At its core, safety footwear is required in any environment where foot injuries can occur from falling or rolling objects, punctures, chemical spills, or electrical hazards. Key scenarios include construction sites, manufacturing floors with moving machinery, warehouses where heavy objects are lifted, and environments with slippery surfaces or hazardous chemicals.

Safety footwear is not merely a precaution; it is a critical engineering control mandated by regulators like OSHA to mitigate specific, identified workplace hazards. Understanding the type of hazard you face is the essential first step to selecting the correct, compliant protection.

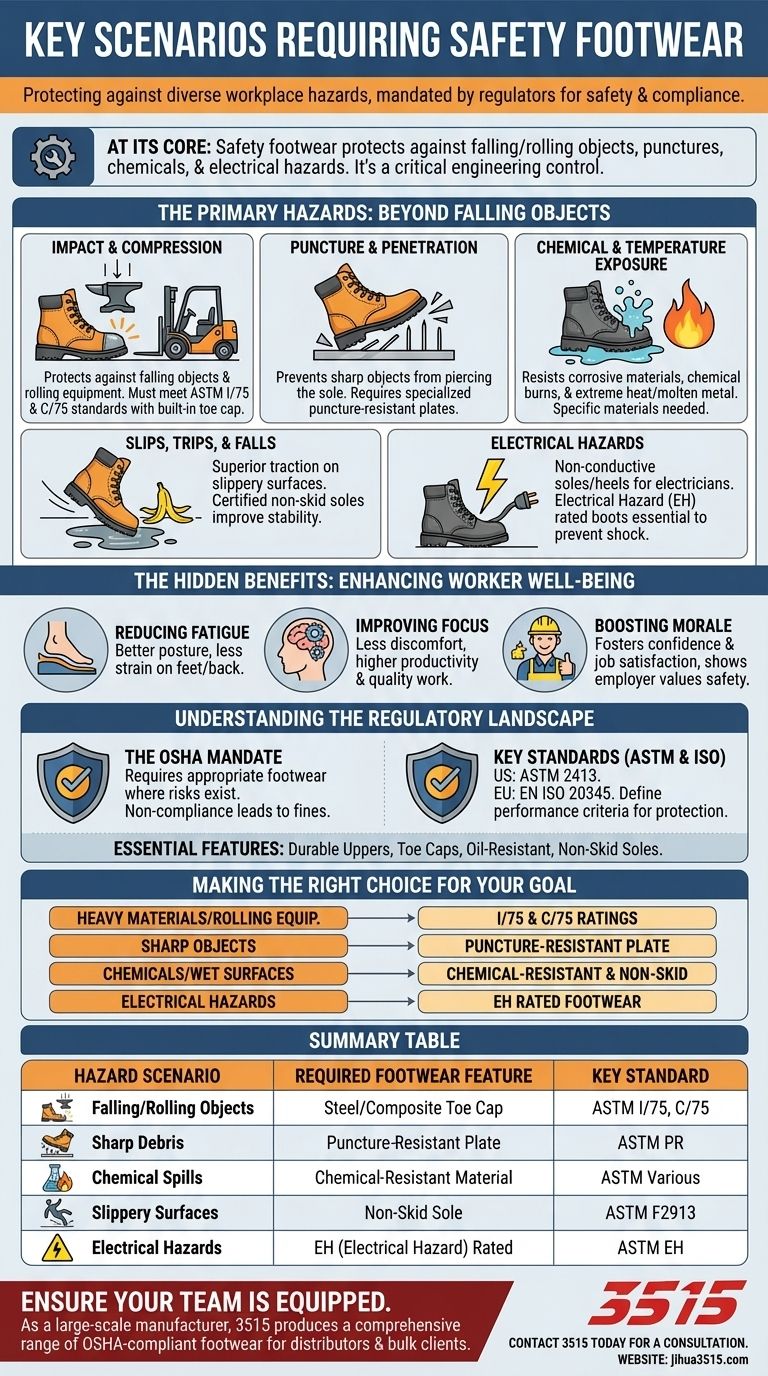

The Primary Hazards: Beyond Falling Objects

While the classic image is a steel-toed boot protecting against a dropped weight, the risks that necessitate safety footwear are far more diverse. Each hazard requires a specific type of protection.

Impact and Compression Risks

This is the most recognized function of safety footwear. It addresses dangers from falling objects like tools or materials, as well as the risk of feet being run over by rolling equipment like carts or forklifts.

OSHA-compliant footwear must meet specific ASTM standards for impact (I/75) and compression (C/75) resistance, which is provided by a mandatory built-in toe cap.

