To accelerate the break-in process for new riding boots, the most effective approach is to combine consistent, low-impact wear with targeted methods that soften and stretch the leather. This involves wearing them around the house, applying leather conditioner to flex points like the ankle and heel, and carefully using moisture to help the leather mold to your specific anatomy.

The core principle is not to force the boot into submission, but to guide stiff leather to conform to your foot and leg. A successful break-in achieves a custom fit by encouraging the material to stretch and flex in key areas, preventing future discomfort and enhancing performance.

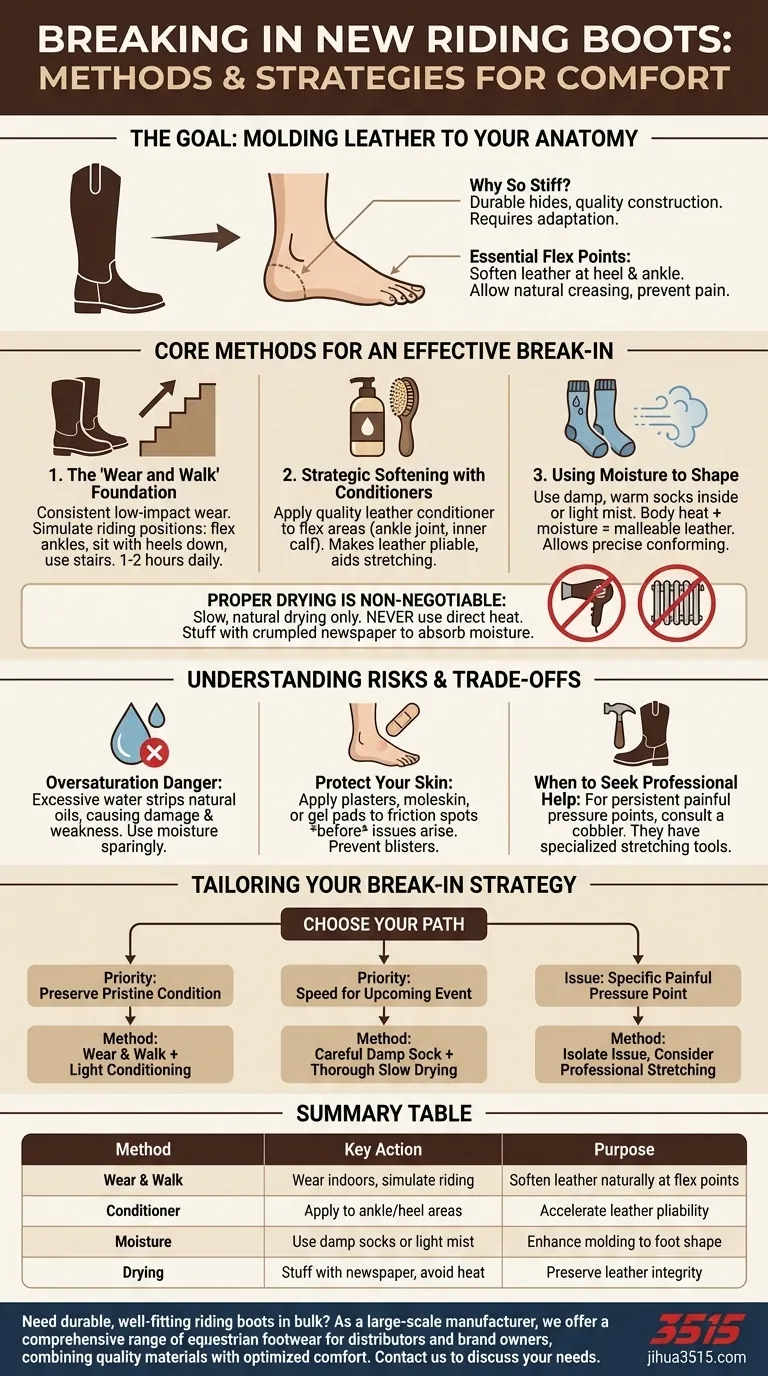

The Goal: Molding Leather to Your Anatomy

Why New Boots Feel So Stiff

New leather riding boots are constructed from durable, tanned hides designed for longevity and support. This initial rigidity, particularly around the ankle and heel, is a sign of quality but requires a dedicated period to adapt to your body's movement.

