At their core, Western boots are built from leather. This has been the traditional material for centuries, prized for its durability, comfort, and ability to be shaped. However, the modern Western boot often incorporates other specialized materials, such as rubber for outsoles and advanced synthetics for internal components, to enhance performance for specific uses like work or riding.

While the classic Western boot is defined by its leather construction, the true mark of quality lies in how specific materials are strategically chosen for each part of the boot to optimize durability, comfort, and function.

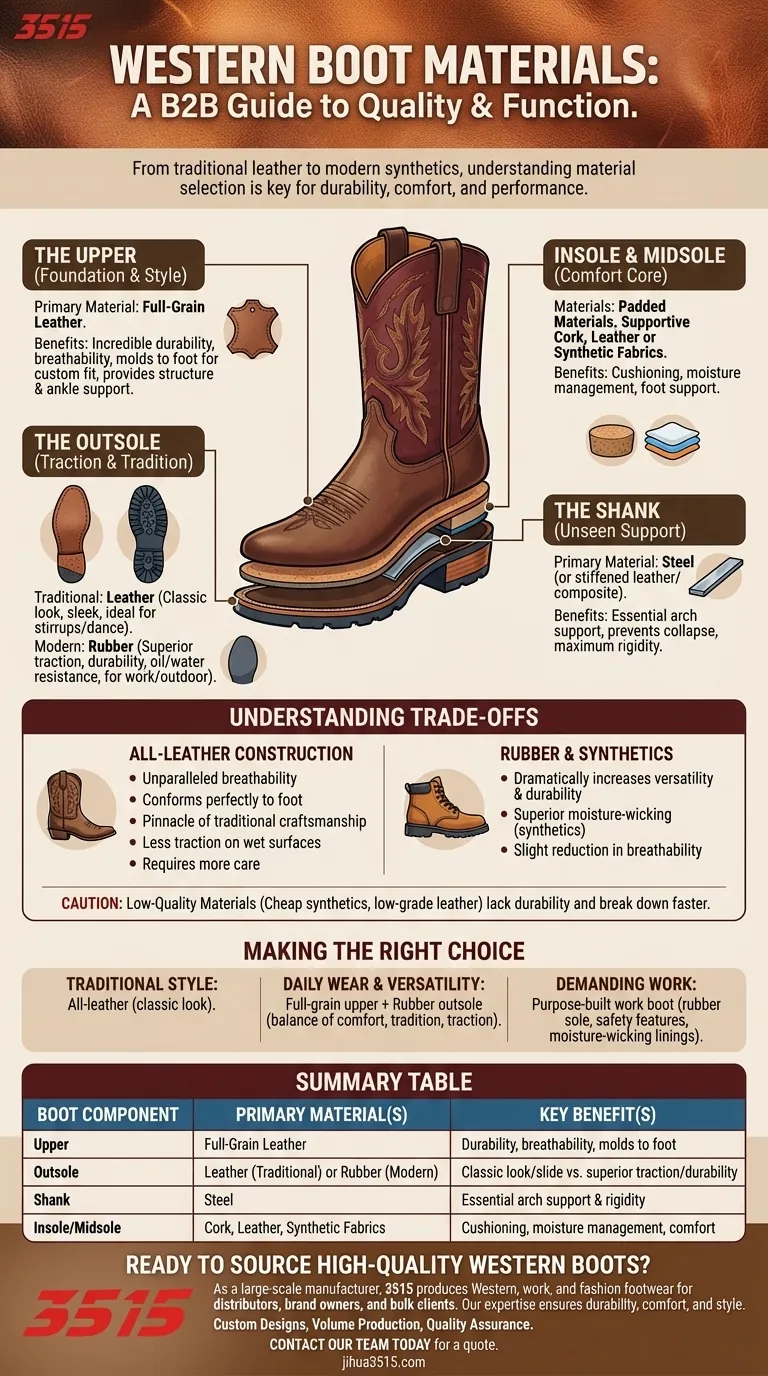

The Anatomy of a Western Boot: A Material Breakdown

A high-quality boot is more than just its outer shell. It's an engineered system where each material serves a distinct purpose. Understanding these components is key to appreciating the craftsmanship.

