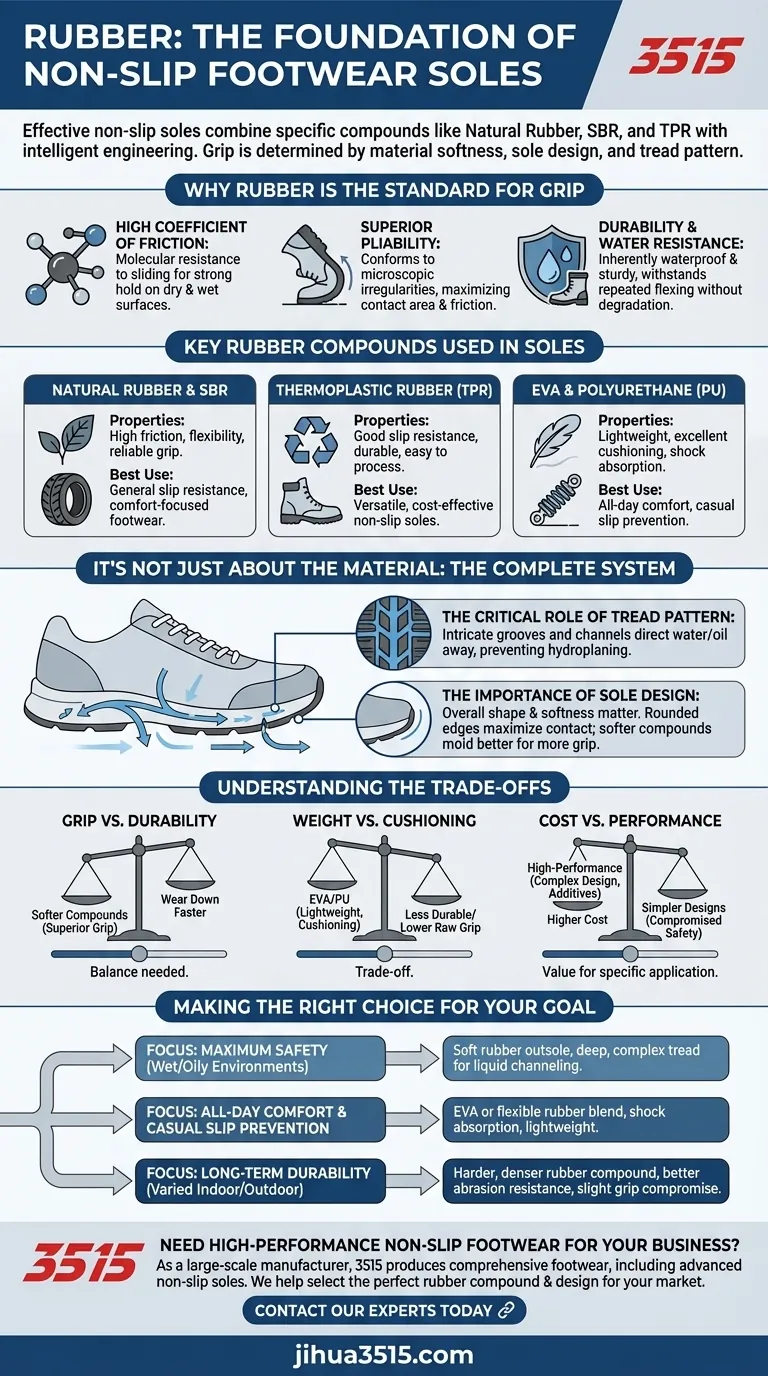

To create effective non-slip footwear, manufacturers primarily use specific compounds like Natural Rubber, Styrene-Butadiene Rubber (SBR), and Thermoplastic Rubber (TPR). These materials are chosen for their inherently high friction, flexibility, and ability to maintain grip even on wet or contaminated surfaces.

The specific type of rubber used is only one part of the equation. A shoe's true slip resistance is determined by a combination of the rubber compound's softness, the sole's overall design, and a tread pattern engineered to channel away liquids.

Why Rubber is the Standard for Grip

Rubber's dominance in non-slip soles isn't accidental. It stems from a unique combination of physical properties that make it ideal for generating traction underfoot.

High Coefficient of Friction

At a molecular level, rubber has a naturally high resistance to sliding. This inherent "grippiness" is the foundation of its performance, providing a strong hold on both dry and wet surfaces.

Superior Pliability

Rubber is flexible and soft. This allows it to conform to microscopic irregularities on a walking surface, maximizing the contact area and creating more points of friction.

Durability and Water Resistance

Unlike materials such as leather, rubber is inherently waterproof and sturdy. It can be molded into complex designs and withstand repeated flexing without significant degradation, protecting both the wearer and the shoe itself.

