To properly store boots and prevent outsole damage, you must avoid environments with extreme temperatures, direct sunlight, excessive moisture, and proximity to ozone-producing sources like electric motors. These factors can cause the materials in the outsole, particularly rubber, to degrade, become brittle, and crack over time.

The core principle of proper boot storage is environmental control. Outsole materials are not inert; they are complex polymers that react to heat, light, moisture, and specific atmospheric chemicals, leading to irreversible damage like cracking and crumbling.

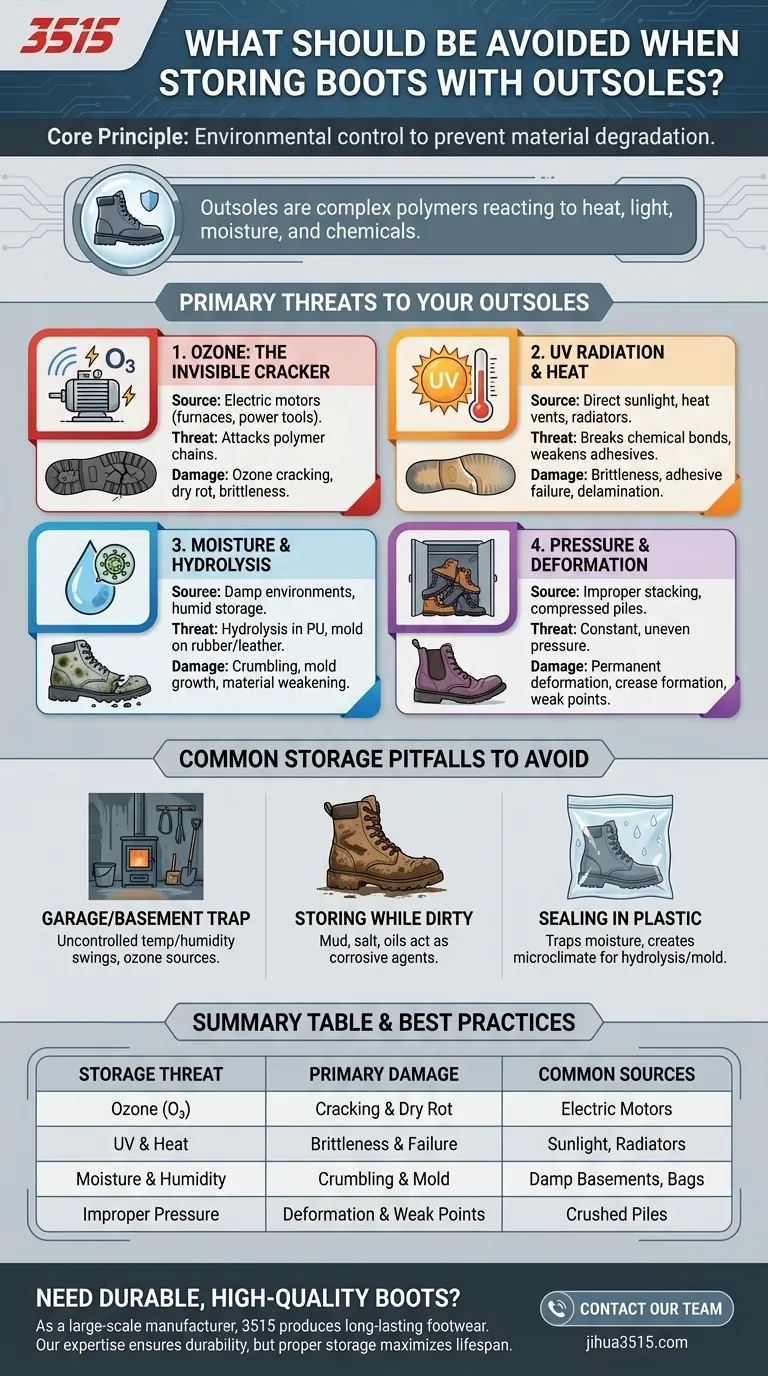

The Primary Threats to Your Outsoles

Understanding what damages boot outsoles requires looking at the invisible environmental factors that break down their chemical structure.

Ozone: The Invisible Cracker

The warning to avoid storing boots near electric motors is scientifically sound and specifically relates to ozone. Many electric motors, especially older ones with brushes, create small sparks during operation that generate ozone gas (O₃).

Ozone is highly reactive and aggressively attacks the polymer chains in rubber and other synthetic outsole materials. This process, known as ozone cracking or dry rot, breaks down the material's flexibility, leading to brittleness and deep cracks even without any physical stress.

