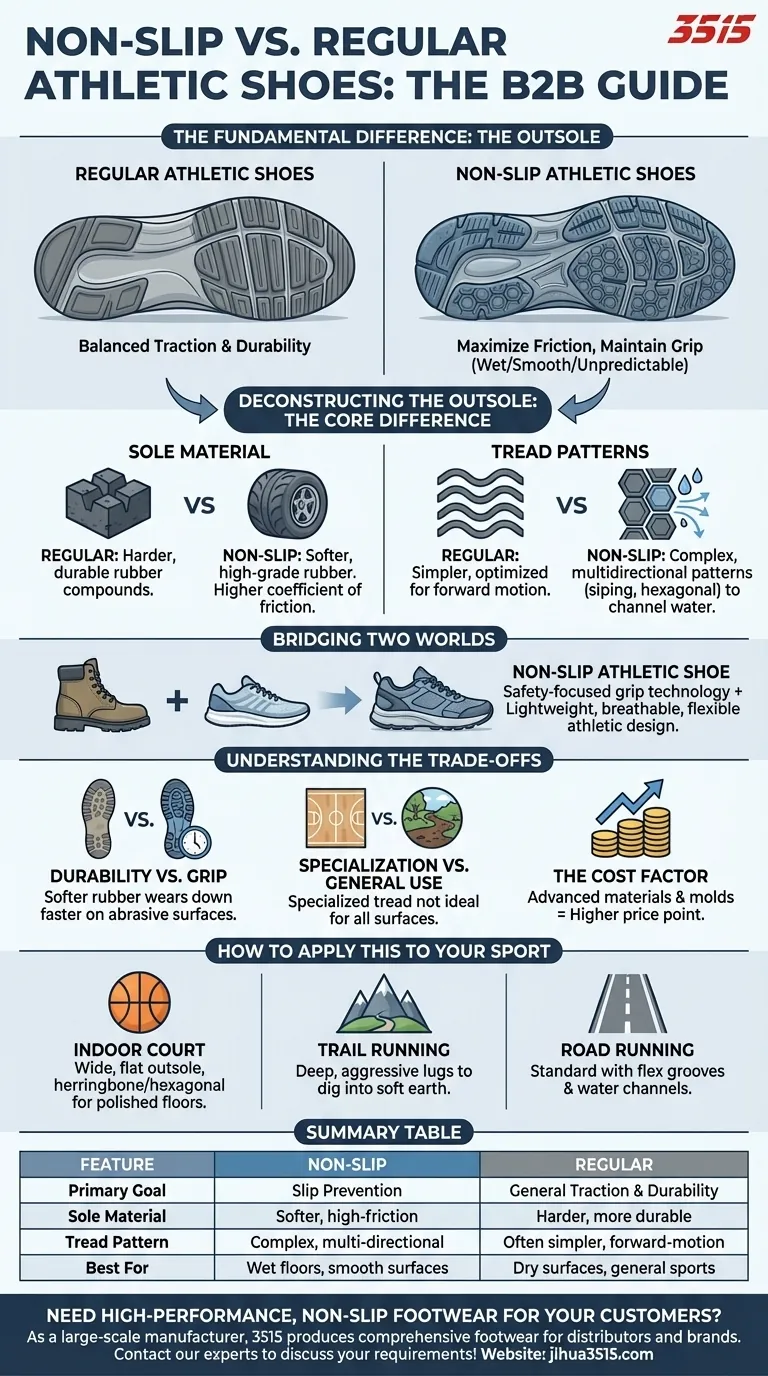

The fundamental difference between non-slip athletic shoes and regular athletic shoes lies entirely in the outsole. Non-slip versions feature specialized sole materials and intricate, multi-directional tread patterns explicitly engineered to maximize friction and maintain grip on wet, smooth, or unpredictable surfaces.

While all athletic shoes are designed for traction, "non-slip" athletic shoes borrow engineering principles from occupational safety footwear to provide superior grip, particularly in environments where slipping is a primary concern.

Deconstructing the Outsole: The Core Difference

The outsole is where the technology of grip truly lives. A shoe's ability to prevent a slip is determined by the interplay between its sole material and tread design.

The Role of Sole Material

Regular athletic shoes use a variety of rubber compounds balanced for durability and traction. Non-slip shoes prioritize traction above all.

They often use a softer, higher-grade rubber compound. Softer rubber has a higher coefficient of friction, meaning it can "stick" to surfaces more effectively, much like the tires on a race car.

The Science of Tread Patterns

This is the most visible distinction. The pattern on the bottom of the shoe is engineered to channel away water and increase surface contact.

Non-slip shoes feature complex, multidirectional tread patterns, often with small, intricate grooves (siping) and hexagonal shapes. This design ensures that no matter the angle of your foot, some part of the tread is positioned to provide grip and push liquid out from under the shoe. A regular shoe may have a simpler pattern optimized only for forward motion.

Bridging Two Worlds: Athletics and Safety

The term "non-slip" is most common in the world of work and safety shoes designed for kitchens or industrial settings.

Non-slip athletic shoes apply this same safety-focused grip technology to a lightweight, breathable, and flexible athletic design. They offer the slip-resistance of a work shoe but are built for the performance demands of sports.

Understanding the Trade-offs

Choosing a shoe with enhanced slip resistance involves considering a few key compromises. It's not always the best choice for every situation.

Durability vs. Grip

The primary trade-off is durability. The softer rubber compounds that provide excellent grip also tend to wear down faster than the harder rubber found on many standard shoes, especially on abrasive surfaces like asphalt or concrete.

Specialization vs. General Use

A highly specialized non-slip tread may not be ideal for all activities. For example, the deep lugs on a trail shoe can feel unstable on a smooth gym floor, while the flat, sticky sole of a court shoe would be useless on a muddy path.

The Cost Factor

The advanced rubber compounds and more complex mold designs required for superior non-slip outsoles often result in a higher price point compared to standard models.

How to Apply This to Your Sport

Your choice should be dictated by the surface and the type of movement your activity requires. The term "non-slip" is less important than finding the right type of traction.

- If your primary focus is indoor court sports (basketball, volleyball, tennis): Look for shoes with a wide, relatively flat outsole and a herringbone or hexagonal pattern to maximize surface contact on polished floors.

- If your primary focus is trail running or outdoor activities: Seek out shoes with deep, aggressive, and widely-spaced lugs that can dig into soft earth and shed mud.

- If your primary focus is road running or general fitness: A standard athletic shoe is usually sufficient, but prioritize models with ample flex grooves and a tread pattern designed to channel water on wet pavement.

Ultimately, selecting the right shoe means matching its specific traction technology to the demands of your chosen activity.

Summary Table:

| Feature | Non-Slip Athletic Shoes | Regular Athletic Shoes |

|---|---|---|

| Primary Goal | Slip Prevention | General Traction & Durability |

| Sole Material | Softer, high-friction rubber | Harder, more durable rubber |

| Tread Pattern | Complex, multi-directional | Often simpler, optimized for forward motion |

| Best For | Wet floors, smooth surfaces, unpredictable terrain | Dry surfaces, general sports, road running |

Need High-Performance, Non-Slip Footwear for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced non-slip athletic models.

We can help you source or develop the perfect athletic footwear with specialized grip technology tailored to your market's needs.

Contact our experts today to discuss your requirements and get a competitive quote!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- What materials are best for athletic activities in warm climates? Stay Cool with Moisture-Wicking Fabrics