When choosing safety shoes, the single most important step is to conduct a thorough hazard assessment of the specific work environment. This analysis allows you to match identified risks—such as falling objects, slippery surfaces, electrical dangers, or sharp debris—to the certified protective features of the footwear. Factors like material durability, proper fit, and user comfort are also critical for ensuring both safety and daily usability.

The goal is not to find the single "best" safety shoe, but to select the right shoe with the precise protections required for your unique workplace hazards. This begins with understanding the environment, not the footwear catalog.

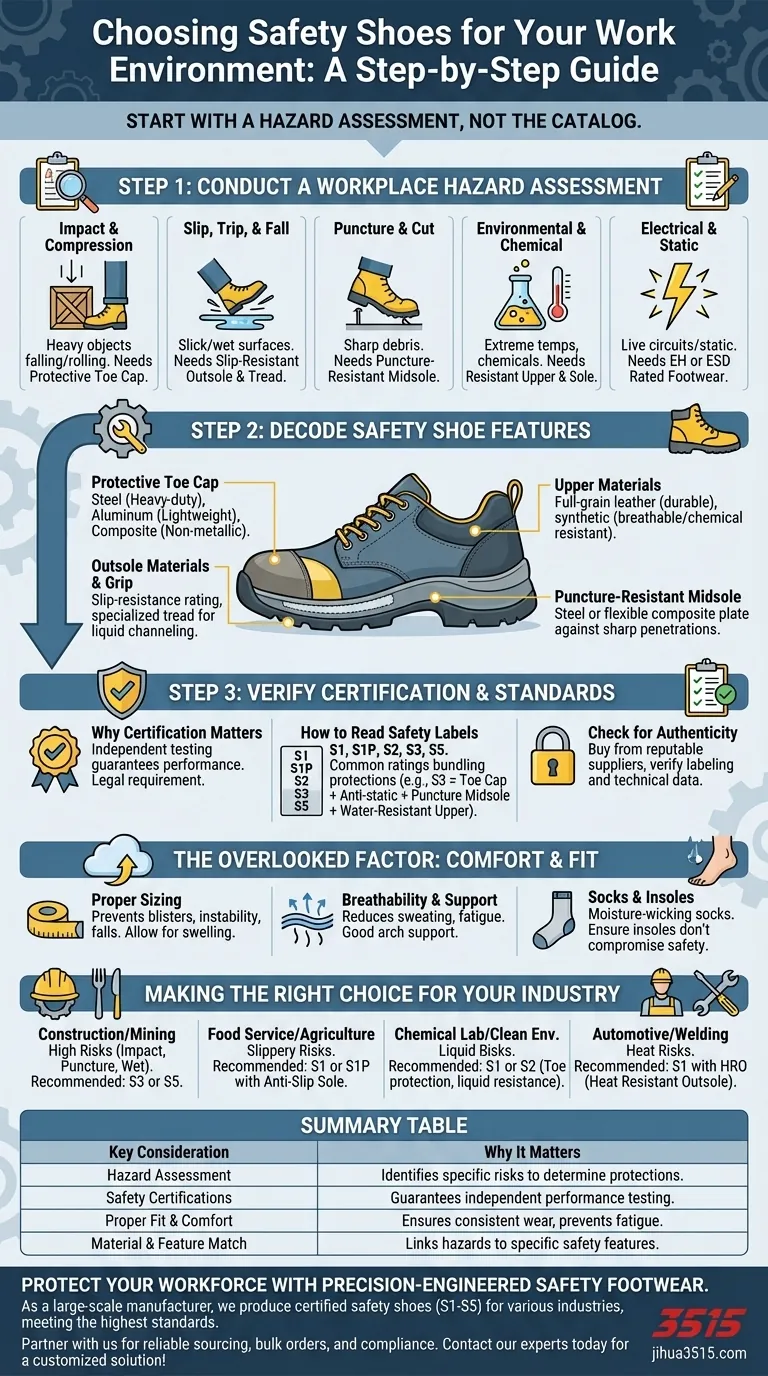

Step 1: Conduct a Workplace Hazard Assessment

Before looking at any shoe, you must first identify the specific dangers your workers face. A clear understanding of the risks is the foundation for making an effective choice.

Identify Impact and Compression Risks

Consider the potential for heavy objects to fall or roll onto the foot. This is a primary concern in construction, warehousing, and manufacturing, dictating the need for a protective toe cap.

Analyze Slip, Trip, and Fall Dangers

Examine all walking surfaces. Are they prone to being wet, oily, or otherwise slick? The sole's material and tread pattern are the most critical features for preventing these common accidents.

Evaluate Puncture and Cut Threats

Scan the environment for sharp objects on the ground, such as nails, scrap metal, or glass. If these are present, a puncture-resistant midsole is a non-negotiable requirement.