UV Radiation and Heat

Direct sunlight is a significant threat. The ultraviolet (UV) radiation in sunlight acts like ozone, breaking the chemical bonds within the outsole's polymers.

High heat, whether from the sun or from being stored near a furnace or heat vent, accelerates these chemical reactions. It can also weaken the adhesives that bond the outsole to the rest of the boot, leading to delamination.

Moisture and Hydrolysis

While boots are made to withstand moisture during use, long-term storage in a damp or humid environment is destructive. For polyurethane (PU) outsoles, this can trigger a chemical reaction called hydrolysis.

Hydrolysis essentially causes the polyurethane to break down and crumble into a dry, crumbly mess. For rubber and leather components, constant dampness promotes the growth of mold and mildew, which can permanently stain and weaken the materials.

Pressure and Deformation

Storing boots improperly, such as in a compressed pile at the bottom of a closet, can cause permanent damage. The constant, uneven pressure can deform the boot's structure and create creases in the outsole that become weak points.

Common Storage Pitfalls to Avoid

Knowing the threats is the first step. The next is recognizing common but damaging storage habits.

The Garage or Basement Trap

Garages and unfinished basements are often the worst places for long-term boot storage. They typically contain furnaces, water heaters, or workshop tools with electric motors that produce ozone.

Furthermore, these areas are rarely climate-controlled, exposing the boots to extreme seasonal swings in temperature and humidity, which accelerates degradation.

Storing Boots While Dirty

Putting boots away immediately after use without cleaning them is a common mistake. Mud, salt, oils, and other chemicals left on the outsole can continue to eat away at the material long after you've taken them off.

Always clean and completely dry your boots before putting them into storage to neutralize these corrosive agents.

Sealing Them in Plastic

It can seem logical to seal boots in a plastic bag or container to protect them from dust. However, this can trap residual moisture from your feet or the environment.

This trapped humidity creates a perfect microclimate for hydrolysis in PU soles and mold growth on other components. If you must cover them, use a breathable cloth bag.

Making the Right Choice for Long-Term Preservation

Your storage strategy should align with your goal for the footwear.

- If your primary focus is maximum longevity for expensive boots: Store them clean and dry in a climate-controlled closet with good air circulation, away from all heat sources and appliances.

- If your primary focus is preventing sole cracking (dry rot): Ensure they are stored far away from any device with an electric motor, such as a furnace, freezer, or power tools.

- If your primary focus is avoiding crumbling PU soles: Your top priority is to avoid any damp or high-humidity environments, like a basement, and never seal them in a non-breathable container.

Ultimately, protecting your investment in quality footwear is achieved by creating a stable, neutral, and clean storage environment.

Summary Table:

| Storage Threat | Primary Damage to Outsoles | Common Sources to Avoid |

|---|---|---|

| Ozone (O₃) | Cracking & Dry Rot (Ozone Cracking) | Electric Motors (Furnaces, Power Tools) |

| UV Radiation & Heat | Brittleness & Adhesive Failure | Direct Sunlight, Heat Vents, Radiators |

| Moisture & Humidity | Crumbling (Hydrolysis in PU) & Mold | Damp Basements, Sealed Plastic Bags |

| Improper Pressure | Permanent Deformation & Weak Points | Being Crushed at Bottom of Closet |

Need Durable, High-Quality Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear designed for longevity. Our expertise in materials science ensures our boots are built to withstand harsh conditions, but proper storage is key to maximizing their lifespan.

We supply distributors, brand owners, and bulk clients with all types of durable shoes and boots. Let us help you provide superior products to your customers.

Contact our team today to discuss your manufacturing needs and how we can deliver value and durability to your supply chain.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is Goodyear Welt Construction and its origin? The Gold Standard for Durable Footwear

- What role does the NFPA play in firefighting boot standards? Ensuring Certified Safety for Every Firefighter

- Why is comfort important in work boots? The Critical Link Between Comfort and Safety

- What should be considered regarding the width of boots? Achieve Ultimate Comfort & Performance

- What kind of boots do Wildland firefighters wear? The Ultimate Guide to NFPA 1977 Certified Footwear

- What are the drawbacks of using bike-specific boots with cleats in cold weather? Stay Warm & Safe

- What should be considered when choosing PVC work boots? Select the Right Boot for Your Job Hazards

- What are the key benefits of Western work boots? Superior Protection, Comfort & Style