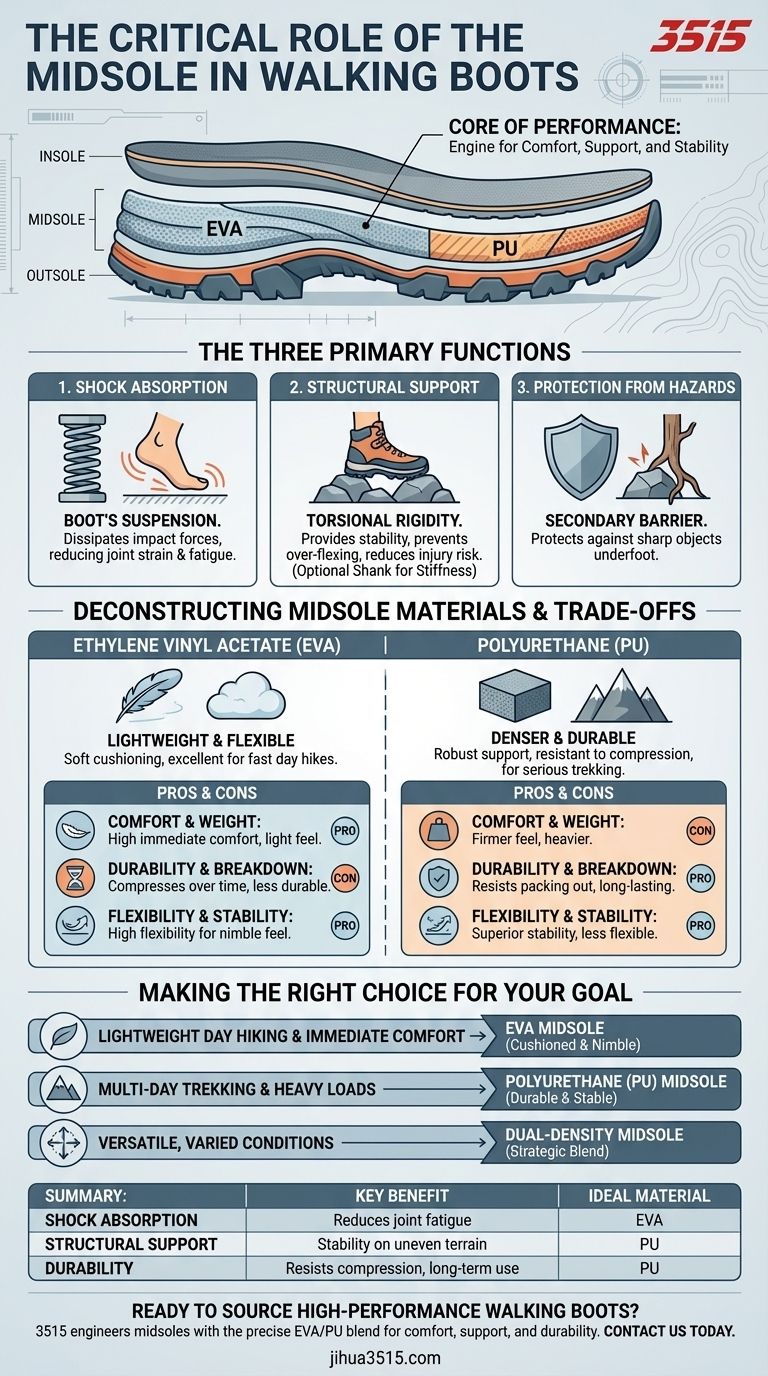

At the core of every walking boot's performance, the midsole serves as the critical engine for comfort and support. This layer, positioned between the insole your foot rests on and the outsole that touches the ground, is responsible for shock absorption, providing structural stability, and determining the boot's overall stiffness.

The midsole is the single most important component defining a boot's feel and function. Understanding its material—typically EVA or Polyurethane—is the key to matching the boot to its intended purpose, from casual walks to demanding treks.

The Three Primary Functions of a Midsole

A well-engineered midsole is not just a simple layer of padding. It performs several distinct jobs that directly impact your joints, energy levels, and safety on the trail.

1. Shock Absorption

The midsole's primary role is to act as the boot's suspension system. With every step, it compresses to absorb impact, dissipating forces that would otherwise travel up into your ankles, knees, and hips.

