Your first priority when selecting work boots is to match the boot’s protective features directly to the specific hazards of your job. The most critical considerations are always safety compliance, task-specific protection, all-day comfort, and long-term durability. A boot that excels in one environment may be a liability in another.

The central principle of selecting work boots is this: your work environment dictates the boot, not the other way around. The goal is not to find the single "best" boot, but the right boot that mitigates the specific risks you face daily.

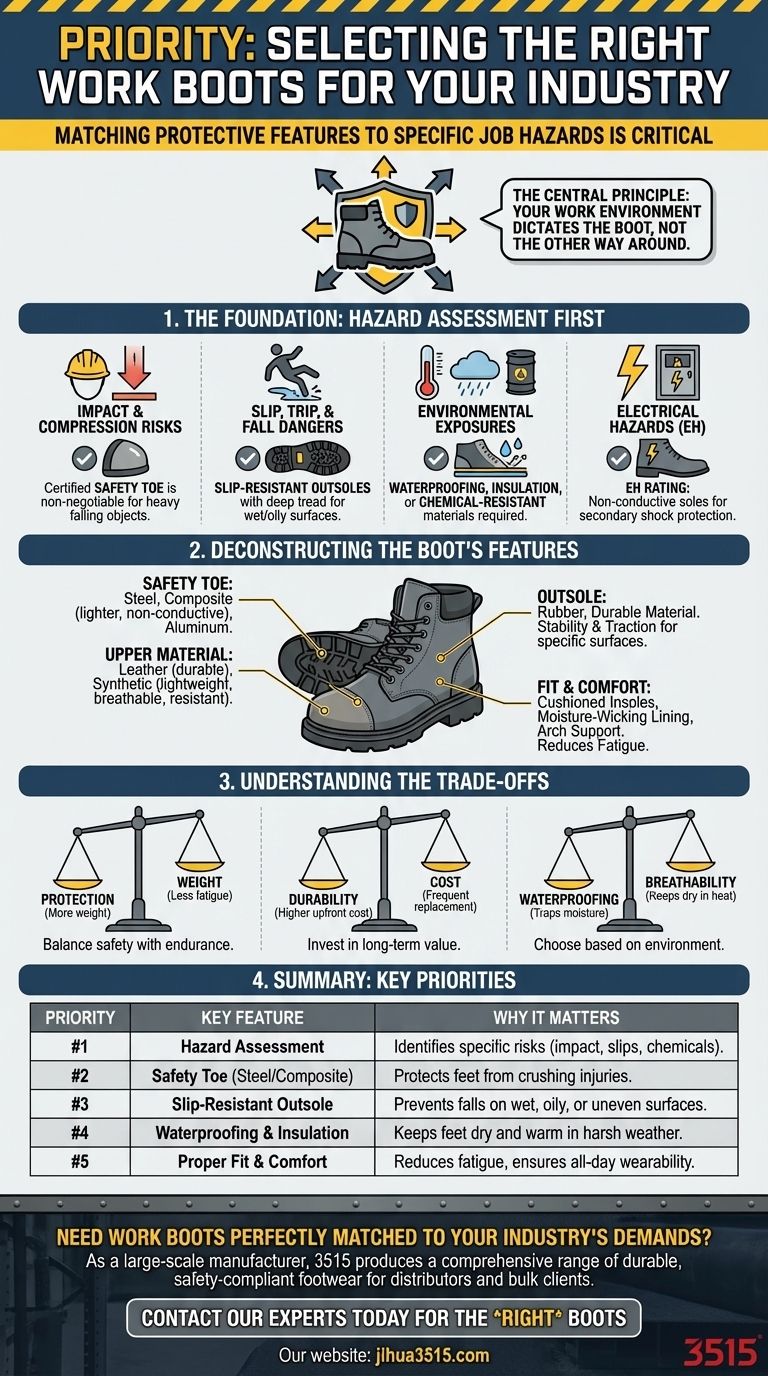

The Foundation: Hazard Assessment First

Before you even look at a boot, you must analyze your workplace. This assessment is the most critical step in making a safe and effective choice.

Identify Impact and Compression Risks

Many jobs, from construction to junk removal, involve the risk of heavy objects falling on or rolling over your feet.

A certified safety toe is non-negotiable in these environments. This is your primary defense against crushing injuries.

Evaluate Slip, Trip, and Fall Dangers

The surface you work on is a major factor. Wet, oily, or uneven ground presents a constant threat.

