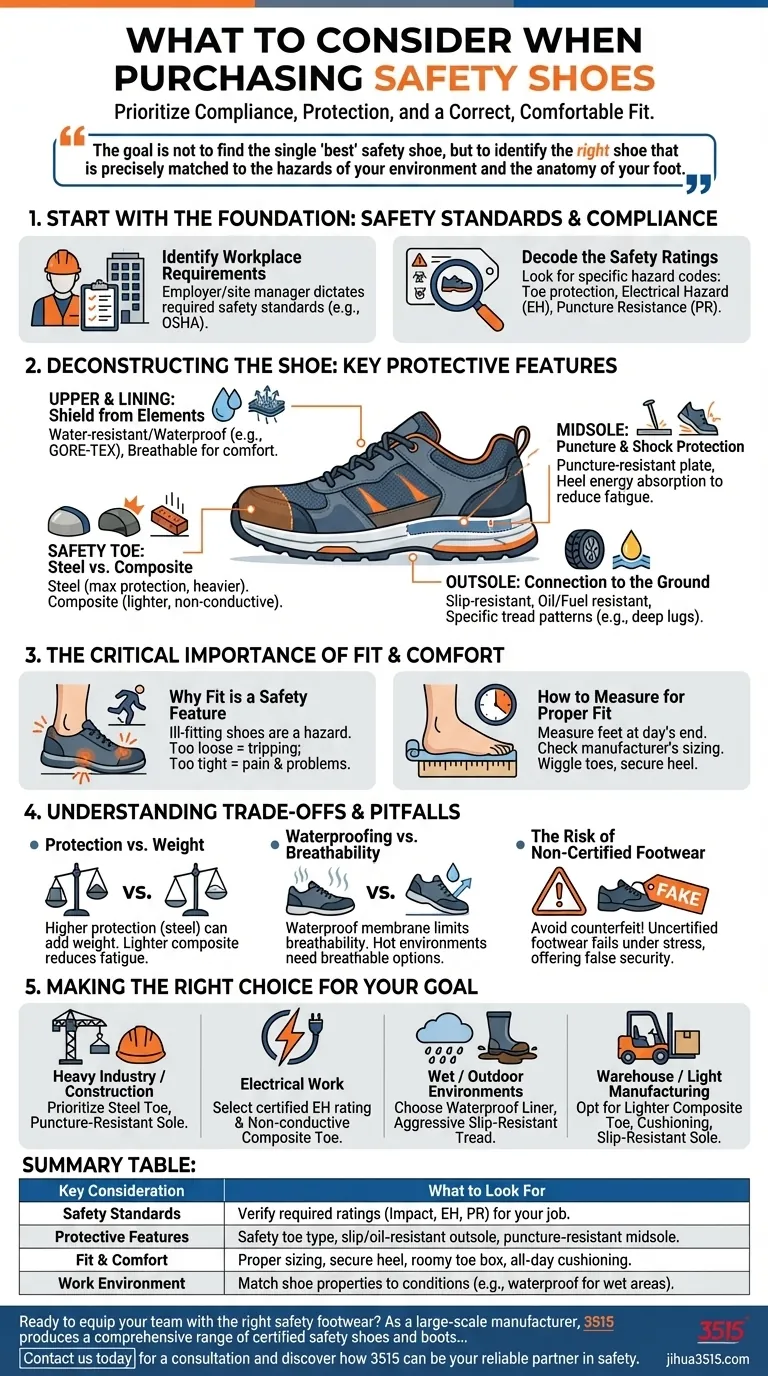

When purchasing safety shoes, you must prioritize three core areas: compliance with your workplace's required safety standards, features that protect against the specific hazards you face, and a correct, comfortable fit for all-day wear. The right choice is a synthesis of these factors, not just a single feature.

The goal is not to find the single "best" safety shoe, but to identify the right shoe that is precisely matched to the hazards of your environment and the anatomy of your foot.

Start with the Foundation: Safety Standards and Compliance

Before evaluating any shoe, you must understand the safety requirements of your job. This is the non-negotiable baseline for your search.

Identify Your Workplace Requirements

Your employer or a site safety manager is the definitive source for the standards your footwear must meet. These standards are often dictated by regulatory bodies like OSHA (Occupational Safety and Health Administration).

They will specify the required level of protection against impact, compression, punctures, or electrical hazards. Starting here narrows your options to only compliant footwear.

Decode the Safety Ratings

Safety shoes are labeled with codes that indicate the specific hazards they protect against. Common ratings include protections for the toe (e.g., impact and compression), electrical hazards (EH), and puncture resistance (PR).