Puncture and Penetration Dangers

Construction sites, demolition zones, and maintenance areas often have sharp objects like nails, screws, or metal shards on the ground.

Footwear with specialized puncture-resistant plates in the sole is designed to prevent these objects from penetrating the bottom of the foot.

Chemical and Temperature Exposure

Workers handling corrosive or hazardous materials need footwear made from materials that can resist chemical burns, degradation, and permeation.

Similarly, in environments with extreme heat, specialized boots protect against burns from molten metal or hot surfaces.

Slips, Trips, and Falls

Slips are one of the most common workplace accidents. Safety footwear with certified non-skid soles provides superior traction on wet, oily, or otherwise slippery surfaces, dramatically improving stability.

Electrical Hazards

For electricians or maintenance personnel working near live circuits, Electrical Hazard (EH) rated boots are essential. They are designed with non-conductive soles and heels to protect the wearer from electric shock.

The Hidden Benefits: Enhancing Worker Well-being

Properly specified safety footwear does more than just prevent injury; it contributes directly to a healthier and more productive workforce.

Reducing Physical Fatigue

Safety footwear that is well-designed provides essential arch support and cushioning. This improves posture and reduces the physical strain on the feet, legs, and back over a long shift.

Improving Focus and Productivity

When workers feel safe and are not suffering from physical fatigue, their focus naturally improves. This reduction in distraction and discomfort leads to higher quality work and greater overall productivity.

Boosting Morale and Confidence

Providing high-quality Personal Protective Equipment (PPE) sends a clear message that an employer values the safety and well-being of its team. This fosters confidence, boosts job satisfaction, and improves morale.

Understanding the Regulatory Landscape

Workplace safety is not optional. Regulatory bodies mandate the use of protective footwear in environments where hazards have been identified.

The OSHA Mandate

The Occupational Safety and Health Administration (OSHA) requires employers to ensure that personnel wear appropriate protective footwear in any work area with a risk of foot injury.

Failure to comply can result in significant fines and, more importantly, preventable accidents.

Key Footwear Standards (ASTM & ISO)

To be considered compliant in the United States, safety footwear must meet standards set by ASTM International (ASTM 2413). The European equivalent is EN ISO 20345.

These standards define the specific performance criteria for impact resistance, compression resistance, and other protective features.

Essential Features of Compliant Footwear

According to OSHA and ASTM standards, approved safety footwear typically includes a combination of features like durable leather uppers, mandatory built-in toe caps, oil-resistant materials, and certified non-skid soles.

Making the Right Choice for Your Goal

Selecting the correct footwear requires matching the shoe's specific features to the hazards of your work environment.

- If your primary risk is heavy materials or rolling equipment: Ensure your footwear has the highest impact (I/75) and compression (C/75) ratings.

- If you work with sharp objects or construction debris: Prioritize footwear with a built-in, puncture-resistant sole plate.

- If you are exposed to chemicals or wet surfaces: Emphasize footwear made of chemical-resistant materials and possessing certified, high-traction non-skid soles.

- If you face electrical hazards: You must select footwear specifically marked with an Electrical Hazard (EH) rating.

Investing in the right safety footwear is a foundational investment in personal safety and operational excellence.

Summary Table:

| Hazard Scenario | Required Footwear Feature | Key Standard |

|---|---|---|

| Falling/Rolling Objects | Steel/Composite Toe Cap | ASTM I/75, C/75 |

| Sharp Debris (nails, glass) | Puncture-Resistant Plate | ASTM PR |

| Chemical Spills | Chemical-Resistant Material | ASTM Various |

| Slippery Surfaces | Non-Skid Sole | ASTM F2913 |

| Electrical Hazards | EH (Electrical Hazard) Rated | ASTM EH |

Ensure your team is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of OSHA-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet ASTM standards. We help you protect your workforce, enhance productivity, and maintain compliance. Contact 3515 today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What factors affect the price of security guard safety boots? Key Insights for Smart Procurement

- What functions do high-sensitivity flexible pressure sensor (FSR) insoles provide in safety footwear testing? (2024 Guide)

- Why are puncture-resistant soles considered indispensable for scaffolding? Essential Safety for High-Height Construction

- What is the purpose of an anti-slip sole in safety boots? To Prevent Costly Workplace Slips and Falls

- What does OSHA 1910.136 state about safety footwear? A Guide to Compliance & Selection

- What are the key features of safety shoe soles? A Complete Guide to Workplace Foot Protection

- What role do industrial safety shoes play in protecting against asbestos? Essential Guard for Mines & Shipyards

- Why must the design of professional safety footwear balance high-level protection with wearer comfort? Discover the Key