In today's global footwear market, the Goodyear welt construction method is exceptionally rare. It is used in approximately one percent of all shoes produced, making it a hallmark of high-quality, traditional shoemaking rather than a mainstream manufacturing technique.

The scarcity of Goodyear welted shoes is not a sign of obsolescence, but a reflection of their purpose. This method prioritizes long-term durability, repairability, and personalized comfort over the speed and low cost of mass-market production.

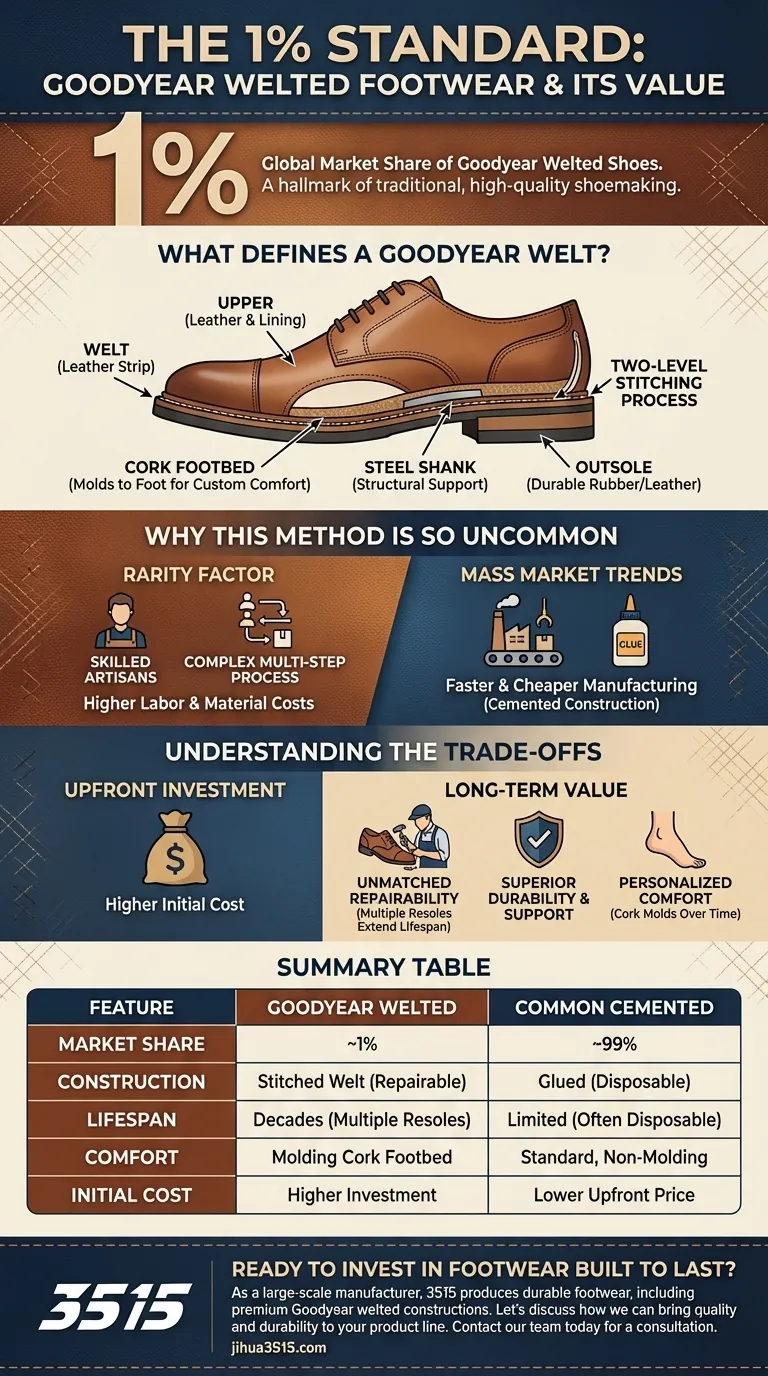

What Defines a Goodyear Welt?

A Goodyear welt is a specific, time-honored method of shoe construction. It fundamentally changes how the upper part of the shoe is attached to the sole, creating a uniquely robust and serviceable product.

The Key Components

The process involves a strip of leather—the welt—that runs along the perimeter of the shoe. This welt acts as a crucial intermediary, connecting the shoe's upper to its outsole.

A Two-Level Stitching Process

First, the upper leather and lining are stitched to the welt. Then, in a separate stitch, the welt is attached to the outsole. This creates an incredibly strong and water-resistant bond.

The Comfort Layer

This construction method creates a cavity between the insole and the outsole. This space is filled with a layer of granulated cork, which gradually molds to the shape of your foot, creating a custom-like fit over time. A metal shank is also embedded to provide structural support.

Why This Method Is So Uncommon

The one percent figure highlights a significant shift in the footwear industry towards faster and cheaper manufacturing methods. The Goodyear welt is a deliberate departure from this trend.

Labor and Material Costs

Goodyear welting is a complex, multi-step process that requires skilled artisans and more materials. This stands in stark contrast to the simple adhesive-based "cemented" construction used in most modern sneakers and casual shoes.

The Break-In Period

The durable materials and sturdy construction mean these shoes often have an initial stiffness. They require a break-in period for the leather to soften and the cork footbed to conform to the wearer, an investment of time many consumers are not accustomed to.

A Distinctive Aesthetic

The construction results in a unique and elegant appearance, with the upper curving slightly inwards from the edge of the sole. While prized in classic dress shoes and boots, this profile is less common in the world of streamlined, lightweight footwear.

Understanding the Trade-offs

Choosing a Goodyear welted shoe involves a clear set of benefits and considerations. It is an investment, not an impulse purchase.

The Upfront Investment

The most significant barrier is the initial cost. These shoes are more expensive due to the skilled labor and higher-quality materials involved in their construction.

Unmatched Repairability

The primary advantage is longevity. Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and attach a new one multiple times. This dramatically extends the life of the shoe far beyond what is possible with cemented footwear.

Superior Durability and Support

The stitched construction, cork filling, and integrated shank create a very sturdy and supportive platform. These shoes are built to withstand years of hard wear while maintaining their shape and structure.

Making the Right Choice for Your Goal

Understanding this construction method allows you to select footwear that aligns with your specific needs and values.

- If your primary focus is long-term value and sustainability: A Goodyear welted shoe is the clear choice, as it is designed to be repaired and worn for decades, not discarded.

- If your primary focus is the lowest possible price for casual wear: A cemented shoe will meet your needs, but you must accept it will have a limited and finite lifespan.

- If your primary focus is personalized comfort for daily wear: The investment in a Goodyear welted shoe pays off as the cork footbed molds to your foot, providing a level of custom support that mass-produced shoes cannot match.

Ultimately, choosing a Goodyear welted shoe is a decision to invest in craftsmanship, durability, and a more sustainable approach to your wardrobe.

Summary Table:

| Feature | Goodyear Welted Shoes | Common Cemented Shoes |

|---|---|---|

| Market Share | ~1% | ~99% |

| Construction | Stitched welt for repairability | Glued for low-cost production |

| Lifespan | Decades, with multiple resoles | Limited, often disposable |

| Comfort | Cork footbed molds to your foot | Standardized, non-molding fit |

| Initial Cost | Higher investment | Lower upfront price |

Ready to invest in footwear built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including premium Goodyear welted constructions that offer your customers unmatched longevity and value.

Let's discuss how we can bring quality and durability to your product line. Contact our team today for a consultation.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team