At their core, safety shoes are defined by their technical features. These commonly include a reinforced safety toecap (steel or composite), a slip-resistant outsole, and protection against specific workplace hazards such as punctures, electrical shock, and water intrusion. Modern safety footwear combines these protective elements with features designed for comfort, like cushioned insoles and breathable uppers.

The most critical insight is that safety shoes are not a one-size-fits-all solution. The right features are dictated entirely by the specific hazards of your work environment; understanding these hazards is the first step to selecting the correct protection.

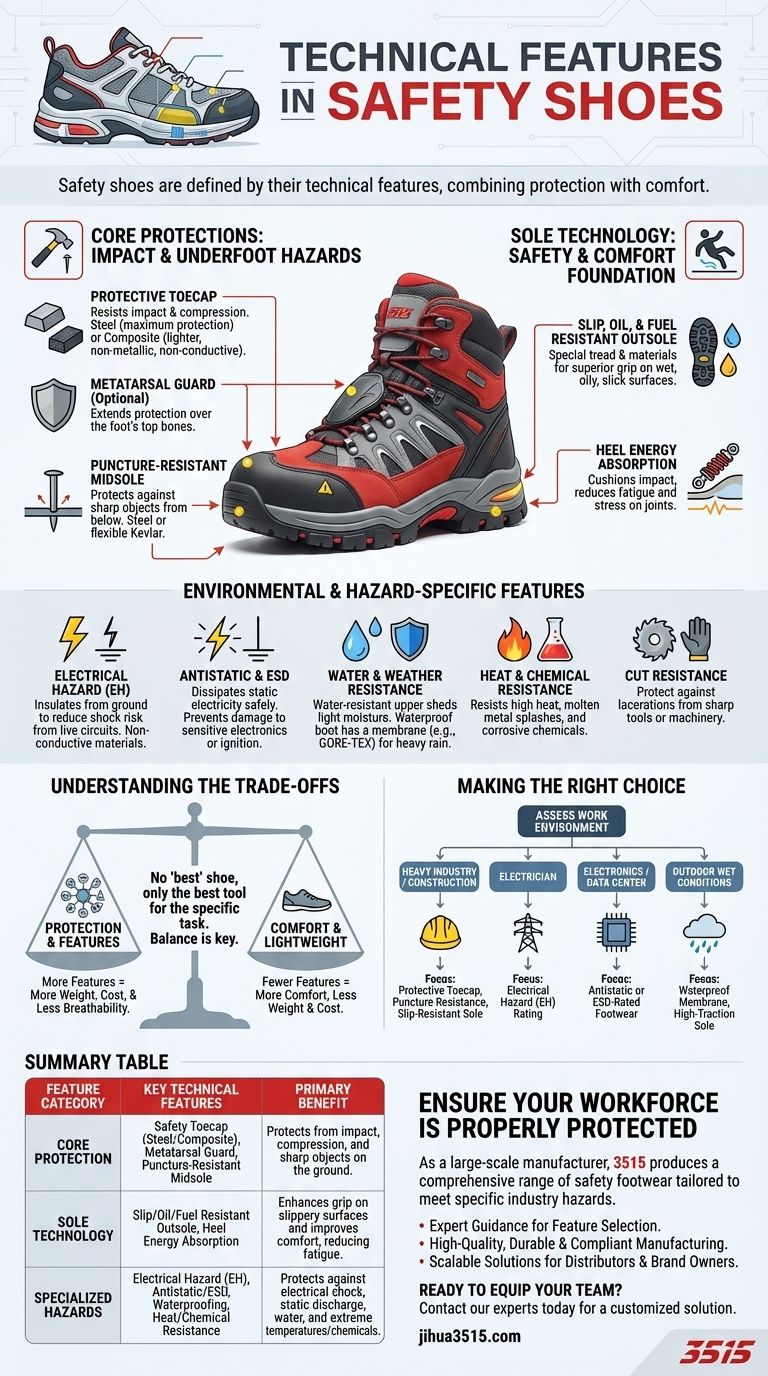

Core Protections: Impact and Underfoot Hazards

The foundational purpose of a safety shoe is to protect your feet from the most common physical threats in a work environment: falling objects and sharp items on the ground.

The Protective Toecap

The most recognizable feature of any safety shoe is its reinforced toecap, designed to resist both impact and compression.

There are two primary types: steel toecaps, the traditional standard known for maximum protection, and composite toecaps, which are lighter, non-metallic, and do not conduct heat or cold.

Metatarsal Support

For even greater protection, some boots include metatarsal guards. These extend protection from the toecap up over the top of the foot, shielding the delicate metatarsal bones from impact.

Puncture Resistance

A puncture-resistant midsole is a critical feature for environments with nails, screws, or other sharp debris. These are typically made of steel or flexible composite materials like Kevlar.

Sole Technology: The Foundation of Safety and Comfort

The outsole and midsole are where many of the most important technical features reside, directly impacting grip, stability, and long-term comfort.

Slip, Oil, and Fuel Resistance

A slip-resistant outsole is mandatory in many industries. These soles are engineered with specific tread patterns and materials to provide superior grip on wet, oily, or slick surfaces.

