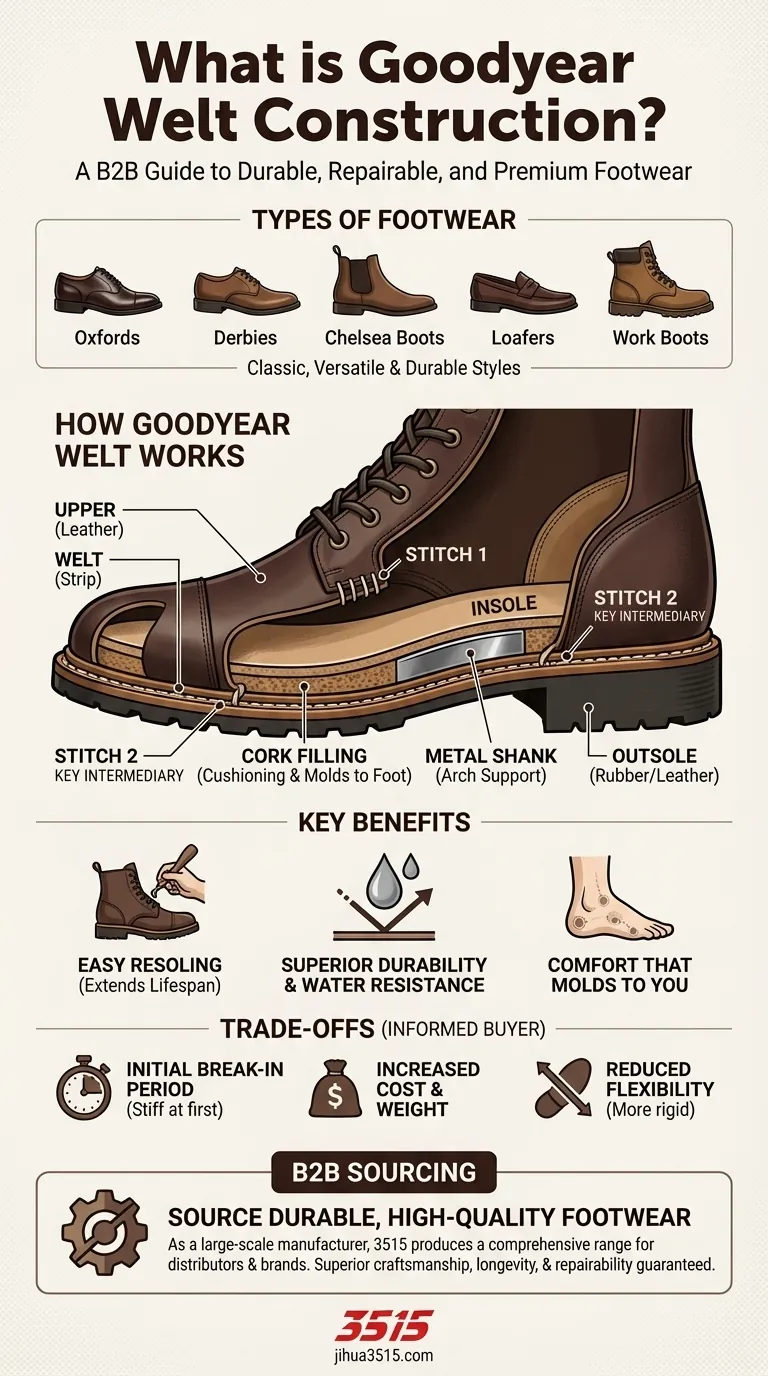

At its core, Goodyear welt construction is a hallmark of high-quality footwear, most commonly found in classic men's dress shoes like Oxfords and Derbies, versatile styles like Chelsea boots and loafers, and a wide range of durable work boots. This method is chosen for shoe types where durability, repairability, and longevity are paramount.

The specific style of shoe is less important than what the Goodyear welt signifies: a construction philosophy focused on creating a durable, water-resistant, and endlessly repairable piece of footwear designed to last for years, not just a season.

How Goodyear Welt Construction Works

To understand why this method is used in premium footwear, you must first understand the mechanics. It is a complex process that fundamentally separates the shoe's upper from the outsole.

