The primary advantages of PVC work boots are their complete waterproof protection, lightweight construction, and significant affordability compared to other materials. They provide an excellent barrier against moisture and many common chemicals, making them a practical choice for a wide range of wet or messy work environments.

While PVC boots offer an unbeatable combination of waterproof protection and affordability for many applications, the core trade-off is in long-term durability and flexibility when compared to premium materials like rubber.

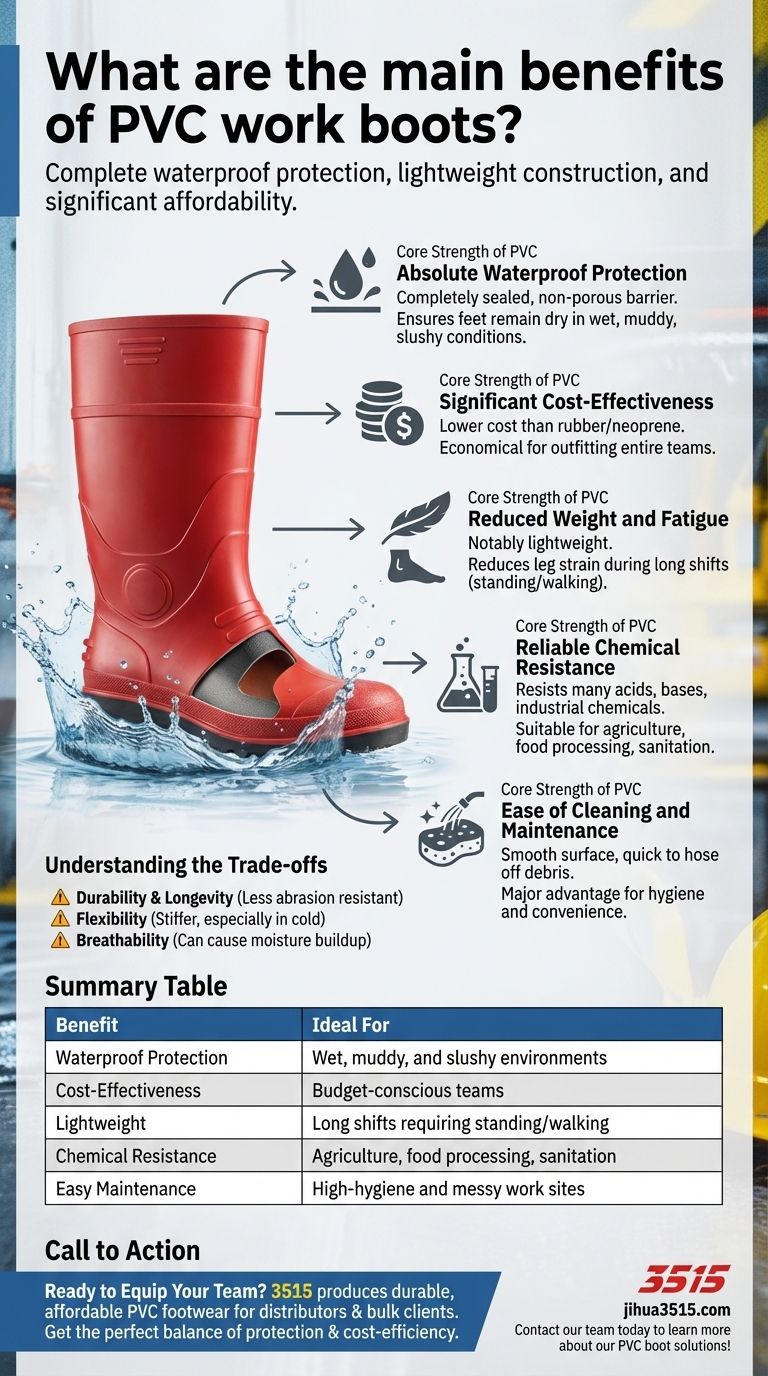

The Core Strengths of PVC

PVC (polyvinyl chloride) is a synthetic polymer valued for several key properties that make it highly suitable for protective footwear.