Assess Environmental and Chemical Hazards

Determine if workers are exposed to extreme temperatures (hot or cold), water, or chemicals. These conditions require specific upper materials and sole classifications for insulation and resistance.

Consider Electrical and Static Risks

If working near live electrical circuits or in environments sensitive to static discharge, specialized footwear is required. You must distinguish between Electrical Hazard (EH) rated shoes and Electrostatic Dissipative (ESD) footwear.

Step 2: Decode the Features of a Safety Shoe

Once you understand the hazards, you can translate them into specific footwear features.

The Protective Toe Cap

The toe cap is the classic safety feature. It comes in three main materials:

- Steel: The traditional, heavy-duty option.

- Aluminum: Lighter than steel but offers similar protection.

- Composite: Non-metallic, lighter than steel, and does not conduct heat or cold.

Outsole Materials and Grip

The outsole is the shoe's first line of defense against slips. Look for a slip-resistance rating and a tread pattern designed to channel away liquids and provide maximum surface contact.

The Midsole for Puncture Protection

A plate, typically made of steel or a flexible composite fabric like Kevlar, is embedded in the midsole to prevent sharp objects from penetrating the bottom of the shoe.

Upper Materials for Durability and Protection

The shoe's upper protects against splashes, heat, and abrasions. Common materials include full-grain leather for durability and synthetic fabrics for breathability or specialized chemical resistance.

Step 3: Verify Certification and Safety Standards

Professional safety footwear is not just "sturdy"—it is certified to meet specific performance standards.

Why Certification Matters

Certification ensures the shoe has been independently tested to withstand the forces and hazards it claims to protect against. It is your guarantee of performance and is often a legal requirement.

How to Read Safety Labels

Look for markings like S1, S1P, S2, S3, or S5. These are common European ratings that bundle different protections. For example, an S3 rated shoe includes a protective toe cap, anti-static properties, a puncture-resistant midsole, and a water-resistant upper.

Check for Authenticity

Always purchase from reputable suppliers. You can verify a shoe's legitimacy by checking for proper labeling and requesting technical data sheets from the manufacturer to confirm its certified protections.

The Overlooked Factor: Comfort and Fit

An unsafe shoe is one that isn't worn. Discomfort leads to workers removing their footwear or suffering from fatigue, which increases the risk of accidents.

Proper Sizing is a Safety Issue

A shoe that is too loose or too tight can cause blisters, chafing, and instability, leading to trips and falls. Ensure a proper fit that allows for foot swelling throughout the day.

Breathability and Support

Materials that allow moisture to escape prevent sweating and discomfort, which is crucial for long shifts. Good arch support and cushioning reduce fatigue in the feet, legs, and back.

The Role of Socks and Insoles

Wear moisture-wicking socks appropriate for the environment. If using custom or additional insoles, ensure they do not compromise the shoe's fit or its safety features, particularly for ESD-rated footwear.

Making the Right Choice for Your Goal

Match the safety shoe classification directly to the primary risks of your industry.

- If your primary focus is construction or mining: You need S3 or S5 rated footwear for maximum protection against impact, puncture, and wet conditions.

- If your primary focus is food service or agriculture: An S1 or S1P shoe with a high-quality anti-slip sole is often sufficient.

- If your primary focus is a chemical lab or clean environment: S1 or S2 shoes provide essential toe protection and resistance to certain liquids without the heavy-duty features of a construction boot.

- If your primary focus is automotive work or welding: Look for an S1 shoe with an HRO classification, which certifies the outsole is resistant to contact with hot surfaces.

Ultimately, a protected worker is a productive worker, and the right choice in safety footwear is a foundational investment in their well-being.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Hazard Assessment | Identifies specific risks (e.g., falling objects, slippery floors) to determine required protections. |

| Safety Certifications (e.g., S1-S5) | Guarantees the footwear has been independently tested to meet performance standards. |

| Proper Fit & Comfort | Ensures shoes are worn consistently; discomfort can lead to fatigue and accidents. |

| Material & Feature Match | Links hazards to specific features like steel toes, puncture-resistant midsoles, or anti-slip soles. |

Protect Your Workforce with Precision-Engineered Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots tailored to the unique hazards of industries like construction, warehousing, manufacturing, and food processing. We ensure every pair meets the highest standards for impact protection, slip resistance, and durability.

Partner with us to:

- Source Reliably: Get access to a vast catalog of certified (S1-S5) footwear for distributors and brand owners.

- Order in Bulk: Benefit from our large-scale production capabilities for cost-effective bulk orders.

- Ensure Compliance: Provide your workforce with footwear that meets all necessary safety regulations.

Let's equip your team with the right protection. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why is stabilization control essential for UHSS safety shoe toe caps? Key Factors for High-Strength Protection

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts