At its core, rubber is the default material for non-slip soles because of two fundamental properties: a naturally high coefficient of friction and exceptional pliability. This combination allows it to generate powerful grip by conforming to microscopic surface irregularities, creating maximum contact area, a quality it maintains even when surfaces are wet or oily.

The true reason for rubber's dominance isn't just one feature, but its unique synthesis of molecular grip, flexibility, and durability. This trifecta delivers reliable slip resistance across a wider range of real-world conditions than most alternative materials.

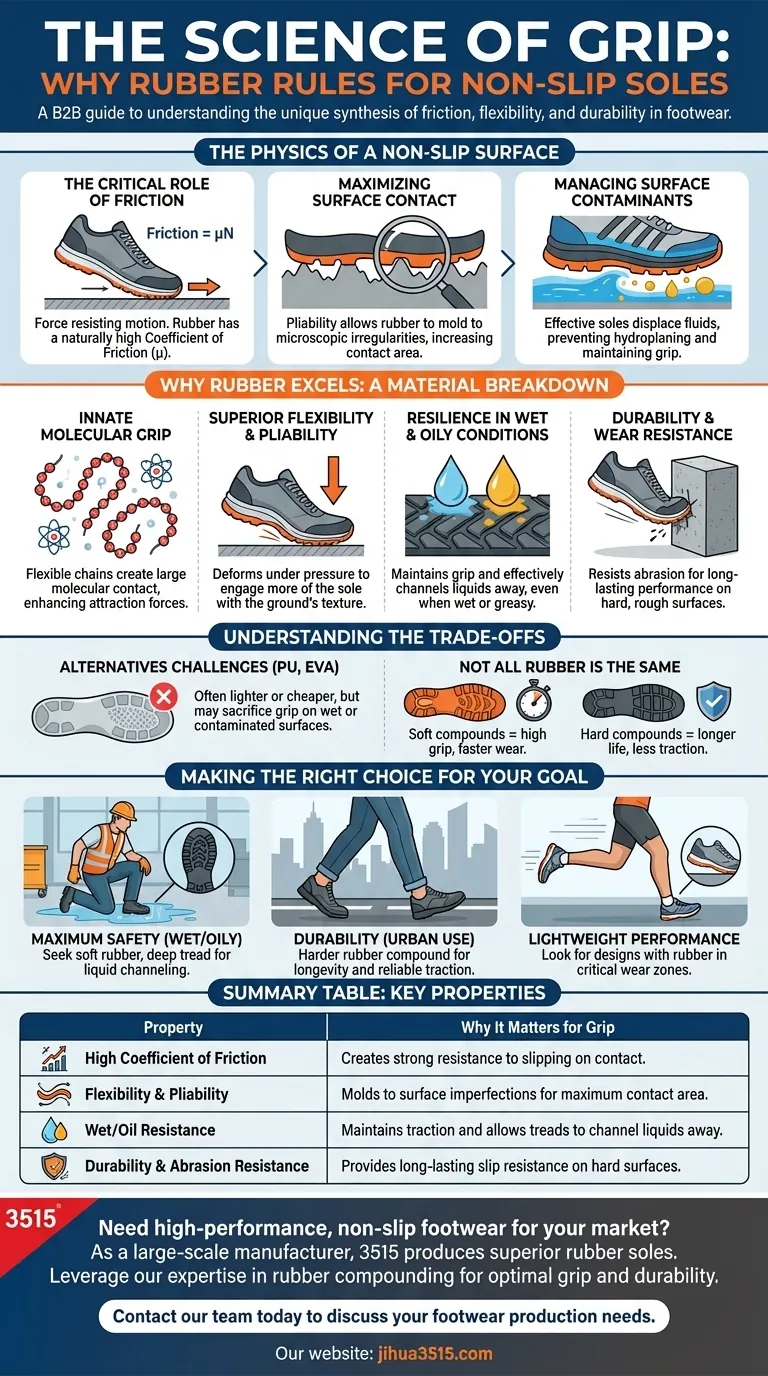

The Physics of a Non-Slip Surface

To understand why rubber is so effective, we first need to understand what "grip" actually is. It's a result of a few key physical principles working in concert.

