No, not all injection-molded work boots share the same drawbacks. The quality and performance of these boots depend heavily on the specific materials used, the complexity of the mold design, and the precision of the manufacturing process. While this construction method has inherent characteristics, a well-made boot can successfully mitigate many of the common complaints associated with its cheaper counterparts.

The term "injection-molded" describes a manufacturing process, not a monolith of quality. Understanding the difference between core materials like PVC and Polyurethane (PU) is the key to differentiating a stiff, low-performance boot from a durable and comfortable one.

What "Injection-Molded" Actually Means

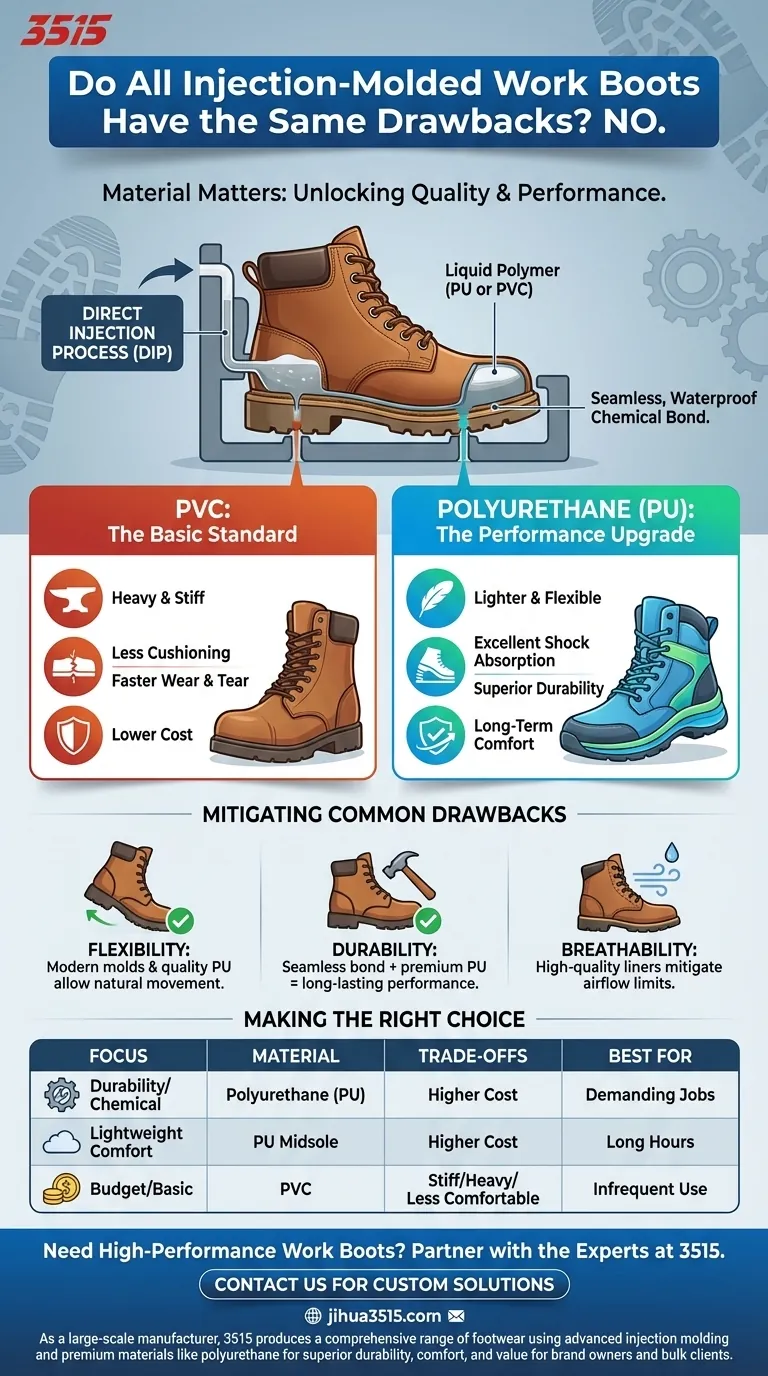

The term refers to a specific type of sole construction called Direct Injection Process (DIP). It's crucial to understand this process to see where variations in quality emerge.

