When choosing injection-molded work boots, your selection process must start with a detailed analysis of your specific work environment and daily activities. The right boot is not just about a single feature, but about a combination of safety, material, and comfort elements that directly counter the hazards and demands of your job.

The most critical mistake is choosing a boot based on a single feature in isolation. Instead, view your work environment as a checklist of problems, and select the injection-molded boot with the precise features designed to solve them.

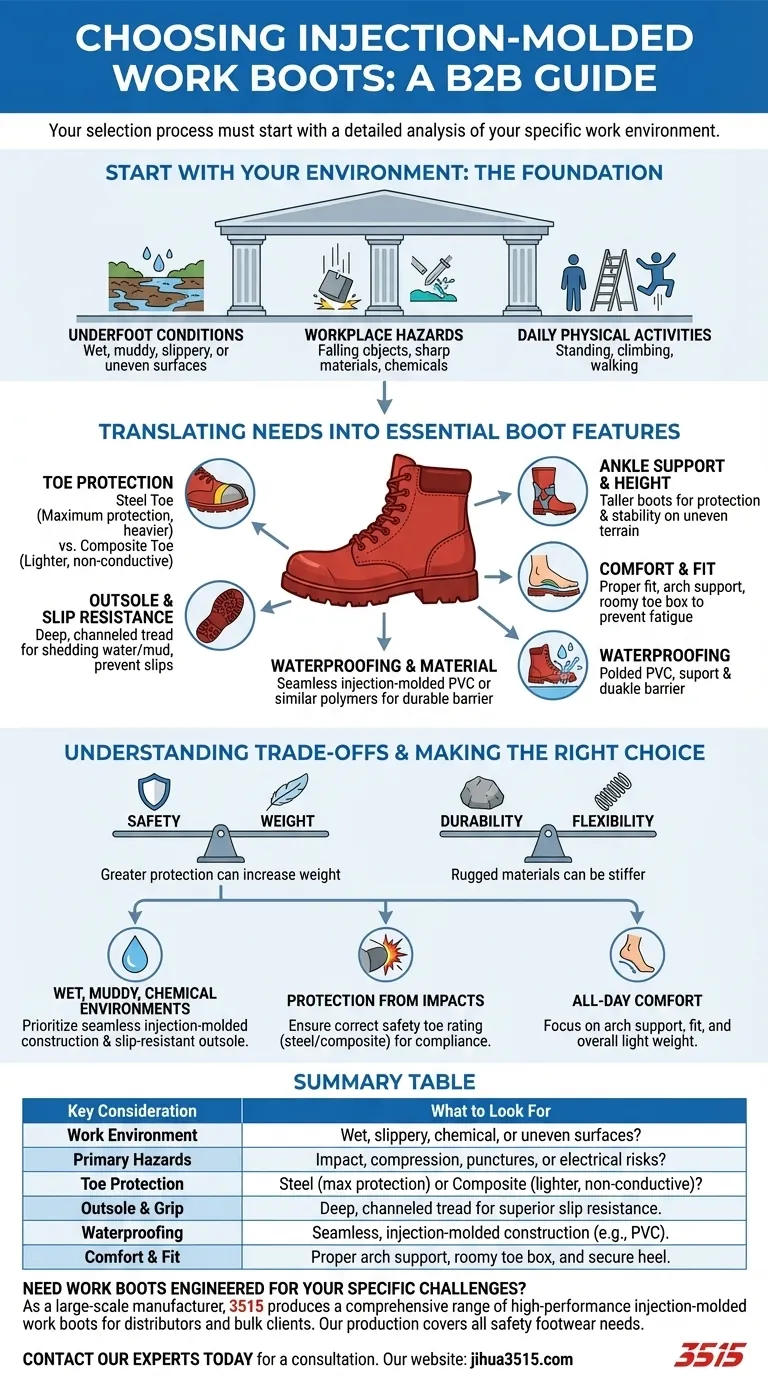

Start with Your Environment: The Foundation of Your Choice

Before looking at any boot, you must first define its mission. The specific conditions of your workplace will dictate every other choice you make.

