Choosing the right Wellington work boot goes far beyond simple waterproofing. The key safety features to consider fall into three main categories: impact protection for your feet (like steel or composite toe caps), sole integrity for traction and puncture resistance, and specialized ratings for environmental hazards like electricity or chemicals.

The most effective Wellington boot isn't the one with the most features, but the one with the right features. The goal is to conduct a risk assessment of your specific job site and select a boot with protections that directly match those hazards.

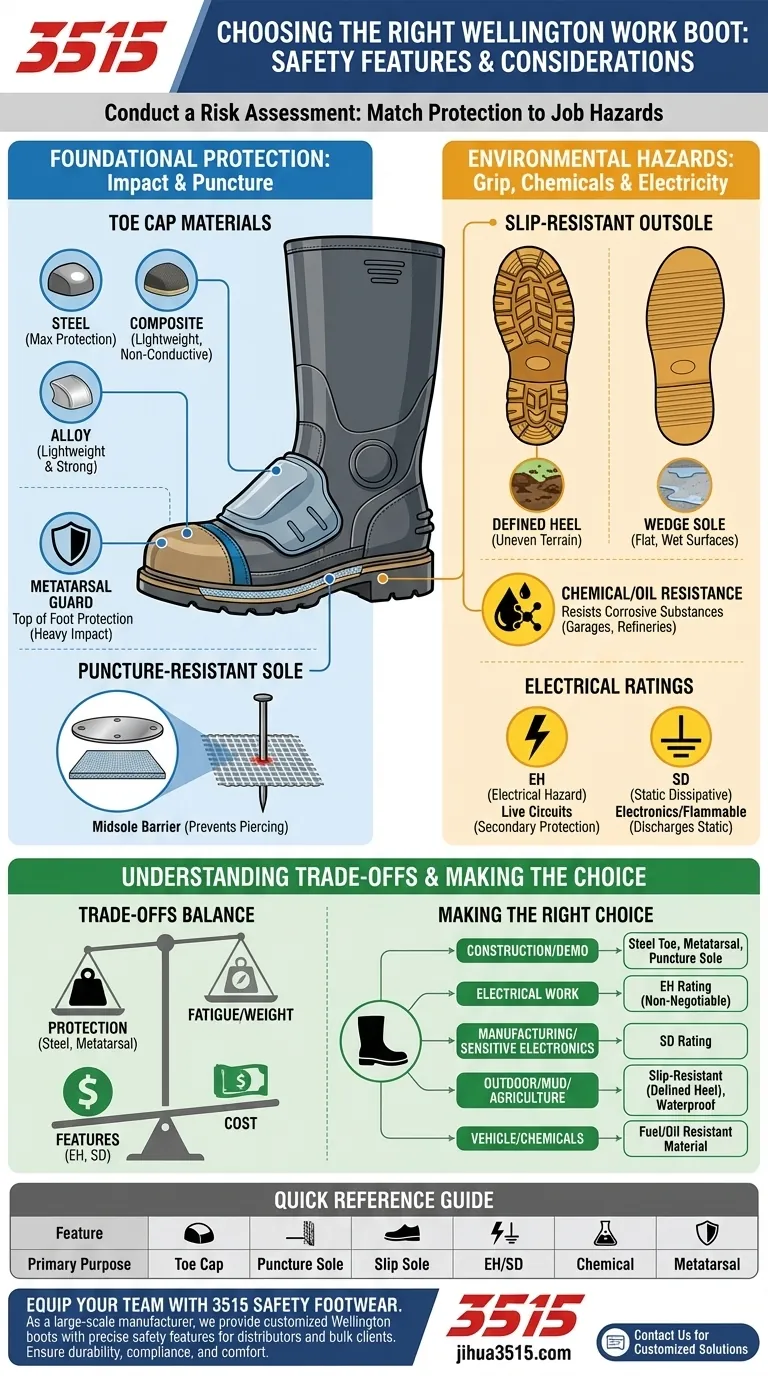

Foundational Protection: Impact and Puncture Resistance

The most common and critical safety features protect your feet from the physical dangers of a worksite. This is the foundation upon which all other features are built.

Protecting Against Falling Objects: The Toe Cap

The primary defense against compression or impact from falling objects is the reinforced safety toe. This is a non-negotiable feature in most hazardous environments and is often required by OSHA.

Understanding Toe Cap Materials

Not all safety toes are the same. Each material offers a different balance of protection, weight, and properties.

- Steel Toes offer the maximum protection against impact and compression. They are the traditional standard but are also the heaviest option.

- Composite Toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, don't conduct electricity, and won't set off metal detectors.

- Alloy Toes are crafted from materials like lightweight aluminum or titanium. They provide comparable protection to steel but at a significantly lower weight.

Beyond the Toes: Metatarsal Guards

For environments with a high risk of heavy falling objects or rolling equipment, a metatarsal guard is crucial. This extra piece of armor sits on top of the boot's instep, protecting the delicate metatarsal bones on the top of your foot.

Underfoot Security: Puncture-Resistant Soles

Sharp objects on a job site, such as nails, screws, and rebar, pose a significant threat. Puncture-resistant plates—often made of steel or flexible woven fabric—are embedded in the midsole to prevent these hazards from piercing the boot.

Environmental Hazards: Grip, Chemicals, and Electricity

Once physical impact is addressed, you must consider the specific environmental conditions you face daily.

The Critical Role of the Outsole

Traction is a paramount safety concern. A slip-resistant outsole, typically made of durable polyurethane or rubber, is designed to grip surfaces and prevent falls, which are one of the leading causes of workplace injuries.

Heel vs. Wedge Soles for Traction

The design of the outsole tread matters. A boot with a defined heel offers superior grip on uneven, soft terrain like mud and dirt. A wedge outsole provides a larger surface area, making it ideal for traction on flat, wet surfaces like concrete or asphalt.

Resistance to Oils and Chemicals

For those working in garages, refineries, or manufacturing plants, exposure to corrosive substances is common. Look for boots made from materials specifically rated to resist breakdown from fuel, oil, and various chemicals.

Electrical Hazard (EH) Rating

If you work near live electrical conductors, an Electrical Hazard (EH) rated boot is essential. These boots are constructed with non-conductive soles and heels to offer a secondary source of protection from electric shock.

Static Dissipative (SD) Rating

In environments with sensitive electronics or flammable materials, static electricity can be a disaster. Static Dissipative (SD) boots are designed to safely discharge static electricity from your body to the ground, preventing sparks and protecting equipment.

Understanding the Trade-offs

Selecting the perfect boot involves balancing competing factors. Understanding these trade-offs is key to making an informed decision.

Protection vs. Weight and Fatigue

Maximum protection often means more weight. Steel toes and metatarsal guards are highly protective but can lead to greater fatigue over a long workday compared to lighter composite or alloy alternatives.

Specialized Features vs. Cost

A boot with a specific rating, like EH or SD, will often cost more than a general-purpose boot. It's crucial to invest in the protections you need without paying for features that are irrelevant to your job's risks.

Durability and Material Choice

Higher-quality materials like premium rubber and polyurethane offer superior lifespan, waterproofing, and chemical resistance. While the initial cost may be higher, they provide more reliable long-term safety and value.

Making the Right Choice for Your Job

Your final decision should be dictated by a clear assessment of your daily tasks and potential risks.

- If your primary focus is construction or demolition: Prioritize steel toe caps, metatarsal guards, and puncture-resistant soles for maximum impact protection.

- If your primary focus is electrical work: An Electrical Hazard (EH) rating is non-negotiable to protect against accidental contact with live circuits.

- If your primary focus is manufacturing with sensitive electronics: Look for Static Dissipative (SD) boots to prevent damage to components.

- If your primary focus is outdoor work in mud or agriculture: Emphasize aggressive, slip-resistant outsoles with a defined heel and superior waterproofing.

- If your primary focus is working around vehicles or chemicals: Ensure the boot material is certified as fuel and oil-resistant.

By aligning these specific safety features with your unique work environment, you transform your boots from simple footwear into essential personal protective equipment.

Summary Table:

| Safety Feature | Purpose | Key Considerations |

|---|---|---|

| Safety Toe Cap | Protects against impact/compression | Steel (max protection), Composite (lightweight, non-conductive), Alloy (lightweight, strong) |

| Puncture-Resistant Sole | Prevents sharp objects from piercing boot | Steel or woven fabric plate in midsole |

| Slip-Resistant Outsole | Reduces fall risk on wet/slippery surfaces | Defined heel for uneven terrain, wedge sole for flat surfaces |

| EH/SD Ratings | Protects against electrical hazards/static discharge | EH for live circuits, SD for electronics/flammable areas |

| Chemical/Oil Resistance | Prevents material breakdown from corrosive substances | Essential for garages, refineries, manufacturing |

| Metatarsal Guard | Shields top of foot from heavy falling/rolling objects | Critical for high-risk environments like demolition |

Ready to equip your team with the right Wellington work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, including Wellington boots with the precise safety features your job demands—from steel toes and puncture-resistant soles to EH/SD ratings and chemical resistance.

We ensure durability, compliance, and comfort to keep your workforce protected and productive. Contact us today for a customized solution that matches your specific hazards and requirements.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How does the flexibility design of industrial safety shoes assist shipyard electricians? Boost Agility & Back Health

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team