Absolute Waterproof Protection

Because PVC is a non-porous plastic, boots made from it form a completely sealed barrier. This construction ensures your feet remain dry and comfortable in even the most wet, muddy, or slushy conditions.

Significant Cost-Effectiveness

One of the most compelling benefits of PVC is its low cost. These boots are consistently more affordable than those made from rubber or neoprene, making them an economical choice for individuals and for outfitting entire teams.

Reduced Weight and Fatigue

PVC boots are notably lightweight. This reduces the strain and fatigue on your legs and feet during long shifts, which is a critical factor for jobs that require standing or walking all day.

Reliable Chemical Resistance

PVC offers good resistance to a wide range of substances, including many acids, bases, and common industrial chemicals. This makes it a suitable material for agricultural work, food processing, and certain industrial cleaning applications.

Ease of Cleaning and Maintenance

The smooth, solid surface of PVC makes the boots incredibly easy to clean and sanitize. Debris, mud, and contaminants can be hosed off quickly, which is a major advantage for hygiene and convenience.

Understanding the Trade-offs

To be a trusted advisor, I must be clear about the limitations. The strengths of PVC come with specific compromises you need to understand.

Durability and Longevity

The most significant trade-off is durability. PVC is generally less resistant to abrasion and punctures than high-quality rubber. Over time, it can become brittle and may deteriorate or crack more quickly, especially with heavy, daily use.

Flexibility and Comfort Nuances

While lightweight, PVC is typically stiffer and less flexible than natural rubber. This can become more noticeable in cold weather, and over the boot's lifespan, it may lose some of its original shape and supportive structure.

Breathability

Like any 100% waterproof boot, PVC does not breathe. In hot conditions or during strenuous activity, this can lead to sweat and moisture buildup inside the boot if not paired with appropriate moisture-wicking socks.

How to Apply This to Your Project

Your specific work environment and priorities will determine if PVC is the optimal choice.

- If your primary focus is budget and wet-condition protection: PVC offers an unbeatable value proposition for light-to-moderate duty work or for tasks where boots are not worn daily.

- If your work involves frequent chemical exposure on a budget: The reliable resistance of PVC makes it a strong, economical choice for industries like sanitation, agriculture, or food processing.

- If you need maximum long-term durability and flexibility for heavy use: You will likely be better served by investing in higher-end rubber or neoprene boots, despite their higher initial cost.

Ultimately, choosing the right boot means matching the material's strengths directly to the demands of your job.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Waterproof Protection | Completely sealed, non-porous barrier | Wet, muddy, and slushy environments |

| Cost-Effectiveness | Lower cost than rubber or neoprene | Budget-conscious teams and individuals |

| Lightweight | Reduces leg and foot fatigue | Long shifts requiring standing or walking |

| Chemical Resistance | Resists many acids, bases, and industrial chemicals | Agriculture, food processing, sanitation |

| Easy Maintenance | Smooth surface for quick cleaning and sanitizing | High-hygiene and messy work sites |

Ready to Equip Your Team with High-Value PVC Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and affordable PVC footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the perfect balance of protection, comfort, and cost-efficiency for your specific work environment.

Let's discuss your needs and get a quote for your next order.

Contact our team today to learn more about our PVC boot solutions!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why are work boots considered essential PPE? Unlock Superior Foot Protection for Your Workforce

- Are safety toe boots available in fashionable styles? Discover Modern, Stylish Work Boots

- Are Goodyear welted boots worth it? The Ultimate Guide to Lifelong Footwear

- What are some modern variations of engineer boots? A Guide to Contemporary Styles & Materials

- What is the purpose of integrating an ultrasonic sensor module? Validate Energy Harvesting in Industrial Boots

- What is the historical significance of cowboy boots? From Essential Workwear to Cultural Icon

- How should Western work boots be properly cared for? A 4-Step Guide to Lasting Durability

- What types of jobs are canvas work boots suitable for? Ideal for Light-Duty, High-Mobility Roles