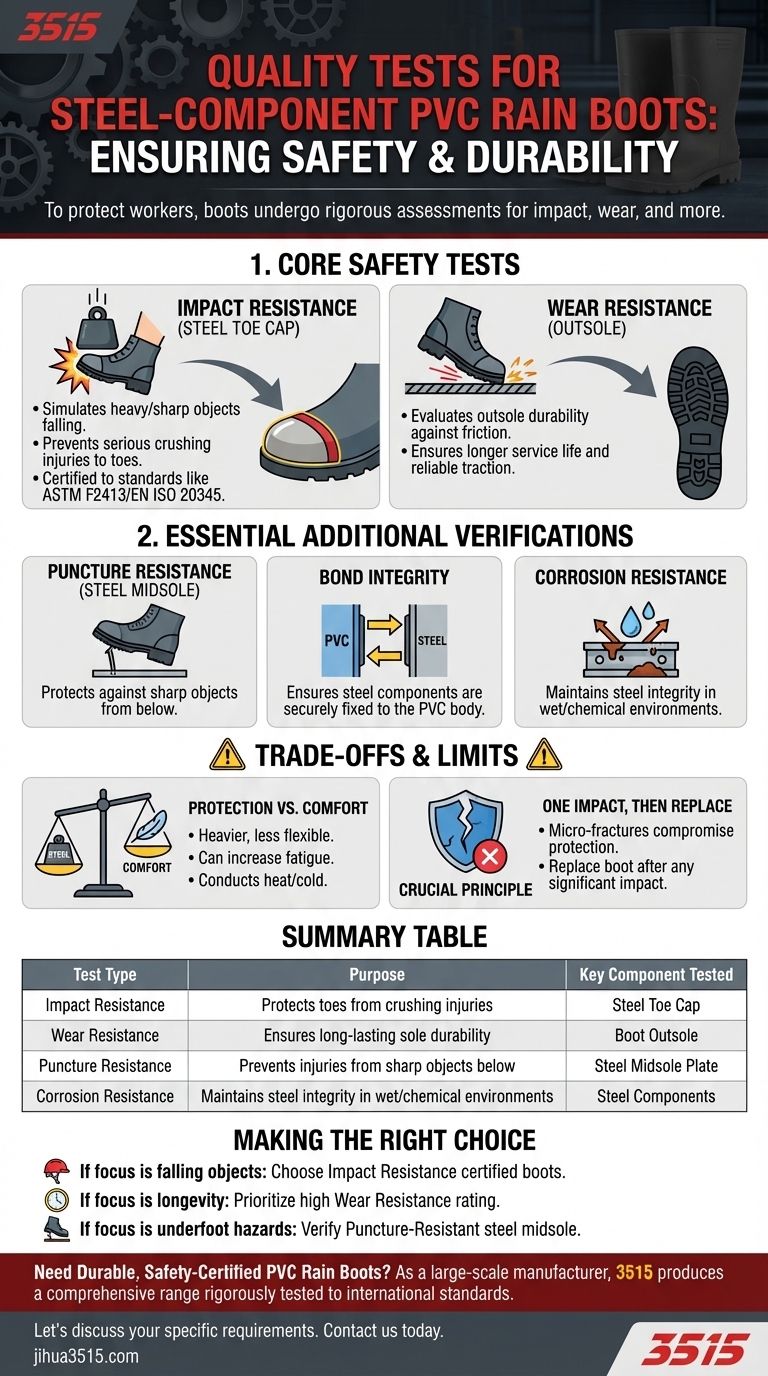

To ensure safety and durability, PVC rain boots equipped with steel components undergo two primary quality tests: impact resistance and wear resistance. These assessments are designed to verify the boot's ability to protect the wearer from crushing injuries caused by falling objects and to withstand the general rigors of a demanding work environment.

The quality testing of steel-component safety boots is not merely about product longevity; it is a critical process for verifying their core function—protecting the user from specific, identifiable workplace hazards.

Deconstructing the Core Safety Tests

The tests performed on these specialized boots directly correlate to the function of the steel components they contain. The steel toe cap is tested for impact, while the sole's material is tested for its overall hardiness.

The Critical Role of Impact Resistance

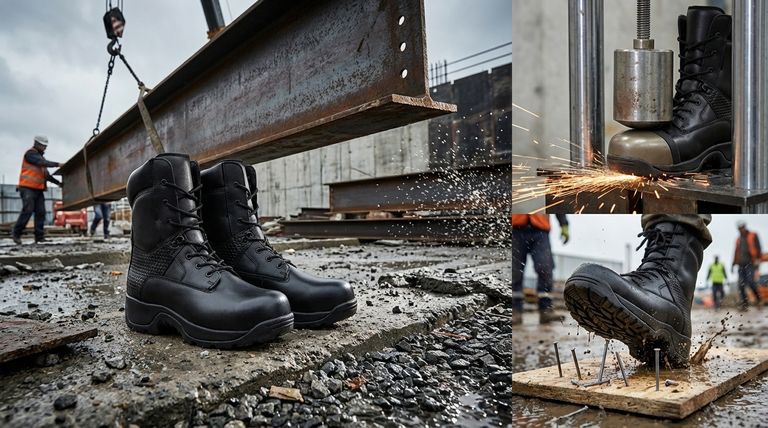

This test is the single most important assessment for a boot with a steel toe cap. It simulates a heavy or sharp object falling directly onto the front of the boot.

