This boot is engineered for heavy-duty work environments, specifically where chemical exposure is a primary concern. It is most suitable for professionals in the oil and gas industry and certain manufacturing settings that handle corrosive or hazardous substances.

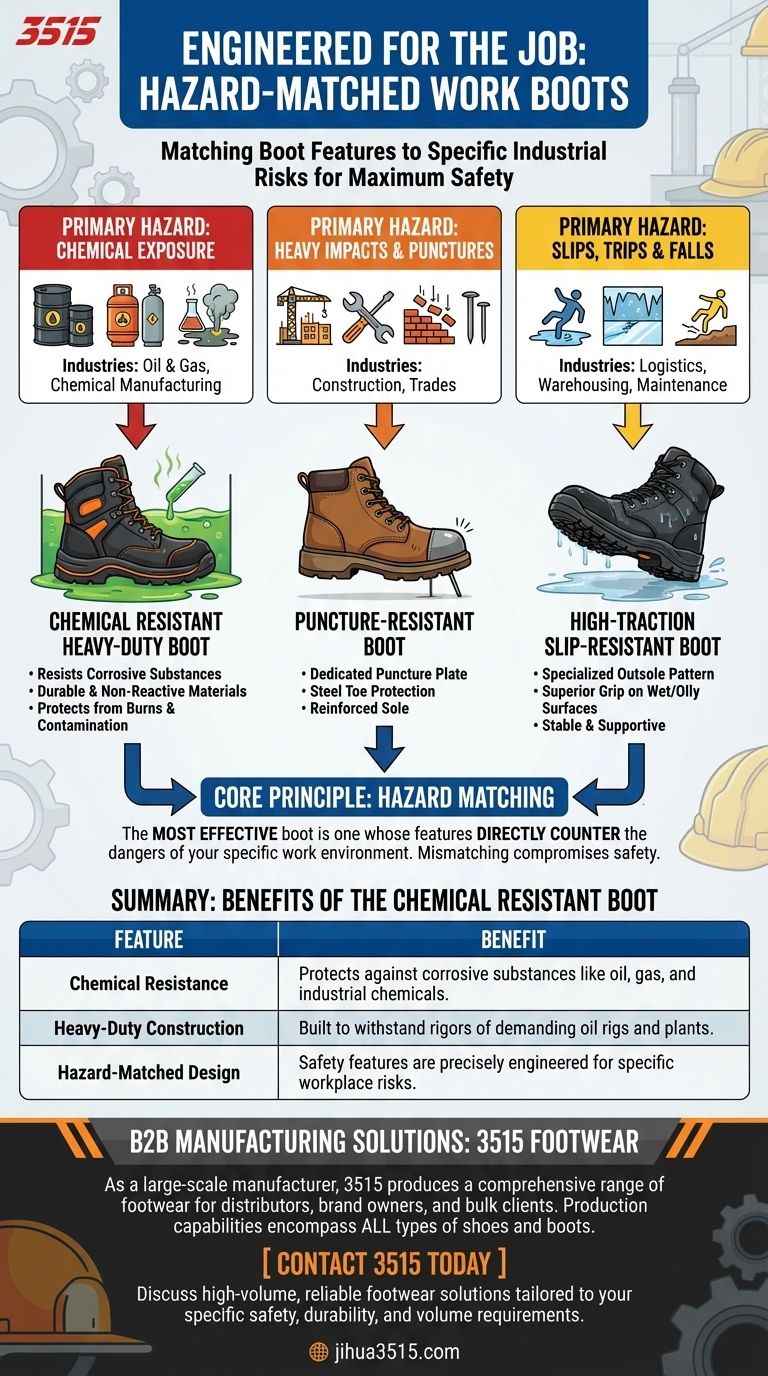

Choosing the right work boot is not about finding the "best" boot, but about precisely matching the boot's protective features to the specific hazards you face on the job every day.

Why Industry-Specific Design is Critical

Selecting a work boot is a critical safety decision. The design of a boot is a direct response to a set of known risks, and understanding this connection is the key to ensuring your protection and comfort.

The Core Principle: Hazard Matching

No single boot is perfect for every job. The most effective work boot is one whose features directly counter the dangers of your specific work environment.

This means evaluating your daily tasks and identifying the primary risks, whether they are chemical spills, falling objects, slippery surfaces, or electrical currents.

Engineered for Chemical Resistance

The standout feature of this boot is its ability to withstand exposure to chemicals. This is a non-negotiable requirement in industries like oil and gas.

Materials are chosen for their durability and non-reactivity, ensuring the boot's integrity doesn't degrade when exposed to corrosive materials, protecting your feet from burns and contamination.

Built for Heavy-Duty Demands

Beyond chemical resistance, this boot is designed for the rigors of heavy-duty work. This implies a robust construction that can handle long hours on hard surfaces and protect against impacts.

This level of durability is essential in both manufacturing plants and on oil rigs, where equipment is heavy and the environment is unforgiving.

Common Pitfalls to Avoid

Even a high-quality, specialized boot can be the wrong choice if it doesn't align with your full scope of work or personal needs. Overlooking key details can compromise both safety and productivity.

Mismatching the Primary Hazard

A common mistake is choosing a boot for a secondary risk. For example, while this boot is durable, its primary strength is chemical resistance.

If your main hazard is the risk of nail punctures on a construction site, a boot with a dedicated puncture-resistant plate would be a more appropriate choice, even if chemicals are a minor concern.

Neglecting Comfort and Support

Safety features are paramount, but a boot that causes discomfort or fatigue is a liability. Long shifts can lead to pain and distraction, which increases the risk of accidents.

Always ensure that any boot you choose provides adequate arch support and cushioning for the duration of your workday. The safest boot is one you can wear comfortably and confidently.

Making the Right Choice for Your Goal

Use your primary daily hazard as the deciding factor to ensure you get the protection you truly need.

- If your primary focus is working around oil, gas, or industrial chemicals: This boot is specifically engineered for the hazards you face daily.

- If your primary focus is construction or trades with puncture risks: Prioritize a boot with a confirmed puncture-resistant sole, as that is your most immediate danger.

- If your primary focus is working on slippery or uneven surfaces: Look for a boot with a high-traction, slip-resistant outsole designed for your specific floor type.

Ultimately, the right boot empowers you to perform your job safely and effectively.

Summary Table:

| Feature | Benefit |

|---|---|

| Chemical Resistance | Protects against corrosive substances like oil, gas, and industrial chemicals. |

| Heavy-Duty Construction | Built to withstand the rigors of demanding environments like oil rigs and plants. |

| Hazard-Matched Design | Safety features are precisely engineered for specific workplace risks. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots.

Need reliable, high-volume footwear solutions for your workforce? Contact 3515 today to discuss how our manufacturing expertise can meet your specific requirements for safety, durability, and volume.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the cons of Stitch-down Construction? A Guide to Its Key Trade-offs

- Why is size important when selecting PVC work boots? Ensure All-Day Comfort & Job Site Safety

- What are the important characteristics for work boot soles? Match the Sole to Your Job for Safety & Comfort

- How does the boot's waterproofing system work? A Guide to Staying Dry

- What are the key features of logger boots? A Guide to Unmatched Stability & Safety

- What are the common foot issues workers face due to uncomfortable work boots? Prevent Pain & Deformities

- What type of insulation is best for colder temperatures with medium activity? Choose 600g for the Perfect Balance

- How can work boots be made suitable for winter? Master the 3-Pillar System for Warmth & Safety