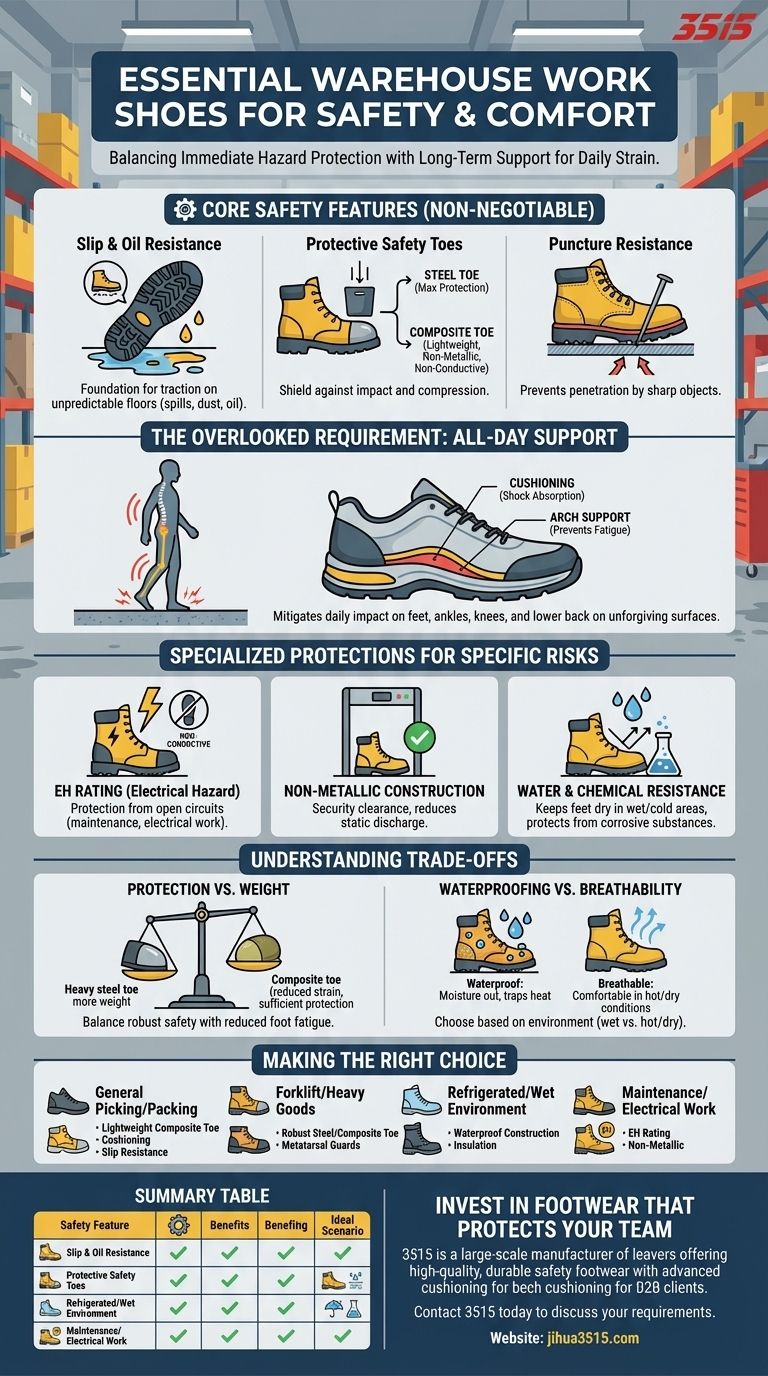

At a minimum, essential warehouse work shoes must include certified slip-resistant outsoles and a protective safety toe (such as steel or composite). Because warehouse work involves long hours on hard concrete floors, they must also feature substantial cushioning and supportive insoles to prevent fatigue and long-term joint or back pain.

The safest warehouse shoe is not just about protection from sudden accidents like falling objects or slips. It's a system that balances immediate hazard protection with the crucial, long-term support needed to mitigate the daily strain of working on hard, unforgiving surfaces.

Core Safety Features for Any Warehouse

Every warehouse presents a baseline of common risks. Your footwear should be equipped to handle these non-negotiable hazards from the moment you step onto the floor.

Slip and Oil Resistance

Warehouse floors can be unpredictable, with surfaces ranging from smooth concrete to areas with spills, dust, or oil. Slip-resistant outsoles are a foundational safety feature, engineered with tread patterns that grip surfaces and channel liquids away to maintain traction.

Protective Safety Toes

The risk of impact from falling objects or compression from rolling carts is constant. Safety toes shield your feet from these dangers.

Steel toes offer maximum protection, while composite toes (made of materials like Kevlar, carbon fiber, or plastic) provide a lightweight, non-metallic alternative that doesn't conduct heat, cold, or electricity.

Puncture Resistance

Warehouse environments can have sharp objects like nails, screws, or metal shards on the floor. A puncture-resistant midsole plate, often made of steel or flexible composite fabric, prevents these items from penetrating the sole of your shoe.