The Critical Role of Friction

Friction is the force resisting motion between two surfaces in contact. A material's effectiveness at this is measured by its coefficient of friction.

Rubber naturally possesses a very high coefficient of friction. This means it requires more force to slide across a surface compared to materials like hard plastic or leather.

Maximizing Surface Contact

No surface is perfectly smooth. At a microscopic level, floors and pavements are covered in tiny peaks and valleys.

A material's ability to conform to these irregularities drastically increases the total surface area in contact, which in turn maximizes frictional force. Rubber's inherent pliability allows it to mold into these imperfections, creating a stronger hold.

Managing Surface Contaminants

The introduction of liquids like water or oil creates a thin film that separates the sole from the ground, causing a dramatic loss of friction—a phenomenon known as hydroplaning.

An effective non-slip sole must not only grip but also have a way to displace these fluids. This is achieved through both the material's properties and the physical design of its tread patterns, which act as channels to move liquid away from the point of contact.

Why Rubber Excels: A Material Breakdown

Rubber's chemical and physical structure makes it uniquely suited to address all three principles of grip.

Innate Molecular Grip

Unlike rigid materials, rubber's long, flexible polymer chains create a large contact area at a molecular level, enhancing the forces of attraction between the sole and the ground. This contributes directly to its high coefficient of friction.

Superior Flexibility and Pliability

As mentioned, rubber’s flexibility is key. It deforms under pressure to grip the texture of the ground, ensuring that as much of the sole as possible is engaged in creating friction.

Resilience in Wet and Oily Conditions

Rubber maintains a significant amount of its frictional properties even when wet. It resists being "lifted" by a film of water, allowing the tread to do its job of channeling the liquid away effectively. High-grade rubber compounds are also specifically formulated to grip greasy surfaces.

Durability and Wear Resistance

For a sole to be practical, its grip cannot come at the expense of longevity. Rubber is exceptionally durable and resistant to abrasion, making it ideal for repeated contact with hard, rough surfaces like concrete and asphalt.

Understanding the Trade-offs

While rubber is an excellent all-around choice, it's important to recognize that not all non-slip soles are created equal, and alternatives exist for specific reasons.

The Challenge of Alternatives

Materials like Polyurethane (PU) and EVA (ethylene vinyl acetate) are often used in footwear. They can offer benefits like being lighter or cheaper to produce.

However, these materials often represent a trade-off. They may not provide the same level of grip as high-quality rubber, especially on wet or contaminated surfaces.

Not All Rubber is the Same

The term "rubber" covers a wide range of natural and synthetic formulations. A soft rubber compound might offer phenomenal grip but wear out quickly. A harder compound will last longer but may sacrifice some traction.

The final performance of a sole depends heavily on the specific compound chosen by the manufacturer, which is tailored to the shoe's intended purpose.

Making the Right Choice for Your Goal

When selecting footwear, consider the primary environment it will be used in.

- If your primary focus is maximum safety in wet or oily environments: Seek out soles made of a soft rubber compound with deep, aggressive tread patterns designed to channel liquid.

- If your primary focus is durability for everyday urban use: A harder, wear-resistant rubber sole offers a great balance of longevity and reliable traction on concrete and asphalt.

- If your primary focus is lightweight athletic performance: You may encounter soles using EVA or other synthetic blends, but look for designs that strategically place high-traction rubber in critical wear zones like the heel and forefoot.

Ultimately, understanding these material properties allows you to look beyond marketing and choose footwear based on the science of grip.

Summary Table:

| Property | Why It Matters for Grip |

|---|---|

| High Coefficient of Friction | Creates strong resistance to slipping on contact. |

| Flexibility & Pliability | Molds to surface imperfections for maximum contact area. |

| Wet/Oil Resistance | Maintains traction and allows treads to channel liquids away. |

| Durability & Abrasion Resistance | Provides long-lasting slip resistance on hard surfaces. |

Need high-performance, non-slip footwear for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety, work, and outdoor footwear with superior rubber soles for distributors, brand owners, and bulk clients. Our expertise in rubber compounding ensures optimal grip and durability for any environment.

Contact our team today to discuss your footwear production needs and leverage our full-scale manufacturing capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health