The Fundamental Process

In the DIP method, the boot's upper (the part that covers your foot) is placed into a mold. A liquid polymer, such as polyurethane, is then injected into the mold under high pressure. This liquid polymer forms the sole and simultaneously creates an incredibly strong, seamless chemical bond with the upper as it cools and hardens.

Why This Method is Common

This manufacturing technique is prized for its efficiency and consistency in mass production. The primary benefit for the user is the waterproof seal created between the sole and the upper, as there are no stitches or glues that can fail.

The Material Makes the Difference

The negative reputation of injection-molded boots often stems from products made with the cheapest available materials. The choice of polymer is the single most important factor in the boot's performance.

Polyvinyl Chloride (PVC): The Basic Standard

PVC is a very common, low-cost material used in entry-level injection-molded boots. It is the source of many of the style's drawbacks.

PVC is known for being relatively heavy and stiff, especially in cold weather. It offers less cushioning and is less resistant to abrasion and chemical breakdown than more advanced materials.

Polyurethane (PU): The Performance Upgrade

Polyurethane is a significantly superior material. It is lighter, more flexible, and far more durable than PVC.

PU offers excellent shock absorption and will maintain its shape and cushioning properties for much longer. High-end boots often use dual-density PU, injecting a softer PU for a cushioned midsole and a tougher, denser PU for a rugged outsole.

Common Drawbacks and How They Are Mitigated

By understanding the materials, we can see that the common complaints are not universal to the injection-molded process itself, but are often symptoms of cost-cutting material choices.

The Myth of Inflexibility

While cheap PVC boots are notoriously stiff, a boot made with a high-quality, properly formulated polyurethane sole can be very flexible. Modern mold designs also incorporate strategic flex points to improve the natural movement of the foot.

The Question of Durability

The seamless bond created by injection molding is actually a major durability advantage, eliminating the risk of sole separation. The weak point is the material itself. A PVC sole will wear down much faster and is more prone to cracking than a properly engineered PU sole.

The Challenge of Breathability

This is one inherent trade-off of the construction. The waterproof, seamless bond that makes injection-molded boots so effective in wet environments also limits airflow. Reputable manufacturers mitigate this with high-quality moisture-wicking liners and breathable upper materials, but it will never be as breathable as a boot with a stitched-on sole.

Making the Right Choice for Your Needs

Your goal should be to match the boot's materials to the demands of your job.

- If your primary focus is maximum durability and chemical resistance: Seek out boots specifying a single or dual-density Polyurethane (PU) outsole.

- If your primary focus is lightweight comfort for long hours on your feet: Prioritize boots that use a PU midsole for lasting cushioning, which is far superior to basic PVC.

- If your primary focus is budget and basic waterproof protection for infrequent use: A PVC-injected boot will suffice, but you must accept the trade-offs in flexibility, weight, and long-term comfort.

By looking past the construction method and focusing on the materials used, you can select an injection-molded boot that truly meets your performance demands.

Summary Table:

| Material | Key Characteristics | Common Drawbacks | Mitigation |

|---|---|---|---|

| PVC | Low-cost, basic waterproofing | Heavy, stiff, less durable | Suitable for infrequent, low-budget use |

| Polyurethane (PU) | Lighter, flexible, durable, better cushioning | Higher cost | Excellent for demanding jobs and long-term comfort |

| Dual-Density PU | Combines cushioned midsole with rugged outsole | Premium price | Optimal performance for heavy-duty applications |

Need high-performance work boots tailored to your specific job demands?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in advanced injection molding with premium materials like polyurethane ensures your boots deliver superior durability, comfort, and value.

Contact our team today to discuss your custom work boot requirements and discover how we can enhance your product line.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- How can the right boot choice enhance work performance? Boost Safety, Comfort, and Endurance

- How can the lifespan of PVC boots be extended? Protect Your Investment with Simple Care

- What is the benefit of effective insulation in work boots? Boost Health, Safety, and Performance

- What are the key ASTM standards for work boots? Your Guide to Certified Footwear Safety

- Why are certifications important for firefighter boots? Your Non-Negotiable Safety Guarantee

- Why is traction important in oilfield boots? Prevent Slips and Falls on Hazardous Terrain

- How does high ankle support improve work boot performance? Prevent Sprains & Boost Stability

- How do some boots combine materials for better performance? Achieve Superior Safety & Comfort