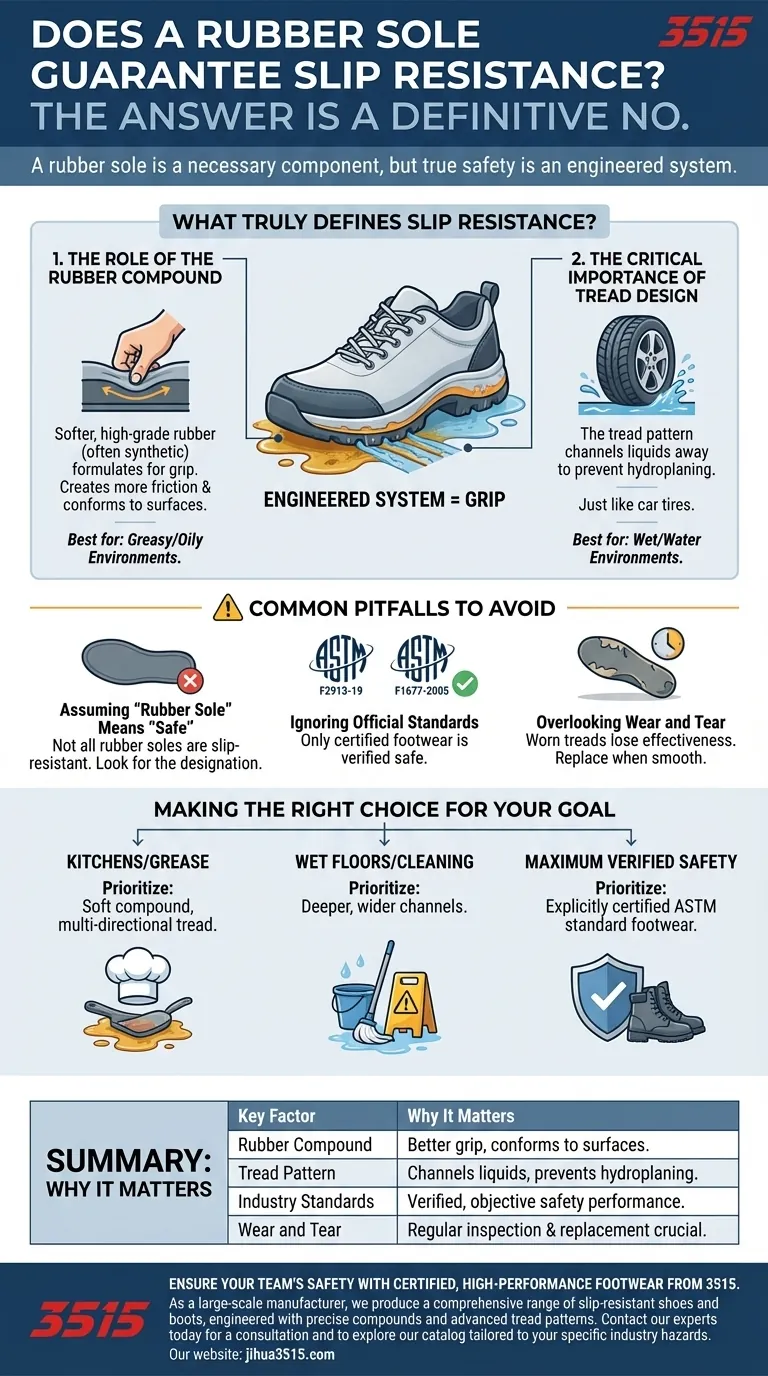

The answer is a definitive no. A rubber sole is a necessary component of a slip-resistant shoe, but its mere presence does not guarantee safety. True slip resistance is an engineered system where the type of rubber, and more importantly, the design of the sole's tread pattern, work together to provide grip on hazardous surfaces.

While all slip-resistant shoes use rubber soles, not all rubber soles are slip-resistant. The critical difference lies in the sole's engineering—specifically, a tread pattern designed to channel away liquids and a rubber compound formulated for grip.

What Truly Defines Slip Resistance?

To understand why "rubber sole" is not enough, you must look at the specific features that prevent slips and falls. A truly slip-resistant shoe is a combination of superior materials and intelligent design.

The Role of the Rubber Compound

Not all rubber is created equal. Slip-resistant shoes use high-grade, often synthetic, rubber compounds specifically formulated to provide a strong grip.

These materials are typically softer, allowing them to create more friction and better conform to microscopic variations in a floor's surface. This is especially effective at gripping greasy or oily surfaces common in professional kitchens and industrial settings.

The Critical Importance of Tread Design

The single most important factor beyond the material itself is the tread pattern. A flat rubber sole can be just as dangerous as a leather one on a wet floor.

The grooves and patterns on a slip-resistant outsole are designed to function like the treads on a car tire. They channel liquids like water and oil away from the point of contact between the shoe and the floor. This action prevents a layer of liquid from building up, a phenomenon known as hydroplaning, which is a primary cause of slips.

How Tread Patterns Work

Effective slip-resistant patterns are typically interlocked and feature many small, sharp edges. These designs increase the sole's surface area and create countless points to "bite" into the walking surface for a secure grip.

The depth and spacing of these grooves are carefully calculated to maximize the shoe's ability to maintain contact with the floor, even when contaminants are present.

Common Pitfalls to Avoid

Relying on simple assumptions about footwear can be a significant safety risk. Understanding these common mistakes is crucial for protecting yourself in hazardous environments.

Assuming "Rubber Sole" Means "Safe"

The most common mistake is equating any rubber-soled shoe with slip resistance. Many casual or dress shoes have smooth rubber soles that offer minimal grip on slick surfaces. Always look for a specific designation of "slip-resistant."

Ignoring Official Standards

For professional environments, the most reliable shoes are those tested against recognized industry standards.

Look for ratings like ASTM F2913-19 or ASTM F1677-2005 (SATRA TM144). Footwear that meets these benchmarks has been objectively proven to provide a high level of traction in controlled test conditions.

Overlooking Wear and Tear

Even the best slip-resistant shoes lose their effectiveness over time. As the tread pattern wears down, the grooves become shallower and can no longer channel away liquids effectively. Regularly inspect your shoes and replace them when the tread becomes smooth.

Making the Right Choice for Your Goal

To select the right footwear, match the shoe's features to the specific hazards you face.

- If your primary focus is working in kitchens or greasy environments: Prioritize shoes made with a soft rubber compound and an intricate, multi-directional tread pattern to grip oily surfaces.

- If your primary focus is navigating wet floors (e.g., healthcare, cleaning): Look for soles with deeper, wider channels designed to effectively displace water and prevent hydroplaning.

- If your primary focus is maximum verified safety: Only purchase footwear that is explicitly certified to meet a recognized ASTM slip-resistance standard.

Understanding these key design elements empowers you to look beyond the material label and make an informed decision for your safety.

Summary Table:

| Key Factor | Why It Matters for Slip Resistance |

|---|---|

| Rubber Compound | Softer, high-grade rubber provides better grip and conforms to surfaces. |

| Tread Pattern | Grooves channel liquids away to prevent hydroplaning and increase surface contact. |

| Industry Standards | Look for ASTM certifications (e.g., F2913-19) for verified, objective safety performance. |

| Wear and Tear | Worn-down treads lose effectiveness; regular inspection and replacement are crucial. |

Ensure your team's safety with certified, high-performance footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, engineered with the precise rubber compounds and advanced tread patterns discussed in this article to meet rigorous standards.

Let us help you mitigate workplace risks. Contact our experts today for a consultation and to explore our catalog tailored to your specific industry hazards.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security