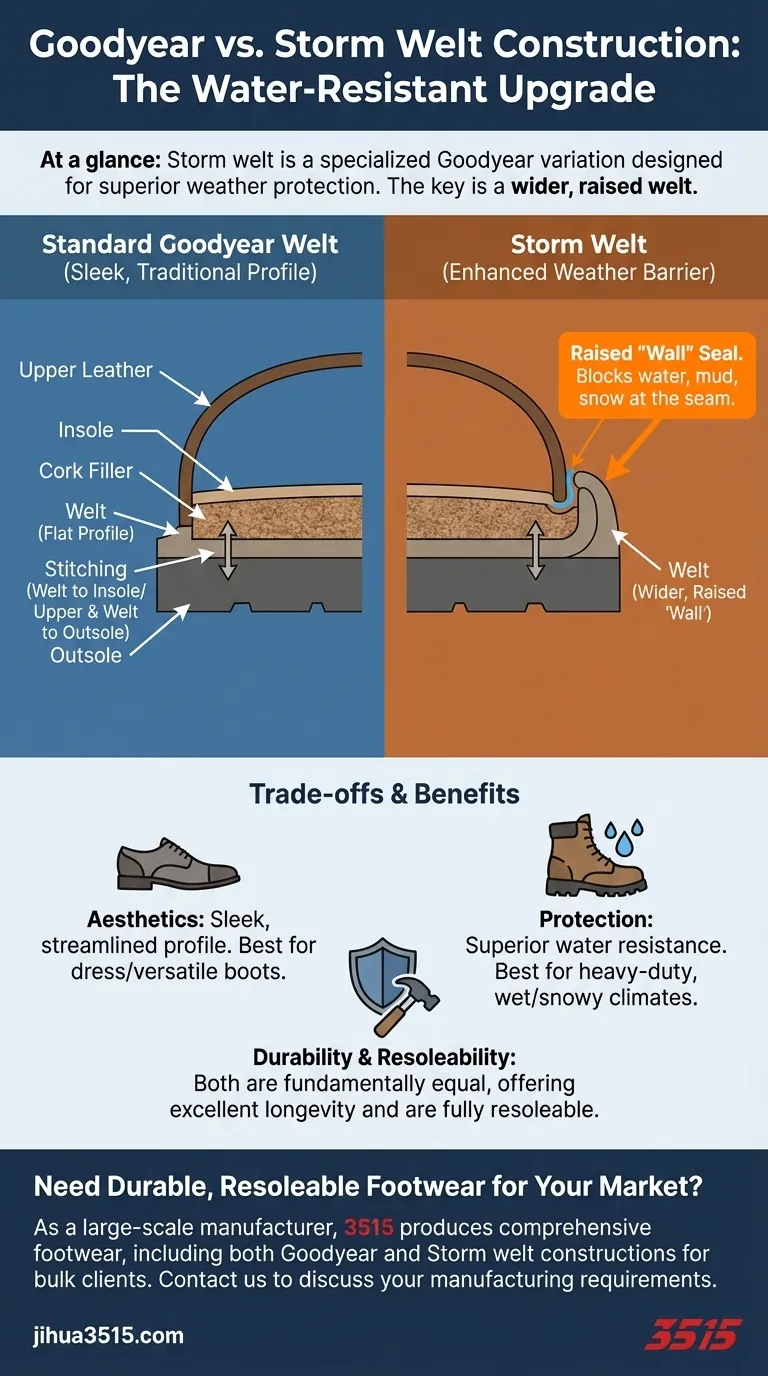

At a glance, a Storm welt is a specialized variation of the Goodyear welt, designed for superior water resistance. The fundamental difference lies in the welt's design; a Storm welt is wider and features a raised edge, or "wall," that curves up against the shoe's upper. This creates a more robust seal against moisture compared to the flatter, more traditional profile of a standard Goodyear welt.

The decision between a Storm welt and a standard Goodyear welt is a choice between maximizing weather protection versus achieving a more refined, traditional silhouette. Both methods signify high-quality, resoleable footwear, but the Storm welt is specifically engineered for harsher conditions.

