When inspecting a non-slip shoe, the sole is your most critical data point. A true non-slip sole is not just about having tread; it's an engineered system. Look for a sole made of soft, flexible rubber with slightly rounded edges and an intricate pattern of small shapes designed to channel liquids away from the point of contact.

The secret to a non-slip shoe isn't a single feature, but a combination of three key elements: a soft rubber material for maximum surface contact, a flexible design that adapts to the floor, and a tread pattern engineered to disperse liquids like water or oil.

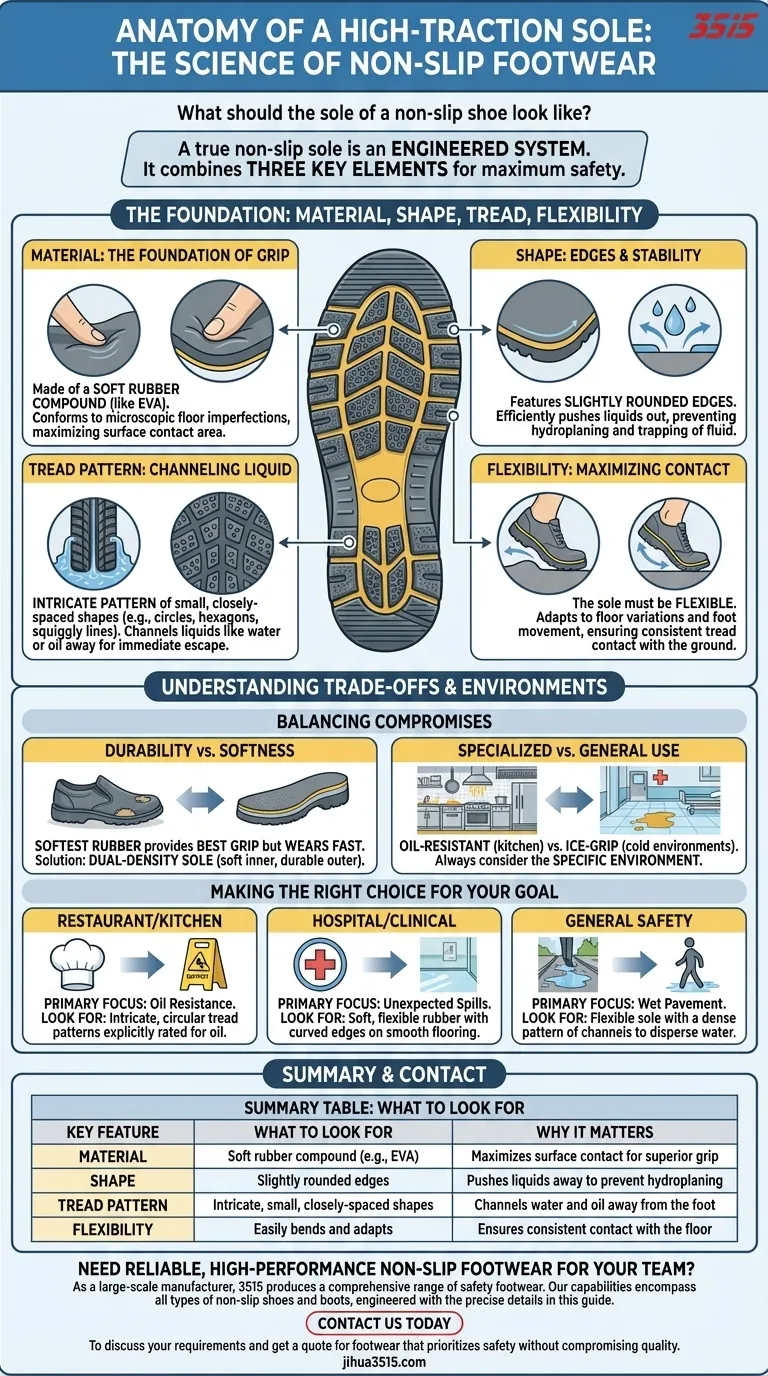

The Anatomy of a High-Traction Sole

To truly identify an effective non-slip shoe, you must understand how its components work together to prevent falls. It's less about a specific look and more about the function behind the design.

Material: The Foundation of Grip

The material is the sole's first line of defense. A high-traction sole will almost always be made of a soft rubber compound, often specified as EVA (ethylene vinyl acetate) rubber.

This softness allows the sole to conform to the microscopic imperfections in a floor surface, maximizing the contact area and therefore the grip.

In contrast, hard, rigid materials like leather are poor choices for slippery environments. They lack the necessary pliability and wear down quickly, losing any effective tread they might have had.

Shape: How Edges Improve Stability

Look at the perimeter of the sole. Effective non-slip designs often feature slightly rounded or curved edges.

This is not an aesthetic choice. This curvature helps to efficiently push water, oil, and other liquids out from underneath the shoe. It prevents the shoe from trapping a layer of liquid, which can cause hydroplaning and a complete loss of traction.

Tread Pattern: The Key to Channeling Liquid

The pattern on the bottom of the sole is arguably the most critical visual indicator. You are not looking for the deep, aggressive lugs of a hiking boot, which are designed for mud and gravel.

For flat, slippery surfaces, you need an intricate pattern of small, closely-spaced shapes. This could be circles, hexagons, or fine squiggly lines.

These small channels work like the tread on a car tire, giving liquids an immediate path to escape from under your foot. A sole with large, flat sections is a major red flag, as it will trap fluid and create a slip hazard.

Flexibility: Maximizing Surface Contact

Finally, the sole should be flexible. A rigid sole can only make contact with the high points of an uneven floor.

A flexible sole, however, can bend and adapt, ensuring that the maximum amount of the tread pattern remains in contact with the ground at all times. This is especially important when walking and shifting your weight.

Understanding the Trade-offs

No single design is perfect for every situation. Being an informed buyer means recognizing the inherent compromises in sole design.

Durability vs. Softness

The softest rubber compounds provide the best grip but also tend to wear down the fastest.

To combat this, some advanced non-slip shoes use a dual-density sole. This features a softer inner layer for cushioning and grip, combined with a more durable outer layer to resist abrasion and extend the life of the shoe.

Specialized vs. General Use

A sole that is certified as "oil-resistant" for a commercial kitchen has a tread pattern and rubber compound specifically designed to handle grease.

This same shoe may not perform as well on ice, which requires a different type of grip. Always consider the specific environment where you will be wearing the shoes.

Making the Right Choice for Your Goal

Ultimately, the best non-slip sole is the one that meets the demands of your environment.

- If your primary focus is a restaurant or kitchen: Look for a sole explicitly rated for oil resistance, with intricate, circular tread patterns.

- If your primary focus is a hospital or clinical setting: Prioritize a soft, flexible rubber sole with curved edges to manage unexpected liquid spills on smooth flooring.

- If your primary focus is general safety on wet pavement: A good all-around choice is a flexible sole with a dense pattern of channels designed to disperse water.

By evaluating the material, shape, and tread pattern, you can move beyond marketing claims and make an informed decision based on sound engineering principles.

Summary Table:

| Key Feature | What to Look For | Why It Matters |

|---|---|---|

| Material | Soft rubber compound (e.g., EVA) | Maximizes surface contact for superior grip |

| Shape | Slightly rounded edges | Pushes liquids away to prevent hydroplaning |

| Tread Pattern | Intricate, small, closely-spaced shapes | Channels water and oil away from the foot |

| Flexibility | Easily bends and adapts | Ensures consistent contact with the floor |

Need reliable, high-performance non-slip footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots, engineered with the precise combination of soft rubber, effective tread patterns, and durable construction detailed in this guide.

Contact us today to discuss your requirements and get a quote for footwear that prioritizes safety without compromising on quality or durability.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What variety of food service shoes are available for different workplace needs? Match Style to Role for Ultimate Safety & Comfort

- How does the comfort of specialized work shoes influence biosecurity compliance? Drive Adherence in Agriculture

- How can you tell if shoes are slip-resistant when shopping online? A Practical Guide to Safety

- How do the structural design features of high-protection work shoes prevent falls? Stability and Gait Secrets Revealed

- Does a rubber sole guarantee a shoe is slip-resistant? Uncover the Truth for Workplace Safety

- What should one look for when purchasing slip resistant footwear that meets ASTM 3445-21? A Guide to True Workplace Safety

- What are slip resistant shoes and how do they work? The Science of Workplace Safety

- What tips should be followed to ensure proper fit and sizing of slip-resistant work shoes? Maximize Safety & Comfort