The Key Components

A Goodyear welt is a strip of leather, rubber, or plastic that runs along the perimeter of the shoe. This welt acts as the crucial intermediary, connecting the upper to the outsole without directly puncturing the insole from the outside.

The construction also creates a cavity between the insole and outsole. This space is filled with a layer of granulated cork, which provides cushioning, breathability, and molds to the shape of your foot over time. A metal shank is often included for arch support and shape retention.

A Two-Level Stitching Process

The magic of the Goodyear welt is in its two independent stitches.

First, the shoe's upper is stitched to the welt and a canvas rib that is cemented to the insole. This securely attaches the top part of the shoe.

Second, the welt is then stitched to the outsole. This second, external stitch is what you see running along the edge of the sole, and it's the key to making the shoe easily repairable.

Why This Construction Method Matters

The choice to use a Goodyear welt is a commitment to a certain standard of quality. It directly results in several tangible benefits for the wearer.

The Power of Resoling

Because the outsole is stitched to the welt and not the upper, a cobbler can easily remove the old sole and stitch on a new one. This can be done multiple times without compromising the shoe's core structure, dramatically extending its lifespan.

Superior Durability and Water Resistance

The extra layers and stitching create an exceptionally robust and stable shoe. The welt acts as a barrier, making it more difficult for water to penetrate the shoe from the ground up compared to simpler construction methods.

Comfort That Molds to You

While often firmer out of the box, Goodyear welted shoes become uniquely comfortable over time. The cork-filled footbed gradually compresses and molds to the specific shape of your foot, creating a personalized fit that is impossible to replicate.

Understanding the Trade-offs

No construction method is perfect for every situation. Being an informed buyer means recognizing the potential downsides of this otherwise superior technique.

The Initial "Break-in" Period

The multiple layers and durable materials that make Goodyear welted shoes so tough also make them stiff at first. You should expect a break-in period as the leather and cork footbed soften and conform to your foot.

Increased Cost and Weight

The complexity of the process and the quality of materials required mean that Goodyear welted footwear is almost always more expensive and heavier than shoes with cemented soles.

Reduced Flexibility

Compared to a Blake-stitched or cemented shoe, a Goodyear welted shoe has less initial flexibility due to its layered construction. While this provides more support, it can feel more rigid, especially at first.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in Goodyear welted footwear depends on your priorities.

- If your primary focus is long-term value and repairability: Goodyear welt is the ideal choice, as it's specifically designed to be resoled and maintained for decades.

- If your primary focus is rugged durability for work or outdoor use: This construction excels in boots, providing the necessary stability and water resistance for demanding environments.

- If your primary focus is immediate, out-of-the-box comfort: Be prepared for a break-in period, or consider a more flexible construction if you need instant comfort.

Choosing a Goodyear welted shoe is an investment in a piece of footwear that is built to evolve with you.

Summary Table:

| Footwear Type | Key Characteristics | Ideal For |

|---|---|---|

| Oxfords & Derbies | Classic, formal appearance | Dress shoes, business attire |

| Chelsea Boots & Loafers | Versatile, stylish design | Casual and smart-casual wear |

| Work Boots | Rugged, heavy-duty build | Demanding environments, outdoor use |

Ready to source durable, high-quality footwear built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, ensuring superior craftsmanship, longevity, and repairability for your customers.

Contact us today to discuss your manufacturing needs and elevate your product line with footwear that stands the test of time.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the four levels of formality in dress shoes? A Guide to Color, Style & Material

- What are the origins and characteristics of Oxford shoes? Discover the Timeless Style

- What are the characteristics of classic cowboy boots? Discover the Purpose-Built Design

- Which dress shoe styles are suitable for wearing with jeans? A Guide to Smart-Casual Style

- What are the key rules for pairing cowboy boots with a suit? Master the Art of Confident Style

- Why is it necessary to establish a scientific Reorder Point (ROP) for the inventory management of dress shoes?

- What is the historical significance of the Goodyear Welted shoe construction method? Revolutionizing Durability & Craftsmanship

- Why is a shoe horn recommended for putting on leather shoes? Protect Your Investment & Maintain Shape