The Upper: The Foundation of Durability and Style

The upper is the main body of the boot that covers your foot and ankle. The undisputed champion material here is full-grain leather.

This type of leather is the highest quality available, known for its incredible durability, natural breathability, and ability to mold to the wearer's foot over time for a custom fit. It provides the essential structure and ankle support the boot is known for.

The Outsole: Where Tradition Meets Traction

The outsole is the part of the boot that makes direct contact with the ground. This is where you'll see the biggest variation based on the boot's intended use.

A traditional leather outsole is classic, sleek, and ideal for sliding in and out of a stirrup or gliding across a dance floor.

A modern rubber outsole is prized for its superior traction, durability, and resistance to oil or water. This is the standard choice for Western work boots or boots intended for heavy outdoor use.

The Insole and Midsole: The Core of Comfort

Hidden inside the boot, the insole and midsole provide cushioning, manage moisture, and support your foot.

These components are typically made from a combination of padded materials, supportive cork, and often lined with thin leather or moisture-wicking synthetic fabrics to keep the foot dry and comfortable.

The Shank: The Unseen Support System

The shank is a rigid strip placed between the insole and the outsole, running under the arch of your foot. This critical component prevents the boot from collapsing and provides essential arch support.

Shanks are almost always made from steel for maximum rigidity, though some boots may use stiffened leather or composite materials like fiberglass.

Understanding the Trade-offs

The choice between traditional and modern materials isn't about one being universally better; it's about matching the material to the mission.

The Case for All-Leather Construction

A boot made entirely of leather (upper, insole, and outsole) offers unparalleled breathability and the ability to conform perfectly to your foot. It represents the pinnacle of traditional craftsmanship.

However, a leather sole offers less traction on wet or slick surfaces and requires more diligent care and maintenance to protect it from the elements.

The Role of Rubber and Synthetics

Integrating rubber for the outsole dramatically increases a boot's versatility and durability for everyday wear, especially on pavement or in wet conditions.

Likewise, synthetic lining materials can offer superior moisture-wicking for active use. The trade-off is often a slight reduction in the boot's ability to "breathe" compared to an all-leather interior.

The Pitfall of Low-Quality Materials

Be cautious of boots with uppers made from cheap synthetic leathers or low-grade "genuine leather." These materials lack the durability, breathability, and comfort of full-grain leather and will break down much faster, failing to provide the long-term value expected from a quality Western boot.

Making the Right Choice for Your Needs

Your ideal boot depends entirely on your primary use case.

- If your primary focus is traditional style and formal wear: An all-leather boot with a leather outsole offers the most classic look and authentic feel.

- If your primary focus is daily wear and versatility: A full-grain leather upper with a durable rubber outsole provides the best balance of comfort, tradition, and all-weather traction.

- If your primary focus is demanding work or harsh conditions: A purpose-built work boot with a rubber sole, potential safety features like steel toes, and moisture-wicking synthetic linings is essential.

Understanding these materials empowers you to select a boot that is not just an accessory, but a reliable tool built for your purpose.

Summary Table:

| Boot Component | Primary Material(s) | Key Benefit(s) |

|---|---|---|

| Upper | Full-Grain Leather | Durability, breathability, molds to foot |

| Outsole | Leather (Traditional) or Rubber (Modern) | Classic look/slide vs. superior traction/durability |

| Shank | Steel | Essential arch support and rigidity |

| Insole/Midsole | Cork, Leather, Synthetic Fabrics | Cushioning, moisture management, comfort |

Ready to Source High-Quality Western Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of Western, work, and fashion footwear for distributors, brand owners, and bulk clients. Our expertise in material selection—from premium full-grain leathers to high-performance rubber compounds—ensures your boots are built for durability, comfort, and style.

Let's discuss your specific needs:

- Custom Designs: Tailor materials and construction to your target market.

- Volume Production: Reliable, large-scale manufacturing to meet your demand.

- Quality Assurance: Boots engineered to provide long-term value.

Contact our team today to get a quote and learn how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What should be done before wearing new work boots for the first time? A 3-Step Guide for Optimal Fit & Durability

- What are the initial steps to take care of new work boots? Ensure Long-Term Comfort and Durability

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health