The Overlooked Requirement: All-Day Support

While impact and slip protection are critical, the most common physical complaint from warehouse workers is pain from constant standing and walking on concrete.

The Hazard of Hard Floors

Concrete floors provide zero shock absorption. This daily impact travels up your body, causing fatigue and contributing to chronic pain in your feet, ankles, knees, and lower back.

Cushioning and Arch Support

Excellent cushioning in the midsole absorbs the shock of each step. Equally important are supportive insoles that maintain proper arch support, preventing foot fatigue and conditions like plantar fasciitis. This is not a luxury; it is a critical feature for long-term health.

Specialized Protections for Specific Risks

Beyond the universal requirements, certain warehouse roles or environments demand additional, specialized safety features.

Electrical Hazard (EH) Rating

If you work near live electrical circuits or are part of a maintenance team, you need shoes with an Electrical Hazard (EH) rating. These shoes have non-conductive soles and heels that can protect you from open circuits under dry conditions.

Non-Metallic Construction

For facilities with metal detectors or environments where static electricity is a concern, non-metallic footwear is essential. These shoes use composite toes and non-metal hardware, allowing for easy passage through security and reducing the risk of static discharge.

Water and Chemical Resistance

If your role involves working in wet or refrigerated areas, or around industrial liquids, your footwear needs to be protective. Waterproof materials keep your feet dry to prevent discomfort and health risks, while chemical-resistant materials protect the shoe's integrity from corrosive substances.

Understanding the Trade-offs

Choosing the perfect shoe involves balancing competing features. Understanding these trade-offs is key to making an informed decision.

Protection vs. Weight

Maximum protection often means more weight. A steel toe and steel puncture plate offer robust safety but can increase foot fatigue over a long shift. Lighter composite materials can reduce this strain but may not offer the same level of impact resistance as steel.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for keeping moisture out, but it can also trap sweat and heat inside. In a hot, dry warehouse, a more breathable shoe will be far more comfortable and help prevent skin issues.

Initial Cost vs. Durability

High-quality work shoes with durable construction and superior support systems have a higher upfront cost. However, cheaper alternatives often wear out quickly and provide poor support, leading to higher replacement costs and potential physical pain down the line.

Making the Right Choice for Your Role

Select your footwear based on the most significant risks and demands of your specific job duties.

- If your primary focus is general picking and packing: Prioritize a lightweight composite safety toe, excellent cushioning, and certified slip resistance.

- If your primary focus is operating forklifts or receiving heavy goods: Insist on a robust steel or composite toe and consider adding metatarsal guards for extra protection.

- If your primary focus is working in a refrigerated or wet environment: Choose a shoe with waterproof construction and appropriate insulation to keep your feet warm and dry.

- If your primary focus is maintenance or electrical work: Your shoes must have an Electrical Hazard (EH) rating and should ideally be built with non-metallic components.

Ultimately, choosing the right shoe is an investment in your safety and your ability to perform your job comfortably and effectively.

Summary Table:

| Safety Feature | Key Benefit | Ideal For |

|---|---|---|

| Slip-Resistant Outsole | Prevents slips on slick surfaces | All warehouse environments |

| Safety Toe (Steel/Composite) | Protects from impact & compression | Handling heavy goods, operating machinery |

| Puncture-Resistant Midsole | Shields feet from sharp objects | Areas with debris like nails or screws |

| Cushioning & Arch Support | Reduces fatigue from hard floors | Workers standing/walking for long hours |

| EH Rating / Waterproofing | Protects from electrical hazards or moisture | Maintenance crews, wet/cold environments |

Invest in footwear that protects your team and boosts productivity.

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety footwear designed for the demanding warehouse environment. We combine certified safety features like slip-resistant soles and protective toes with advanced cushioning systems to ensure all-day comfort on hard concrete floors.

Our production capabilities encompass all types of safety shoes and boots, tailored for distributors, brand owners, and bulk clients seeking durable, supportive footwear for their workforce.

Contact 3515 today to discuss your requirements and discover how our reliable footwear solutions can enhance safety and comfort for your team.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Wheat Nubuck Safety Shoes for Bulk Distribution

People Also Ask

- What options are available for restoring worn-out work boots? Expert Strategies for Longevity

- Why are lace-up safety boots recommended over pull-on style boots? Protect High-Risk Feet with Adjustable Support

- Why are waterproof Wellington work boots beneficial? Essential Protection for Wet and Demanding Work Environments

- What are the key considerations for firefighters' boots besides hazard protection? Unlock Peak Performance & Safety

- What should be avoided when storing boots with outsoles? Protect Your Investment from Dry Rot & Decay

- How should Western work boots be maintained for longevity? A 5-Step Guide to Extend Their Life

- How are women's work boots designed differently? Engineered for a Woman's Foot Anatomy

- Why is it worth investing in a high-quality pair of moc toe boots? For Long-Term Value & Durability