Creating Essential Flex Points

The break-in process is about creating flexibility where your body hinges. The primary goal is to soften the leather at the back of the heel and across the front of the ankle, allowing the boot to drop and crease naturally without causing pain or blisters.

Core Methods for an Effective Break-in

The 'Wear and Walk' Foundation

The simplest and safest method is consistent wear. Put on your boots with your typical riding socks and wear them around the house for an hour or two each day.

Actively simulate riding positions while wearing them. Sit down and press your heels down, flexing your ankles. Walk up and down stairs. This mimics the stresses of riding and encourages the boots to crease in the correct places.

Strategic Softening with Conditioners

Leather conditioner can significantly speed up the process by softening the material. Apply a small amount of a quality leather conditioner specifically to the areas that need to flex most—the ankle joint and the inner calf.

This targeted application makes the leather more pliable, allowing it to stretch and mold more easily during the 'wear and walk' phase.

Using Moisture to Shape the Leather

For a more aggressive approach, moisture can be used to help the leather stretch and form. The most common method is to wear a pair of damp, warm socks inside the boots until they dry.

Alternatively, you can lightly spray the inside of the boot with a fine mist of water before putting them on. The combination of moisture and your body heat makes the leather exceptionally malleable, allowing it to conform precisely to your foot and ankle.

Proper Drying is Non-Negotiable

If you use any water-based method, you must allow the boots to dry slowly and naturally. Never use direct heat like a hairdryer or radiator, as this will dry out the leather, making it brittle and prone to cracking.

To aid drying, stuff the boots with crumpled newspaper. The paper will absorb excess moisture from the inside. Replace the newspaper whenever it becomes damp.

Understanding the Risks and Trade-offs

The Danger of Oversaturation

While moisture is effective, overdoing it is the fastest way to damage your boots. Excessive water can strip the leather of its natural oils, leading to discoloration and permanent weakness in the material. Use the damp sock or light misting method sparingly.

Protecting Your Skin is Paramount

New boots are notorious for causing blisters, especially at the heel. Before you even start, apply plasters, moleskin, or gel pads to any known friction spots on your feet. Preventing a blister is far easier than trying to ride with one.

When to Seek Professional Help

If a specific spot on the boot creates a painful pressure point that doesn't resolve with these methods, do not force it. A professional cobbler has specialized tools that can stretch a precise area of the boot without damaging the surrounding structure.

Tailoring Your Break-in Strategy

The right approach depends on your timeline and the boot itself. Use these guidelines to choose the best path.

- If your primary focus is preserving the boot's pristine condition: Stick to the 'wear and walk' method combined with light, targeted conditioning on the ankle.

- If your primary focus is speed for an upcoming event: Carefully employ the damp sock method for short durations, ensuring you allow for thorough, slow drying afterward.

- If you experience a specific, painful pressure point: Isolate the issue and consider professional stretching by a cobbler to avoid damaging the boot or your foot.

A well-executed break-in period is the foundation for years of comfort and peak performance in the saddle.

Summary Table:

| Method | Key Action | Purpose |

|---|---|---|

| Wear & Walk | Wear boots indoors, simulate riding | Soften leather naturally at flex points |

| Conditioner | Apply to ankle/heel areas | Accelerate leather pliability |

| Moisture | Use damp socks or light mist | Enhance molding to foot shape |

| Drying | Stuff with newspaper, avoid heat | Preserve leather integrity |

Need durable, well-fitting riding boots in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian footwear for distributors, brand owners, and bulk clients. Our expertise ensures boots that combine quality materials with designs optimized for comfort and performance. Contact us today to discuss your specific needs and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why is rubber commonly used for non-slip soles? The Science of Superior Grip

- What should be avoided when storing boots with outsoles? Protect Your Investment from Dry Rot & Decay

- What types of rubber are typically employed in non-slip footwear soles? Your Guide to Maximum Grip and Safety

- What material should the sole of a non-slip shoe be made of? The Key to Maximum Traction

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability