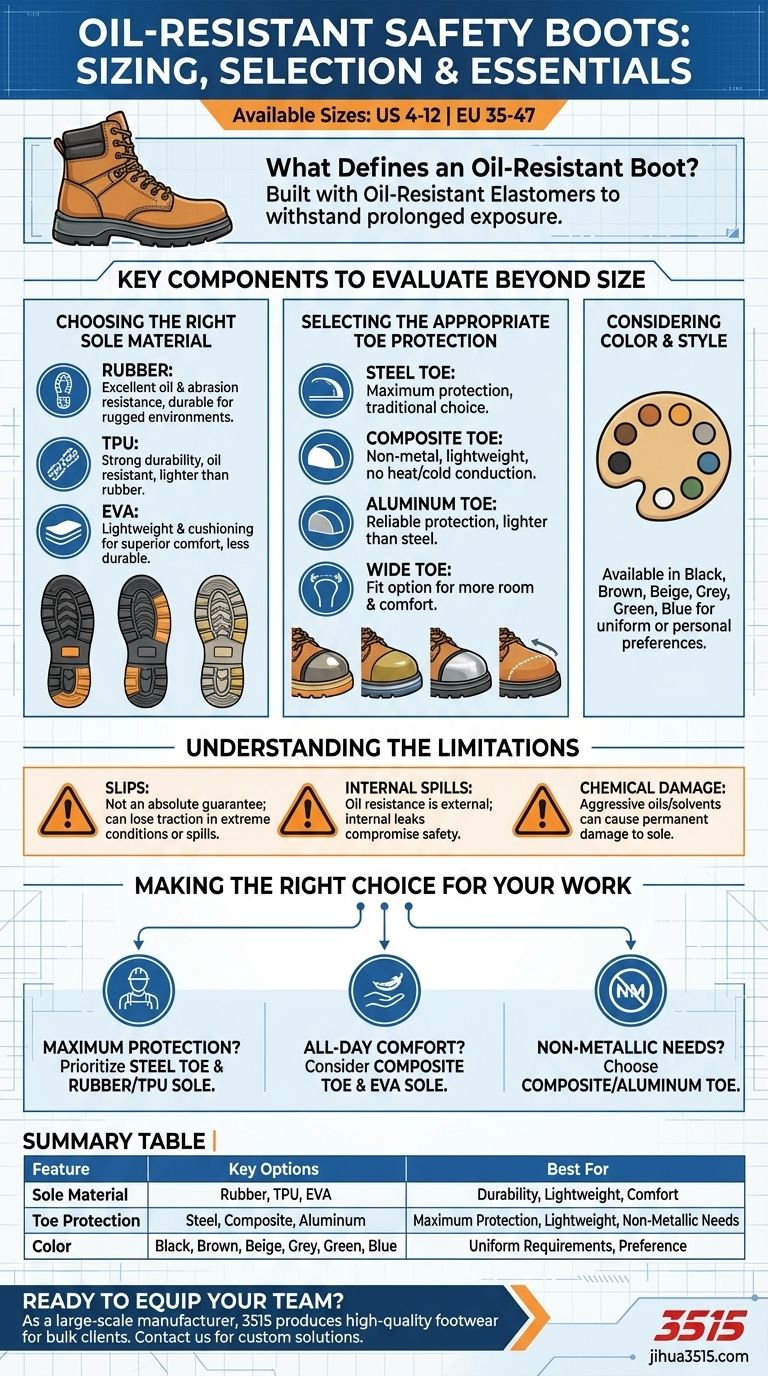

Regarding available sizes, oil-resistant safety boots are typically offered in a standard range that covers most professional needs. You can generally find them in US sizes from 4 to 12 and in European sizes from 35 to 47.

While finding the correct size is the first step, selecting the right oil-resistant safety boot truly depends on understanding the specific materials used for the sole and toe protection. The optimal choice aligns these components with the unique demands and risks of your work environment.

What Defines an Oil-Resistant Boot?