Many are also specifically rated as oil and fuel resistant, ensuring the sole material does not degrade or lose traction when exposed to hydrocarbons.

Heel Energy Absorption

This feature is designed for comfort and the reduction of fatigue. An energy-absorbing heel cushions the impact of each step, reducing stress on your feet, ankles, and spine over a long workday.

Environmental and Hazard-Specific Features

Beyond physical impacts, safety shoes are engineered to protect against a range of environmental and specialized workplace hazards.

Electrical Hazard (EH) Protection

Electrical Hazard (EH) rated shoes are made with non-conductive materials and are designed to insulate the wearer from the ground, reducing the risk of electric shock from accidental contact with live circuits.

Antistatic and Electrostatic Dissipative (ESD)

Unlike EH shoes, antistatic and ESD footwear is designed to safely dissipate static electricity from the body to the ground. This is crucial in environments where a static spark could damage sensitive electronics or ignite flammable materials.

Water and Weather Resistance

There is a key distinction between "water resistant" and "waterproof." A water-resistant upper can shed light moisture, while a truly waterproof shoe features a membrane liner, like GORE-TEX, to keep feet dry in heavy rain or standing water.

Heat and Chemical Resistance

For extreme environments like foundries or chemical plants, specialized boots are made with materials that resist high heat, molten metal splashes, and corrosive chemical substances.

Cut Resistance

In industries that use sharp tools or machinery, such as glass handling or logging, boots can be made with cut-resistant materials to protect against lacerations.

Understanding the Trade-offs

Selecting safety footwear always involves balancing competing priorities. There is no single "best" shoe, only the best shoe for a specific task.

Protection vs. Weight and Comfort

Generally, higher levels of protection (like steel toes and midsoles) add weight. While composite materials help, a heavily armored boot can be more fatiguing to wear over a 12-hour shift than a lighter-duty alternative.

Breathability vs. Waterproofing

A fully waterproof boot with a sealed membrane will inherently be less breathable than a shoe with a mesh or leather upper. This can lead to hot, sweaty feet in warm conditions, creating a trade-off between staying dry from the outside and staying dry from the inside.

Cost vs. Specialized Features

Each additional technical feature adds to the complexity and cost of the shoe. A basic steel-toe boot will be far more affordable than a fully waterproof, EH-rated, composite-toe boot with a puncture-resistant midsole.

Making the Right Choice for Your Goal

Your choice must be driven by a clear assessment of your daily work environment.

- If your primary focus is heavy industry or construction: Prioritize a protective toecap (steel or composite), puncture resistance, and a slip-resistant outsole.

- If your primary focus is working as an electrician: You must select footwear with a clear Electrical Hazard (EH) rating to ensure insulation.

- If your primary focus is electronics manufacturing or a data center: Antistatic or ESD-rated footwear is non-negotiable to protect sensitive equipment.

- If your primary focus is outdoor work in wet conditions: A waterproof membrane is essential, combined with a high-traction, slip-resistant sole.

Ultimately, choosing the right safety shoe is about matching the tool to the task to ensure your feet are protected, comfortable, and secure.

Summary Table:

| Feature Category | Key Technical Features | Primary Benefit |

|---|---|---|

| Core Protection | Safety Toecap (Steel/Composite), Metatarsal Guard, Puncture-Resistant Midsole | Protects from impact, compression, and sharp objects on the ground. |

| Sole Technology | Slip/Oil/Fuel Resistant Outsole, Heel Energy Absorption | Enhances grip on slippery surfaces and improves comfort, reducing fatigue. |

| Specialized Hazards | Electrical Hazard (EH), Antistatic/ESD, Waterproofing, Heat/Chemical Resistance | Protects against electrical shock, static discharge, water, and extreme temperatures/chemicals. |

Ensure Your Workforce is Properly Protected

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to meet the specific hazards of your industry.

Partner with us to benefit from:

- Expert Guidance: We help you select the right combination of technical features for your specific work environment.

- High-Quality Manufacturing: Durable, compliant, and comfortable safety footwear built to last.

- Scalable Solutions: Reliable supply for distributors and custom options for brand owners.

Ready to equip your team with the right protection? Contact our experts today to discuss your safety footwear needs and receive a customized solution.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the primary technical advantages of using Polyurethane (PUR) materials in safety footwear? Durability & Comfort

- What role does material play in work shoes? Choose the Right System for Safety & Comfort

- Why is professional footwear considered a vital component of PPE in hotel safety? Ensure Maximum Staff Protection

- What are the advantages of alloy toe boots? Lighter, More Comfortable Safety Footwear

- What is the role of leather processing drums in preventing hexavalent chromium? Achieve Non-Toxic Safety Shoe Leather

- Why is a high-precision digital dynamometer necessary for measuring the slip safety coefficient of footwear materials? Ensure Unrivaled Slip Prevention & Accuracy

- Why is slip-resistance a critical feature for safety shoes used in insecticide spraying? Prevent Workplace Falls

- What are the main hazards that safety footwear is designed to protect against? A Guide to Essential Foot Protection