Familiarize yourself with the codes relevant to your industry. This ensures you can quickly verify if a shoe meets your workplace mandates.

Deconstructing the Shoe: Key Protective Features

A safety shoe is a system of components working together. Understanding each part helps you match the shoe's features to your daily tasks.

The Safety Toe: Steel vs. Composite

The reinforced toe cap is the most well-known safety feature. It protects your feet from falling objects and compression.

Steel toes offer maximum protection but can be heavier and conduct temperature. Composite toes, made from materials like carbon fiber or plastic, are lighter and do not conduct heat or electricity, making them ideal for certain environments.

The Outsole: Your Connection to the Ground

The outsole is critical for stability. Look for features that match your work surface.

Key properties include slip resistance for wet or oily floors, oil and fuel resistance to prevent material degradation, and a tread pattern designed for your environment (e.g., deep lugs for loose ground).

The Midsole: Puncture and Shock Protection

The midsole provides underfoot protection. A puncture-resistant plate, often made of steel or flexible composite fabric, prevents sharp objects like nails from piercing the sole.

Many midsoles also feature heel energy absorption, which reduces fatigue and impact stress during long hours of standing or walking on hard surfaces.

The Upper and Lining: Your Shield from the Elements

The upper material determines the shoe's durability, breathability, and resistance to environmental factors.

Look for a water-resistant or waterproof upper, such as one with a GORE-TEX liner, if you work in wet conditions. A breathable upper is crucial for indoor or hot environments to manage moisture and maintain comfort.

The Critical Importance of Fit and Comfort

An ill-fitting safety shoe is not only uncomfortable—it's a safety hazard. Proper fit ensures stability and encourages consistent wear.

Why Fit is a Safety Feature

A shoe that is too loose can cause tripping hazards or a lack of stability. A shoe that is too tight creates painful pressure points, blisters, and long-term foot problems, discouraging you from wearing it at all.

Comfort is not a luxury; it is essential for safety compliance.

How to Measure for a Proper Fit

Always measure your feet before buying, preferably at the end of the day when they are slightly swollen. Compare your measurements to the manufacturer's specific sizing chart, as sizes can vary between brands.

Ensure there is enough room in the toe box to wiggle your toes freely while your heel remains secure without slipping.

Understanding the Trade-offs and Pitfalls

Selecting the right safety shoe involves balancing competing characteristics. Being aware of these trade-offs helps you make a more informed decision.

Protection vs. Weight

Generally, higher levels of protection (like steel toes and puncture plates) can add weight to the shoe. For jobs requiring constant movement, a lighter composite shoe might reduce fatigue, provided it meets the required safety standards.

Waterproofing vs. Breathability

A fully waterproof membrane is excellent for keeping water out, but it can limit the shoe's ability to release sweat and heat. For hot, dry environments, prioritizing a highly breathable, non-waterproof shoe is often the more comfortable choice.

The Risk of Non-Certified Footwear

Always purchase from reputable dealers. Counterfeit or uncertified footwear may look the part but will fail under stress, offering a false sense of security. Guaranteeing authenticity is paramount to ensuring your shoes perform as expected in an accident.

Making the Right Choice for Your Goal

Your specific work environment is the ultimate guide to your selection.

- If your primary focus is heavy industry or construction: Prioritize a steel toe for maximum impact resistance and a puncture-resistant sole.

- If your primary focus is electrical work: You must select a shoe with a certified Electrical Hazard (EH) rating and a non-conductive composite toe.

- If your primary focus is wet or outdoor environments: Choose a shoe with a certified waterproof liner and an aggressive, slip-resistant outsole tread.

- If your primary focus is warehouse or light manufacturing: A lighter composite toe shoe with good cushioning and a slip-resistant sole will provide protection without causing unnecessary fatigue.

Ultimately, investing the time to choose the correct safety footwear is a direct investment in your personal well-being on the job.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Safety Standards | Verify required ratings (e.g., impact, compression, EH, PR) for your job. |

| Protective Features | Safety toe type (steel/composite), slip/oil-resistant outsole, puncture-resistant midsole. |

| Fit & Comfort | Proper sizing, secure heel, roomy toe box, and features for all-day wear (e.g., cushioning). |

| Work Environment | Match shoe properties to your specific conditions (e.g., waterproof for wet areas). |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets the highest standards for protection, durability, and comfort.

Let us help you protect your workforce. Our production capabilities encompass all types of safety footwear tailored to your specific industry hazards.

Contact us today for a consultation and discover how 3515 can be your reliable partner in safety.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Are steel toe boots inherently bad for your feet? Debunking Myths for Workplace Safety

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays