At its core, the welt is the architectural linchpin of high-quality shoe construction. It is a strip of leather that runs along the perimeter of the outsole, serving as the crucial connection point between the shoe's upper and its sole. This construction method is not merely for aesthetics; its primary functions are to provide a durable attachment, enhance water resistance, and allow the shoe to be resoled multiple times.

The presence of a welt fundamentally changes a shoe from a disposable item into a durable, repairable asset. It is the key component that enables longevity and a custom fit that develops over time.

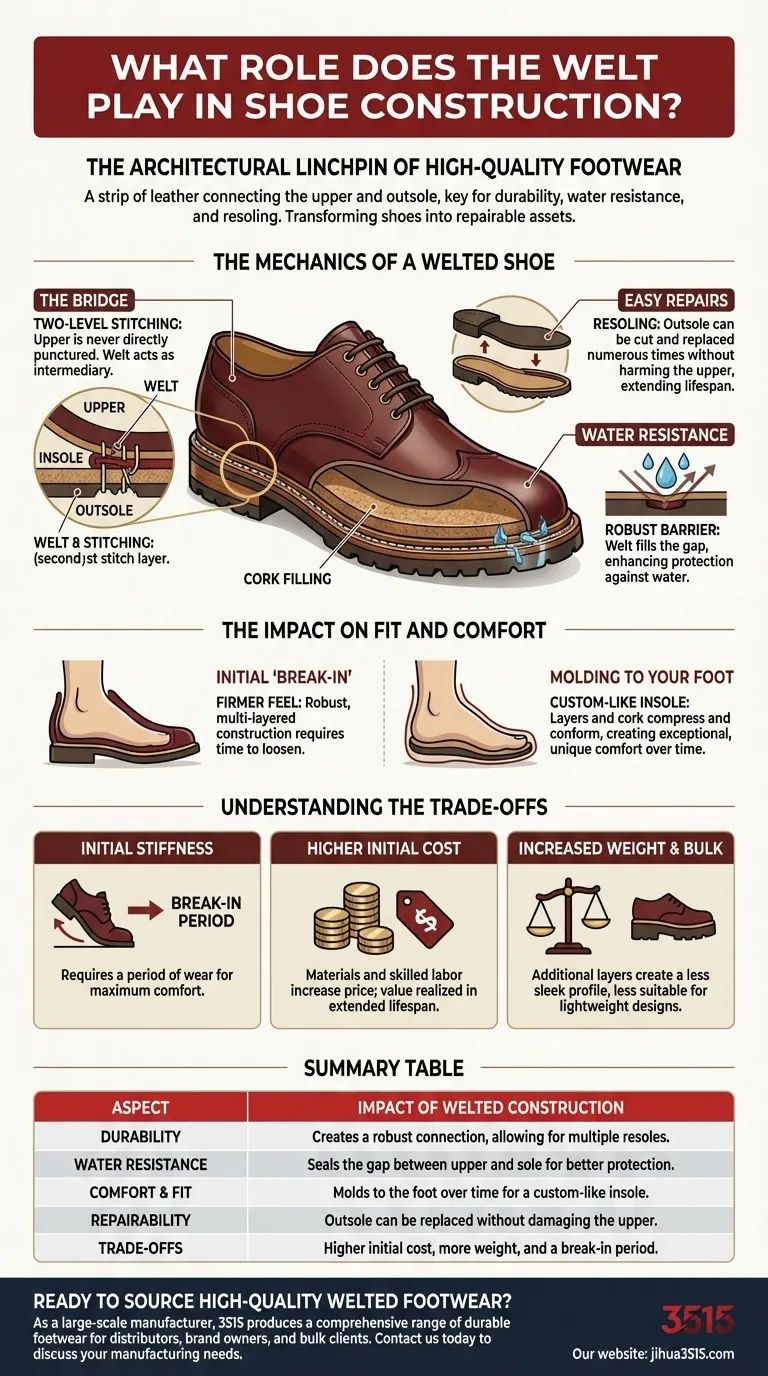

The Mechanics of a Welted Shoe

A welted shoe, most famously the Goodyear welt, is built differently from a shoe where the sole is simply glued on. This structural difference is the source of its unique benefits.

The Bridge Between Upper and Outsole

The welt acts as an intermediary. First, the upper part of the shoe and the insole are stitched to the welt. Then, in a separate process, the welt is stitched to the outsole.

This two-level stitching system means the upper is never directly punctured by the stitches that hold the sole on.

A Foundation for Easy Repairs

The most significant advantage of a welt is resoling. When the outsole wears out, a cobbler can simply cut the stitches connecting the outsole to the welt and attach a new one.

This process can be repeated numerous times without compromising the shoe's upper, dramatically extending its lifespan.

Enhancing Water Resistance

The welt fills the gap between the sole and the upper. This creates a more robust physical barrier against water seeping into the shoe from the sides, offering superior protection compared to simpler construction methods.

The Impact on Fit and Comfort

Welted construction has a distinct feel on the foot, which evolves significantly with wear.

The Initial "Break-in" Period

Goodyear welted shoes are known for having a firmer, more rigid feel when they are new. This is a direct result of their robust, multi-layered construction.

Molding to Your Foot

Over time, the layers of leather and the typical cork filling within a welted shoe compress and conform to the unique shape of your foot.

This process creates a custom-like insole, resulting in exceptional comfort and support that is unique to the wearer.

Understanding the Trade-offs

While highly regarded, welted construction is not the ideal choice for every situation. Understanding its inherent compromises is key to making an informed decision.

Initial Stiffness

The break-in period is a real consideration. Unlike a sneaker or a cemented shoe that feels flexible immediately, a welted shoe requires a period of wear to achieve maximum comfort.

Higher Initial Cost

The materials and skilled labor required for welted construction make these shoes more expensive upfront. The value is realized over the product's extended lifespan, not in its initial price tag.

Increased Weight and Bulk

The additional layers of leather, stitching, and cork add weight and create a less sleek profile compared to glued (cemented) constructions. This makes them less suitable for lightweight, athletic, or minimalist footwear designs.

Making the Right Choice for Your Goal

Ultimately, the right shoe construction depends entirely on your priorities.

- If your primary focus is longevity and repairability: A welted shoe is the definitive choice, as it is engineered to be rebuilt and last for decades.

- If your primary focus is value over the long term: The higher initial cost of a welted shoe is often justified by its extended lifespan and the ability to replace the sole for a fraction of the cost of a new pair.

- If your primary focus is immediate flexibility and low weight: A non-welted, cemented construction might be more suitable, but you must accept the trade-off in durability and repair options.

Understanding the role of the welt empowers you to look beyond style and choose footwear based on its fundamental quality and engineering.

Summary Table:

| Aspect | Impact of Welted Construction |

|---|---|

| Durability | Creates a robust connection, allowing for multiple resoles |

| Water Resistance | Seals the gap between upper and sole for better protection |

| Comfort & Fit | Molds to the foot over time for a custom-like insole |

| Repairability | Outsole can be replaced without damaging the upper |

| Trade-offs | Higher initial cost, more weight, and a break-in period |

Ready to Source High-Quality Welted Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of welted shoes and boots, designed for longevity and superior performance.

Contact us today to discuss your manufacturing needs and discover how we can bring value and quality to your product line.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team