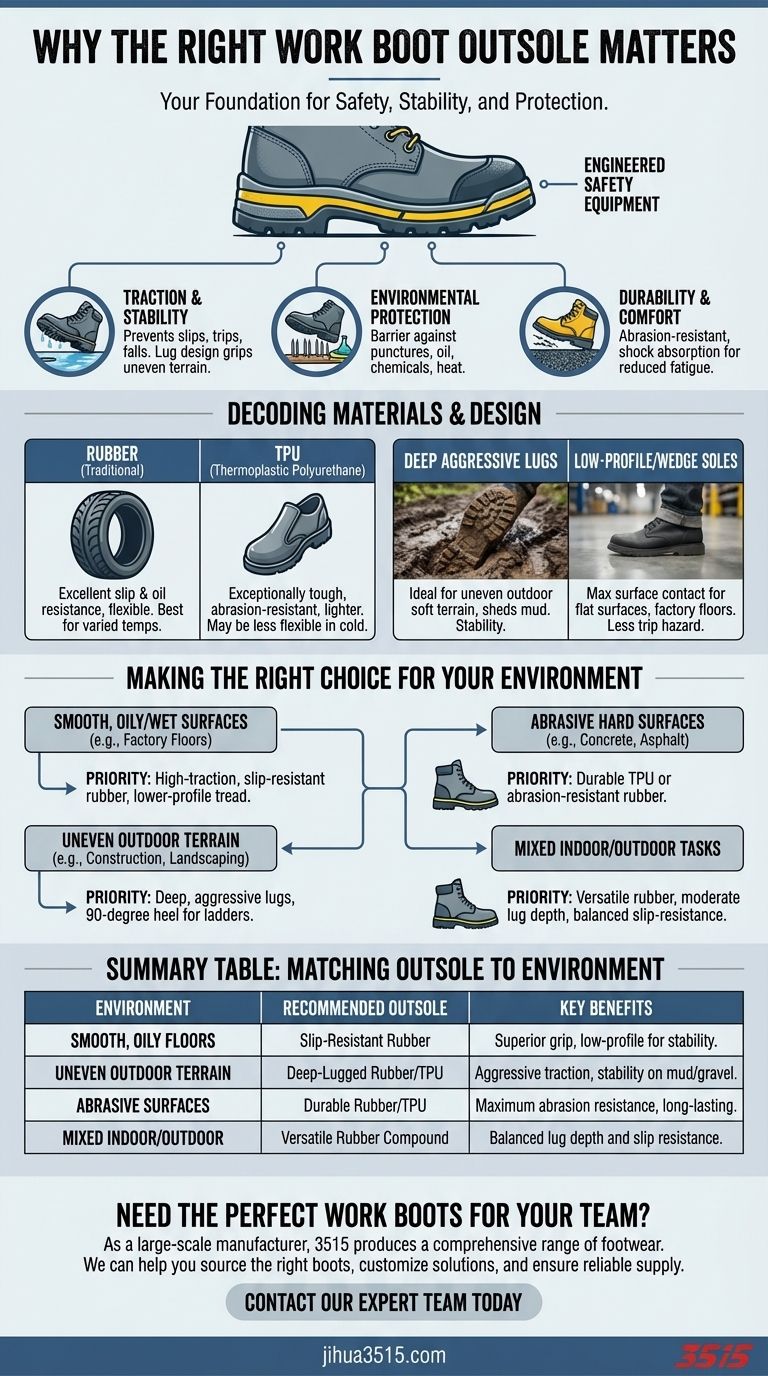

The Core Functions of an Outsole

An outsole must perform several critical jobs simultaneously. Understanding these functions clarifies why a one-size-fits-all approach is ineffective and often dangerous.

Ensuring Traction and Stability

The most obvious function of an outsole is to prevent slips, trips, and falls.

Traction is achieved through a combination of the material compound and the tread design, often called lugs. Deeper, wider-spaced lugs are designed to grip uneven terrain like mud and gravel, while shallower patterns provide more surface contact for stability on flat surfaces like concrete.

Providing Environmental Protection

Your outsole is a barrier between your foot and the ground.

It must protect you from common job site hazards, including punctures from sharp objects. Specific materials are also chosen for their resistance to oil, chemicals, or extreme heat, ensuring the sole doesn't degrade and fail when exposed to these elements.

Supporting Durability and Comfort

A boot is only as good as its weakest part, and the outsole takes the most direct abuse.