Key Rubber Compounds Used in Soles

While "rubber" is often used as a blanket term, different compounds offer distinct advantages in flexibility, durability, and weight.

Natural Rubber and SBR

Natural rubber and its synthetic counterpart, Styrene-Butadiene Rubber (SBR), are classic choices known for excellent frictional properties and flexibility. They provide reliable traction and a comfortable walking experience.

Thermoplastic Rubber (TPR)

TPR is a synthetic material that blends the properties of rubber with the easy processing of plastic. It offers good slip resistance and durability, making it a common choice for a wide range of footwear.

EVA and Polyurethane (PU)

Ethylene-vinyl acetate (EVA) is a foam-like rubber material that is extremely lightweight and provides excellent shock absorption. Polyurethane (PU) is also known for being lightweight and durable. Both are often used in soles where comfort and reduced weight are as important as grip.

It's Not Just About the Material

Believing any rubber-soled shoe is non-slip is a common and dangerous misconception. The material is the starting point, but the engineering of the sole is what delivers genuine safety.

The Critical Role of Tread Pattern

The single most important factor after the material itself is the tread pattern. Effective non-slip soles have intricate grooves and channels designed to direct water, oil, and other contaminants away from the point of contact. This prevents a layer of liquid from forming between the shoe and the floor, a phenomenon known as hydroplaning.

The Importance of Sole Design

The overall shape and softness of the outsole matter. A good non-slip sole is often slightly rounded on the edges to maximize contact during a misstep. A softer compound provides more grip because it can better mold to the surface, though this often comes at the expense of longevity.

Understanding the Trade-offs

Choosing the right material for a non-slip sole involves balancing competing priorities. There is no single "best" material, only the best material for a specific application.

Grip vs. Durability

This is the primary trade-off. Softer rubber compounds provide superior grip because they have more "give" and can create more surface contact. However, this same softness means they wear down much faster, especially on abrasive surfaces like concrete or asphalt.

Weight vs. Cushioning

Materials like EVA offer fantastic cushioning and are incredibly lightweight, reducing foot fatigue. The trade-off is that they may not be as durable or provide the same level of raw grip on oily surfaces as denser, heavier rubber compounds.

Cost vs. Performance

High-performance rubber compounds with specialized additives and complex, molded tread patterns are more expensive to produce. Cheaper soles may use less effective materials or simpler designs, resulting in compromised safety.

Making the Right Choice for Your Goal

When evaluating non-slip footwear, consider the environment where you will use it most.

- If your primary focus is maximum safety in hazardous (wet or oily) environments: Look for shoes with soft rubber outsoles and a deep, complex tread pattern specifically designed to channel liquids.

- If your primary focus is all-day comfort and casual slip prevention: A sole made of EVA or a flexible rubber blend offers an excellent balance of shock absorption, lightweight feel, and reliable traction for general use.

- If your primary focus is long-term durability for varied indoor/outdoor use: A harder, denser rubber compound will withstand abrasion better, even if it means a slight compromise on grip in the most extreme conditions.

Ultimately, effective slip resistance is a complete system where the right material is enhanced by an intelligent and purposeful design.

Summary Table:

| Material | Key Properties | Best Use Case |

|---|---|---|

| Natural Rubber / SBR | High friction, flexibility, reliable grip | General slip resistance, comfort-focused footwear |

| Thermoplastic Rubber (TPR) | Good slip resistance, durable, easy to process | Versatile, cost-effective non-slip soles |

| EVA / Polyurethane (PU) | Lightweight, excellent cushioning, shock absorption | All-day comfort, casual slip prevention |

Need high-performance non-slip footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those with advanced non-slip soles engineered for maximum safety and durability. We can help you select the perfect rubber compound and sole design for your specific application and target market.

Contact our experts today to discuss your custom footwear needs and request a quote.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

People Also Ask

- What are non-slip shoes? Essential Safety Footwear for High-Risk Workplaces

- Are slip-resistant shoes useful outside of hazardous work environments? Boost Your Everyday Safety

- What features make safety clogs suitable for hygienic environments? Slip-Resistant, Easy-to-Clean Design

- How do slip resistant shoes contribute to day-to-day comfort and long-term foot health? Beyond Safety, a Foundation for Well-being

- What are oil-resistant shoes and boots designed for? Protect Your Footwear from Oil Damage

- What are the components of an ideal non-slip work shoe? Engineered for Ultimate Safety & Comfort

- How are slip-resistant shoes certified for safety? Ensure Workplace Safety with Certified Footwear

- What advantages does ergonomic footwear provide? Maximize Protection and Comfort for High-Standing Occupations