This cushioning is crucial for reducing fatigue and preventing joint strain, especially during long hikes or when walking on hard, unforgiving surfaces.

2. Structural Support and Stiffness

The midsole dictates the torsional rigidity of the boot—how much it resists twisting. A firmer midsole provides a stable platform on uneven, rocky terrain.

This stability prevents your foot from over-flexing on difficult ground, which reduces muscle strain and the risk of injury. Some boots embed a rigid plate called a shank within the midsole for even greater stiffness and underfoot support.

3. Protection from Hazards

While the outsole provides the first line of defense, the dense midsole material offers a secondary barrier. It helps protect the bottom of your foot from sharp rocks, roots, and other objects you might step on.

Deconstructing Midsole Materials

The material used in a midsole is the most significant factor in its performance. The choice between the two most common options creates a distinct difference in how a boot feels and lasts.

Ethylene Vinyl Acetate (EVA)

EVA is a lightweight foam that offers excellent cushioning and flexibility. It feels soft and comfortable right out of the box, making it a popular choice for lighter hiking boots and trail shoes.

Think of it as the material found in most high-performance running shoes. It provides a cushioned, energetic feel.

Polyurethane (PU)

Polyurethane is a denser, firmer, and significantly more durable material than EVA. It provides robust, long-lasting support and is highly resistant to compression.

Boots designed for serious backpacking or mountaineering almost always use PU midsoles because they can withstand the abuse of heavy loads and rugged terrain for years.

Understanding the Trade-offs: EVA vs. Polyurethane

Choosing between midsole materials involves a direct trade-off between immediate comfort and long-term durability. Neither is universally "better," but one will be better for your specific needs.

Comfort vs. Weight

EVA is lighter and provides a softer, more "bouncy" feel. This often translates to greater initial comfort on less demanding terrain. PU is heavier and feels firmer underfoot.

Durability vs. Breakdown

PU is the clear winner for longevity. It resists "packing out" or permanent compression. An EVA midsole, by contrast, will gradually lose its cushioning and shock-absorbing ability over time as the foam cells break down.

Flexibility vs. Stability

EVA's flexibility is excellent for fast-and-light day hikes. However, the superior density and firmness of PU provide unmatched stability, which is critical when carrying a heavy pack or navigating challenging, off-camber trails.

Making the Right Choice for Your Goal

Selecting the right boot begins with understanding how its midsole aligns with your activity.

- If your primary focus is lightweight day hiking and immediate comfort: Choose boots with an EVA midsole for excellent cushioning and a nimble feel.

- If your primary focus is multi-day trekking or carrying heavy loads: Opt for a Polyurethane (PU) midsole for its non-negotiable durability and superior stability.

- If you need a versatile boot for varied conditions: Consider a dual-density midsole that strategically combines the lightweight cushioning of EVA with the robust support of PU.

Ultimately, understanding the midsole empowers you to choose a boot based on its underlying engineering, ensuring it will perform exactly as you need it to on the trail.

Summary Table:

| Function | Key Benefit | Ideal Material |

|---|---|---|

| Shock Absorption | Reduces joint fatigue on hard surfaces | EVA |

| Structural Support | Provides stability on uneven terrain | Polyurethane (PU) |

| Durability | Resists compression for long-term use | Polyurethane (PU) |

Ready to source high-performance walking boots with the perfect midsole for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to engineer midsoles with the precise blend of EVA and PU to meet your customers' needs for comfort, support, and durability.

Contact us today to discuss your specific requirements and leverage our expertise to build a superior product line.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What are the advantages of short walking boots? Lightweight Support for Foot & Ankle Recovery

- What are yard boots used for? Your Go-To Footwear for Stable & Farm Versatility

- How does overheating affect winter boot performance? Avoid the Sweat-to-Freeze Cycle

- What materials are commonly used in bite-proof leather boots? A Guide to Multi-Layer Protective Footwear

- What types of snow boots are available based on different needs? Choose the Right Boot for Your Winter Activity

- Why are high-specification boots necessary for populations at high risk of falling? Elevate Safety and Mobility

- What technical features are required in outdoor boots for rural roads? Ensure Safety on Uneven Terrain

- What are the risks of using worn-out walking shoes? Prevent Injury and Protect Your Mobility