The material must be abrasion-resistant to avoid wearing down prematurely on rough surfaces like asphalt or concrete. Furthermore, the outsole's material contributes to shock absorption, reducing fatigue over a long day.

Decoding Outsole Materials and Design

The "right" outsole is determined by its construction. The two most important factors are the material compound and the tread pattern.

Common Materials: Rubber and TPU

Rubber is the traditional and most common choice for a reason. It offers an excellent balance of slip resistance, oil resistance, and flexibility across a wide range of temperatures.

TPU (Thermoplastic Polyurethane) is a more modern compound that is exceptionally tough and resistant to abrasion, splitting, and chemicals. It is often lighter than rubber but can become less flexible in extreme cold.

The Importance of the Lug Pattern

The grooves and channels of your outsole are not random; they are designed for specific environments.

Deep, aggressive lugs are ideal for outdoor work on soft surfaces, providing stability and shedding mud. Low-profile or wedge soles offer maximum surface contact, making them perfect for factory floors and other hard, flat surfaces where slips are the primary concern.

Understanding the Trade-offs

There is no single "best" outsole for every job. Every design choice involves a compromise, and understanding these trade-offs is key to selecting the right boot.

Grip vs. Durability

Softer rubber compounds provide outstanding traction, especially on smooth, wet surfaces. However, this softness means they will wear down more quickly.

Conversely, harder compounds like TPU offer exceptional lifespan and abrasion resistance but may provide less grip on slick flooring.

Specialization vs. Versatility

A boot with a highly specialized outsole, such as one designed for welders or roofers, will provide superior performance in that specific context.

However, these specialized features often make the boot less comfortable or practical for general-purpose use. A versatile, all-around outsole may not excel in any single area but provides reliable performance across varied tasks.

Making the Right Choice for Your Environment

Your daily work environment is the only factor that matters. Analyze the primary surfaces you walk on and the hazards you face to make a definitive choice.

- If you work on smooth, potentially oily or wet surfaces (e.g., auto shops, factory floors): Prioritize a high-traction rubber outsole with a slip-resistant rating and a lower-profile tread for maximum surface contact.

- If you work outdoors on uneven or soft terrain (e.g., construction, landscaping): Look for deep, aggressive lugs for superior stability and a defined 90-degree heel for safely climbing ladders.

- If you work primarily on abrasive hard surfaces (e.g., concrete, asphalt): Consider a durable TPU or a dense, abrasion-resistant rubber compound to maximize the lifespan of the boot.

- If your job involves a mix of indoor and outdoor tasks: A versatile rubber outsole that balances moderate lug depth with a good slip-resistance rating is your most practical choice.

Ultimately, viewing your boot's outsole as a critical piece of personal protective equipment is the first step toward a safer and more effective workday.

Summary Table:

| Work Environment | Recommended Outsole Type | Key Benefits |

|---|---|---|

| Smooth, Oily Floors | Slip-Resistant Rubber | Superior grip on wet surfaces, low-profile for stability. |

| Uneven Outdoor Terrain | Deep-Lugged Rubber/TPU | Aggressive traction, stability on mud/gravel, ladder-ready heel. |

| Abrasive Surfaces (Concrete) | Durable Rubber or TPU | Maximum abrasion resistance, long-lasting performance. |

| Mixed Indoor/Outdoor | Versatile Rubber Compound | Balanced lug depth and slip resistance for varied tasks. |

Need the perfect work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise outsoles your workforce needs for maximum safety and durability.

We can help you:

- Source the right boots for any work environment, from factories to construction sites.

- Customize solutions for your specific safety requirements and branding.

- Ensure reliable supply with our high-volume manufacturing capacity.

Contact our expert team today to discuss your work boot needs and get a quote.

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- How does arch support affect boot fitting? Unlock the Secret to a Perfect, Pain-Free Fit

- What are the key characteristics that make cowboy boots suitable for work? Uncover the Durability & Safety Features

- What are engineer boots and who commonly wears them? A Guide to This Iconic American Workwear

- How do oils help in waterproofing leather boots? Deep Conditioning & Protection

- What are some common safety risks associated with inadequate work boots? Protect Your Workforce from the Ground Up

- How do boots with ankle support enhance comfort? Achieve Stability and Reduce Fatigue

- What are the final thoughts on Western work boots? The Ultimate Hybrid for Durability & Style

- What factors should be considered when choosing work shoes? The Ultimate Guide to Safety & Comfort