The goal is to ensure the steel cap can withstand a specified level of force without deforming to the point where it would injure the wearer's toes. This is a direct measure of the boot's ability to prevent serious crushing injuries.

Gauging Longevity with Wear Resistance

Wear resistance, often called abrasion resistance, evaluates the durability of the boot's outsole. The test measures how well the sole material holds up against friction and abrasive surfaces.

A high score in this test indicates that the boot will have a longer service life, maintain its tread, and provide reliable traction over time, even in rough conditions.

Beyond the Basics: Other Essential Verifications

While impact and wear resistance are fundamental, a comprehensive quality assessment for high-grade safety footwear often includes evaluating the other protective functions of the steel components.

Puncture Resistance for Underfoot Protection

If the "steel sole" refers to a steel midsole plate, its primary function is to protect the foot from sharp objects from below.

A puncture resistance test is performed by attempting to drive a sharp, nail-like object through the sole. This ensures the boot can prevent injuries from stepping on nails, screws, or other hazardous debris on a worksite.

The Integrity of the Bond

The connection between the PVC body of the boot and the embedded steel components is also critical. Tests may be conducted to ensure the steel toe cap cannot be dislodged or pushed out of place. A secure bond is essential for the safety features to function correctly during an incident.

Corrosion Resistance

The steel components themselves must be resistant to rust and corrosion. Exposure to water, mud, and chemicals can degrade unprotected steel over time, compromising its structural integrity and protective capabilities. Quality tests verify that the steel is properly treated or coated to resist environmental factors.

Understanding the Trade-offs

While providing superior protection, the inclusion of steel components introduces specific trade-offs that are important to acknowledge.

Protection vs. Comfort

Steel is significantly heavier and less flexible than PVC or composite safety materials. This adds weight to the boot, which can increase fatigue over a long workday. Steel components can also conduct heat and cold more readily than other materials.

The Limits of "Resistance"

It is crucial to understand that "impact-resistant" does not mean indestructible. These boots are tested and certified to a specific standard (e.g., ASTM F2413 in the US or EN ISO 20345 in Europe), which quantifies the exact level of impact energy they can withstand. Choosing a boot certified for the risks of your specific environment is paramount.

One Impact, Then Replacement

A key safety principle is that after a boot has sustained a significant impact, it should be replaced. The steel toe may have sustained micro-fractures that are not visible but have compromised its ability to protect against a future impact.

Making the Right Choice for Your Goal

To select the appropriate footwear, you must match the boot's tested capabilities to the known hazards of your environment.

- If your primary focus is protection from falling objects: Confirm the boots are certified for impact resistance to a standard that meets or exceeds the risks of your workplace.

- If your primary focus is longevity in abrasive conditions: Prioritize boots with a high rating for wear or abrasion resistance to ensure a longer service life and better value.

- If your primary focus is underfoot hazards: You must verify the boot contains a puncture-resistant steel midsole that has been tested to the relevant safety standard.

By understanding what these core quality tests truly measure, you can confidently select footwear that provides the specific protection and durability you require.

Summary Table:

| Test Type | Purpose | Key Component Tested |

|---|---|---|

| Impact Resistance | Protects toes from crushing injuries | Steel Toe Cap |

| Wear Resistance | Ensures long-lasting sole durability | Boot Outsole |

| Puncture Resistance | Prevents injuries from sharp objects below | Steel Midsole Plate |

| Corrosion Resistance | Maintains steel integrity in wet/chemical environments | Steel Components |

Need Durable, Safety-Certified PVC Rain Boots with Steel Components?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and rain boots, rigorously tested to meet international standards like ASTM F2413 and EN ISO 20345.

We ensure every pair delivers the critical protection and longevity your customers demand. Let's discuss your specific requirements and how we can support your business with reliable, high-quality footwear.

Contact us today for a consultation

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How can wellies be styled for different occasions? Master Rainy Day & Festival Fashion

- What is the significance of understanding the materials used in wellington boots? Choose the Right Boot for Your Needs

- What material are PVC boots made from? A Guide to Their Pros, Cons & Best Uses

- What are the benefits and drawbacks of neoprene-lined wellington boots? A Guide to Cold-Weather Footwear

- What is the quality and durability of the rubber boots? Engineered for Long-Lasting Performance

- What changes occurred in Wellington boots post-World War II? A Shift from Military Gear to Industrial Staple

- What are the long-term benefits of providing rubber boots to employees? Boost Morale & Efficiency

- What temporary solutions were mentioned for using less supportive footwear like wellies? Protect Your Feet Now