For foundry work, you need specialized footwear designed explicitly to protect against extreme heat and molten metal splashes. Standard safety boots are insufficient and dangerous in this environment; true foundry boots incorporate specific materials and design features to handle the unique thermal hazards.

The single most important factor is the boot's ability to protect against catastrophic heat and molten metal. This requires specific features like metatarsal guards, heat-resistant outsoles, and quick-release fastenings, which are not found on typical work boots.

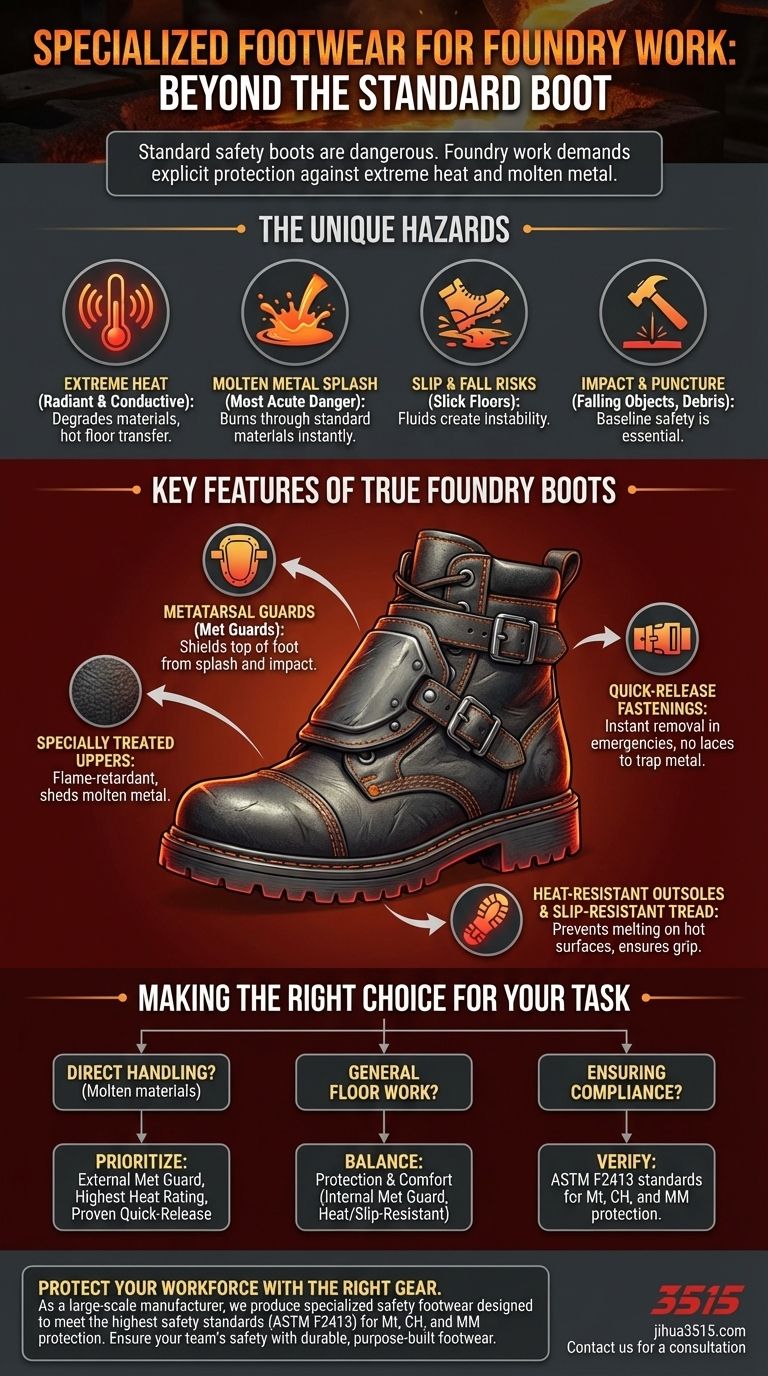

The Unique Hazards of a Foundry Environment

Understanding the specific risks is the first step in selecting the correct personal protective equipment (PPE). A foundry presents a combination of dangers that demand more than standard protection.

Extreme Radiant and Conductive Heat

The entire environment is saturated with high heat, which can degrade boot materials and transfer dangerously to the foot. The floor itself can be extremely hot, requiring specialized soles to prevent burns and material failure.

Molten Metal Splash

This is the most acute danger. A splash of molten metal can adhere to and burn through standard leather or synthetic materials in seconds. The footwear must be designed to shed these splashes immediately.