Look for boots with slip-resistant outsoles. Pay attention to the sole's material (rubber is common) and its tread pattern, which should be deep enough to provide a secure grip.

Consider Environmental Exposures

Your job might expose you to water, extreme temperatures, or harsh substances.

Waterproofing is essential for wet conditions, while insulation is critical in the cold. For workers exposed to chemicals, uppers and soles made from chemical-resistant materials are required to prevent leaks and degradation.

Account for Electrical Hazards

If you work near live electrical circuits, you need specialized protection to prevent shock.

Boots with an Electrical Hazard (EH) rating are designed with non-conductive soles and heels to offer a secondary source of protection.

Deconstructing the Boot's Features

Once you understand your hazards, you can evaluate a boot's components to see if they provide the right solutions.

The Safety Toe: Your First Line of Defense

Safety toes are typically made from steel, composite materials, or aluminum alloy.

Composite toes are a modern choice, offering protection that is lighter than steel and does not conduct heat, cold, or electricity.

The Upper Material: Protection and Breathability

The material of the boot's main body must withstand the abuses of your job.

Leather is a traditional choice known for its durability. Synthetic materials can offer lighter weight, enhanced breathability, or specific resistance to water and chemicals.

The Outsole: Your Connection to the Ground

The outsole determines your stability and traction.

A high-quality outsole will be made of a durable material like rubber and will feature a tread pattern designed to grip the specific surfaces you encounter.

Fit and Comfort: The Key to Endurance

An unsafe boot is one you can't bear to wear. Proper fit is a safety feature, not a luxury.

Your heel should be snug, but you should have enough room to wiggle your toes. Features like cushioned insoles, moisture-wicking lining, and proper arch support reduce fatigue and prevent blisters.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one always involves balancing competing factors.

Protection vs. Weight

More protective features, like thick soles and steel toes, often add weight.

This extra weight can lead to significant fatigue over a long shift. Lightweight options, such as those with composite toes, can be a crucial advantage.

Durability vs. Cost

Investing in a high-quality, durable boot from a reputable brand typically costs more upfront.

However, cheaper boots often wear out quickly, leading to higher replacement costs and potential safety failures over time.

Waterproofing vs. Breathability

A fully waterproof boot is excellent at keeping water out, but it can also trap sweat and moisture inside.

For hot environments or strenuous work, a more breathable (but less waterproof) boot might be necessary to keep your feet dry and comfortable.

Making the Right Choice for Your Job

Your final decision should be guided by a clear understanding of your primary need.

- If your primary focus is protection from heavy objects: Prioritize a certified safety toe (steel or composite) and a durable upper.

- If your primary focus is preventing slips and falls: Scrutinize the outsole for deep treads and an official slip-resistance rating.

- If your primary focus is all-day comfort on your feet: Focus on a proper fit, a lightweight design, and features like cushioned insoles and arch support.

- If your primary focus is working in wet or chemical environments: Insist on guaranteed waterproof construction and materials rated for chemical resistance.

Investing the time to match your boot to your specific hazards is the most critical safety decision you'll make on the job.

Summary Table:

| Priority | Key Feature | Why It Matters |

|---|---|---|

| #1 | Hazard Assessment | Identifies the specific risks (impact, slips, chemicals) you face. |

| #2 | Safety Toe (Steel/Composite) | Protects feet from crushing injuries in construction, etc. |

| #3 | Slip-Resistant Outsole | Prevents falls on wet, oily, or uneven surfaces. |

| #4 | Waterproofing & Insulation | Keeps feet dry and warm in harsh weather conditions. |

| #5 | Proper Fit & Comfort | Reduces fatigue and ensures you wear the boots all day. |

Need work boots that are perfectly matched to your industry's demands?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific hazards you've identified.

Contact our experts today to discuss your requirements and discover how we can provide the right boots for your workforce.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the key features of women's work boots? Secure Protection & True Anatomical Fit

- What are the five most important components of boot fitting? A Guide to Perfect Fit & Performance

- What is Goodyear welt construction in boots? The Secret to Durable, Resoleable Footwear

- What are some key features to look for in pull-on work boots? Prioritize Safety, Fit & Durability

- What is a composite toe work boot? A Lightweight, Non-Metallic Safety Solution

- What are the main benefits of PVC work boots? Lightweight, Waterproof & Affordable Footwear

- How does the outsole of Mortar boots perform in cold and wet conditions? Engineered for Superior Traction & Safety

- What are cowboy boots and what do they represent? A Symbol of Rugged Independence and Style