The Role of Specialized Materials

True oil-resistant footwear is designed to withstand prolonged exposure to oil without degrading. This is achieved by using oil-resistant elastomers in the sole's construction.

These materials ensure the boot maintains its structural integrity and protective qualities, especially when exposed to oils at elevated temperatures found in many industrial settings.

Key Components to Evaluate Beyond Size

Choosing the right boot involves a careful assessment of its core components. The materials used directly impact its safety, durability, and comfort.

Choosing the Right Sole Material

The sole is the boot's primary defense against workplace hazards.

- Rubber: Offers excellent resistance to oil and abrasion, making it highly durable for rugged environments.

- Thermo-Polyurethane (TPU): Provides a strong combination of durability and oil resistance, often lighter than rubber.

- Ethylene-Vinyl Acetate (EVA): Known for its light weight and cushioning, providing superior comfort for long shifts, though it may be less durable than rubber or TPU.

Selecting the Appropriate Toe Protection

The safety toe is a critical feature for protecting against impact and compression.

- Steel Toe: The traditional choice, offering maximum protection.

- Composite Toe: Made from non-metal materials like carbon fiber or plastic, these are lighter and do not conduct heat or cold.

- Aluminum Toe: Provides reliable protection while being lighter than steel.

- Wide Toe: This is a fit option available across toe types, offering more room and comfort for those with wider feet.

Considering Color and Style

While functionality is paramount, these boots are also available in a variety of colors to meet uniform or personal preferences. Common options include black, brown, beige, grey, and various shades of green and blue.

Understanding the Limitations

Even the highest quality boots have practical limitations that you must be aware of to ensure your safety.

Not an Absolute Guarantee Against Slips

Despite having non-slip features, these boots can still lose traction in extremely slippery conditions or on surfaces with significant, unmanaged spills.

Vulnerability to Internal Spills

The oil-resistant protection is on the boot's exterior. If oils or other chemicals leak or spill inside the boot, its effectiveness and internal components can be compromised.

Potential for Permanent Damage

While resistant, the non-slip surface of the sole is not invincible. Certain aggressive oils or chemical solvents can cause permanent damage, reducing the boot's safety performance over time.

Making the Right Choice for Your Work

Selecting the correct boot means matching its features to your specific job requirements.

- If your primary focus is maximum protection in heavy-duty environments: Prioritize boots with a steel toe and a durable rubber or TPU sole.

- If your primary focus is all-day comfort and mobility: Consider a lighter composite toe paired with a cushioned EVA sole.

- If your primary focus is balancing protection with non-metallic requirements: A composite or aluminum toe is the ideal choice for passing through metal detectors or working near electrical hazards.

By looking beyond size and evaluating these core components, you can confidently select a boot that delivers both safety and performance.

Summary Table:

| Feature | Key Options | Best For |

|---|---|---|

| Sole Material | Rubber, TPU, EVA | Durability, Lightweight, or Comfort |

| Toe Protection | Steel, Composite, Aluminum | Maximum Protection, Lightweight, or Non-Metallic Needs |

| Color | Black, Brown, Beige, Grey, Green, Blue | Uniform Requirements or Personal Preference |

Ready to equip your team with the perfect oil-resistant safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. We can help you select or customize boots with the right combination of oil-resistant soles, toe protection, and comfort features for your specific work environment.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What role do professional safety shoes play in addressing balance and gait issues? Enhance Workplace Stability and Confidence

- What are key scenarios requiring safety footwear? Protect Your Workforce from Hazards

- How can one choose the best firefighter boots? A Guide to NFPA-Certified Safety & Performance

- What are the key traits of good safety footwear? Protect Your Workforce with Durable, All-Day Comfort

- What is unique about a carbon composite toe? Maximum Protection with Minimal Weight

- What role does an adjustable industrial actuator play in slip resistance? Enhance Safety Shoe Testing Precision

- What are the safety advantages of slip-on boots? Quick-Removal & Snag-Free Design for Hazardous Work

- What are the benefits of using EVA in safety boots? Enhance Comfort and Reduce Fatigue