Slip and Fall Risks

Foundry floors can become slick with water, oils, or other industrial fluids. A slip-resistant outsole is crucial for maintaining stability and preventing falls in this high-risk area.

Impact and Puncture

Like many industrial sites, the risk of falling objects or stepping on sharp debris is ever-present. Protective safety toes and puncture-resistant plates remain essential baseline features.

Key Features of True Foundry Boots

To counter these hazards, foundry boots are engineered with specific protective technologies. Look for these non-negotiable features.

Metatarsal Guards (Met Guards)

An external shield, often made of high-impact material covered in heat-resistant fabric, covers the top of the foot (the metatarsal bones) and the laces. This is the primary defense against molten metal splashes.

Heat-Resistant Outsoles

The outsole must be made from a rubber compound specifically rated for high heat. This prevents the sole from melting, deforming, or transferring heat to the foot when walking on hot surfaces.

Quick-Release Fastenings

Foundry boots must not have traditional laces, which can trap molten metal and are too slow to undo in an emergency. Instead, they use systems like quick-release buckles or elasticated leather covers (goring) so the boot can be removed almost instantly if a splash gets inside.

Specially Treated Uppers

The main body of the boot is typically made from thick, durable leather or other materials that have been treated to be flame-retardant and shed molten metal. The stitching also uses high-heat-resistant thread, like Kevlar, to prevent seams from failing.

Slip-Resistant Tread

The outsole should feature a deep, well-defined tread pattern designed to channel away liquids and maintain a firm grip on potentially slippery surfaces. This is critical for preventing falls that could lead to contact with hot materials.

Understanding the Trade-offs

Selecting the right boot involves balancing maximum protection with practical considerations for daily wear.

Protection vs. Comfort

Boots with the highest level of protection, such as those with heavy external met guards, can be stiffer and heavier. While essential for high-risk tasks, they may cause fatigue during long shifts compared to more flexible designs.

Cost as an Investment

Specialized foundry boots are significantly more expensive than standard work boots. This higher cost reflects the advanced materials and safety technologies required. Viewing this as a necessary investment in safety, not an expense, is the correct approach.

Durability and Inspection

The intense heat and harsh conditions of a foundry will wear out boots faster than a typical work environment. Regular, thorough inspection for cracks, compromised seams, or worn-out soles is critical for ensuring continued protection.

Making the Right Choice for Your Task

Your specific role and proximity to molten material will guide your final selection.

- If your primary focus is direct handling of molten materials: Prioritize boots with external metatarsal guards, the highest available heat rating, and a proven quick-release system.

- If your primary focus is general work on the foundry floor: A boot with an internal metatarsal guard, heat-resistant soles, and slip-resistant treads provides a good balance of safety and comfort.

- If your primary focus is ensuring compliance: Always verify that the footwear meets or exceeds relevant safety standards (e.g., ASTM F2413) for Metatarsal (Mt), Conductive Heat (CH), and Molten Metal (MM) protection.

Ultimately, investing in the correct, purpose-built foundry boot is a critical decision that directly protects against life-altering injuries.

Summary Table:

| Key Feature | Purpose |

|---|---|

| Metatarsal Guards | Protects the top of the foot from molten metal splash and impact. |

| Heat-Resistant Outsoles | Prevents melting and heat transfer from hot floors. |

| Quick-Release Fastenings | Allows for instant removal in an emergency. |

| Specially Treated Uppers | Flame-retardant materials that shed molten metal. |

| Slip-Resistant Tread | Provides stability on slick, industrial floors. |

Protect your workforce with the right gear. As a large-scale manufacturer, 3515 produces a comprehensive range of specialized safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of foundry boots designed to meet the highest safety standards (ASTM F2413) for Mt, CH, and MM protection. Ensure your team's safety with durable, purpose-built footwear—contact us today for a consultation and see how we can meet your specific needs.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are some technical features available in safety shoes? A Guide to Workplace Foot Protection

- How does the upper material of a safety boot affect safety and comfort? Find the Right Shield for Your Feet

- How do the 3R principles influence green footwear design? Master Sustainable Safety Shoe Manufacturing

- What are the pros and cons of lace-up work shoes? Maximize Safety vs. Convenience

- Why use steel surfaces for industrial footwear anti-slip testing? Ensuring Grip in High-Risk Environments

- What role does impact resistance play in the technical specifications of safety shoes for shipyard welders and assemblers? Ensure Ultimate Protection & Endurance

- Why incorporate plantar pressure in gait analysis? Enhance Design and Accuracy for Tactical & Safety Footwear

- How does constant temperature control affect the results of safety shoe slip resistance testing? Ensure Lab Precision