The Foundation: Understanding the Goodyear Welt

A Goodyear welt is a hallmark of durable, well-made footwear. Understanding its basic construction is key to appreciating the Storm welt's specific advantages.

The Core Mechanism

In a Goodyear welted shoe, a strip of leather (the welt) is stitched to both the upper and the insole. The outsole is then stitched separately to this same welt.

This two-level stitching process creates an incredibly robust bond and a small cavity between the insole and outsole, which is typically filled with cork. This cork layer molds to your foot over time, providing exceptional comfort and support.

Key Benefits of the Standard

The primary benefits of this construction are durability and resoleability. Because the outsole is not stitched directly to the upper, a cobbler can easily remove the old sole and attach a new one without compromising the shoe's structure.

The Upgrade: How the Storm Welt Enhances Protection

The Storm welt takes the proven Goodyear system and adds a critical feature for weather-proofing. It is not a different method, but an enhancement.

A Purposeful Design Difference

The defining feature of a Storm welt is its extra width and a built-up, protective ridge. Unlike a standard Goodyear welt that lies mostly flat, a Storm welt is designed to be bent upwards.

This upward curve creates a small, protective wall that presses against the base of the footwear's upper.

The Functional Advantage: A Barrier to Entry

This "wall" forms a physical seal at the critical junction between the upper and the midsole. It effectively blocks water, mud, and snow from penetrating the seam.

While a standard Goodyear welt is water-resistant, the Storm welt provides a significantly higher degree of protection, making it ideal for footwear intended for foul weather.

Understanding the Trade-offs

Choosing between these two welt types involves balancing functional needs with aesthetic preferences. There is no single "better" option, only the right option for a specific purpose.

Water Resistance vs. Aesthetics

The Storm welt's primary advantage is superior moisture protection. This is its entire reason for being.

The trade-off is its appearance. The prominent ridge of a Storm welt creates a chunkier, more rugged look. A standard Goodyear welt provides a sleeker, more streamlined profile, making it more common on dress shoes and more formal boots.

Durability and Longevity

In terms of pure structural integrity and the ability to be resoled, both constructions are fundamentally equal. They are built on the same durable, two-level stitching principle.

Your choice will not impact how many times the footwear can be resoled or its general lifespan under normal conditions.

Making the Right Choice for Your Goal

Select your footwear's construction based on its intended environment and use.

- If your primary focus is maximum weather protection: Choose a Storm welt for its superior ability to seal out moisture, making it ideal for heavy-duty boots in wet or snowy climates.

- If your primary focus is a classic, versatile profile: Opt for a standard Goodyear welt, which offers excellent durability in a sleeker design suitable for everything from dress shoes to casual boots.

- If your primary focus is long-term value: Recognize that both methods deliver exceptional durability and the ability to be resoled, making either a sound investment in quality footwear.

Ultimately, understanding this construction detail allows you to select footwear engineered precisely for the conditions you will face.

Summary Table:

| Feature | Goodyear Welt | Storm Welt |

|---|---|---|

| Primary Advantage | Sleek, classic profile | Superior water resistance |

| Welt Design | Flatter, traditional profile | Wider with a raised, curved wall |

| Best For | Dress shoes, versatile boots | Heavy-duty boots for wet/snowy climates |

| Resoleability | Excellent | Excellent |

Need Durable, Resoleable Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both Goodyear welt and Storm welt constructions.

We can help you source the perfect footwear for your customers' needs, from classic styles to rugged, weather-ready boots.

Contact our team today to discuss your manufacturing requirements.

Visual Guide

Related Products

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How do oils help in waterproofing leather boots? Deep Conditioning & Protection

- What dual characteristics do industrial safety boots exhibit? Balance Worker Protection with Health Recovery Efficiency

- What are some characteristics of top-performing oil field boot brands? Built for Safety, Durability & Comfort

- Why is seamless construction important in PVC work boots? For Unbeatable Waterproof Protection

- How have cowboy boots evolved over time? From functional gear to fashion icon

- How should heavy duty work boots be maintained? Maximize Lifespan and Safety

- Can steel toe boots cause foot problems? Why Fit, Not the Steel, Is the Real Issue

- What historical factors affected engineer boot production? From WWII Workwear to Rebel Icon