Analyze Your Underfoot Conditions

The ground beneath your feet presents constant challenges. Consider if you regularly encounter wet, muddy, slippery, or uneven surfaces. The boot's outsole must be matched to these conditions.

Identify Specific Workplace Hazards

Think about the primary risks you face. Are there heavy objects that could fall or roll onto your feet? Do you work around sharp materials? An honest assessment of hazards is non-negotiable.

Consider Your Daily Physical Activities

How you move throughout the day matters. Standing for long hours on concrete, climbing ladders, or jumping in and out of vehicles all place different demands on your feet and require specific types of support and flexibility.

Translating Needs into Essential Boot Features

Once you have a clear picture of your work environment, you can translate those needs into the technical specifications of a boot.

Toe Protection: The First Line of Defense

This is a critical safety feature. Steel toes offer maximum protection but are heavier. Composite toes are lighter, don't conduct cold, and won't set off metal detectors, but can be bulkier.

Outsole and Slip Resistance

The material and tread pattern of the outsole are your primary defense against slips and falls. A deep, channeled tread is crucial for shedding water and mud on slippery surfaces.

Waterproofing and Material

Injection-molded boots, often made from PVC or similar polymers, excel here. The single-piece construction creates a seamless, waterproof barrier that is highly durable and resistant to many chemicals.

Ankle Support and Boot Height

Taller boots offer greater protection for your lower legs from splashes or hazards. They also provide increased ankle support, which is vital when working on uneven terrain.

Comfort and Fit

Proper fit is a safety feature, not a luxury. A poorly fitting boot can cause fatigue, blisters, and distractions that lead to accidents. Ensure there is enough room in the toe box and that your heel does not slip excessively.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one means understanding the inherent compromises.

Safety vs. Weight

Features like steel toes and thick, puncture-resistant soles add significant protection but also increase the boot's weight. This can lead to greater fatigue over a long shift.

Durability vs. Flexibility

The most rugged and chemically resistant materials can sometimes be stiffer, potentially restricting movement. You must balance the need for protection with the need for agility.

Price vs. Longevity

While budget is always a factor, a higher upfront cost often correlates with better materials, superior construction, and enhanced comfort features like arch support, leading to a longer and more effective service life.

Making the Right Choice for Your Job

Use your environmental analysis to guide your final decision.

- If your primary focus is working in wet, muddy, or chemical environments: Prioritize seamless injection-molded construction for its inherent waterproofing and a deep, slip-resistant outsole.

- If your primary focus is protection from impacts and compression: Ensure the boot has the correct safety toe rating (steel or composite) that meets your workplace compliance standards.

- If your primary focus is all-day comfort on hard surfaces: Pay close attention to arch support, overall fit, and the boot's total weight to minimize fatigue.

Investing the time to match your boot to your job is a direct investment in your daily safety and well-being.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Work Environment | Wet, slippery, chemical, or uneven surfaces? |

| Primary Hazards | Impact, compression, punctures, or electrical risks? |

| Toe Protection | Steel toe (maximum protection) or composite toe (lighter, non-conductive)? |

| Outsole & Grip | Deep, channeled tread pattern for superior slip resistance. |

| Waterproofing | Seamless, injection-molded construction (e.g., PVC) for a durable barrier. |

| Comfort & Fit | Proper arch support, roomy toe box, and secure heel to prevent fatigue. |

Need work boots engineered for your specific challenges?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance injection-molded work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, designed to meet the precise demands of any work environment—from superior waterproofing and chemical resistance to impact protection and all-day comfort.

Let us help you equip your team with the right boots for the job. Contact our experts today for a consultation and discover how we can deliver safety and value to your operation.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do subjective norms influence the marketing of work boots and tactical footwear? Leverage Social Identity for Sales

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- Why is checking and cleaning the tread of work boots important? Ensure Safety and Extend Boot Life

- What are the advantages of using PU for work boots? Lightweight Comfort & Durability Explained

- What features make moc toe boots stand out? Discover the Ultimate Comfort & Style

- What specific safety features are required in professional logging boots? Ensure Maximum Protection in Harvesting

- What should warehouse work shoes include for safety? Essential Features for All-Day Protection

- What role do industrial safety shoes and boots play in fire rescue? Pandemic Intervention & PPE Integration Guide