In short, fire boots achieve their durability and safety through a strategic combination of specialized materials, primarily fire-resistant leather for the upper, vulcanized rubber for the sole, and composite materials like Kevlar for internal protection. Each material is chosen for its specific ability to resist the unique hazards of a fire scene, from extreme heat to physical impact.

The core principle behind fire boot construction is that no single material can provide complete protection. Instead, durability and safety are engineered by layering materials, each serving a distinct protective function—resisting heat, preventing punctures, and withstanding extreme wear.

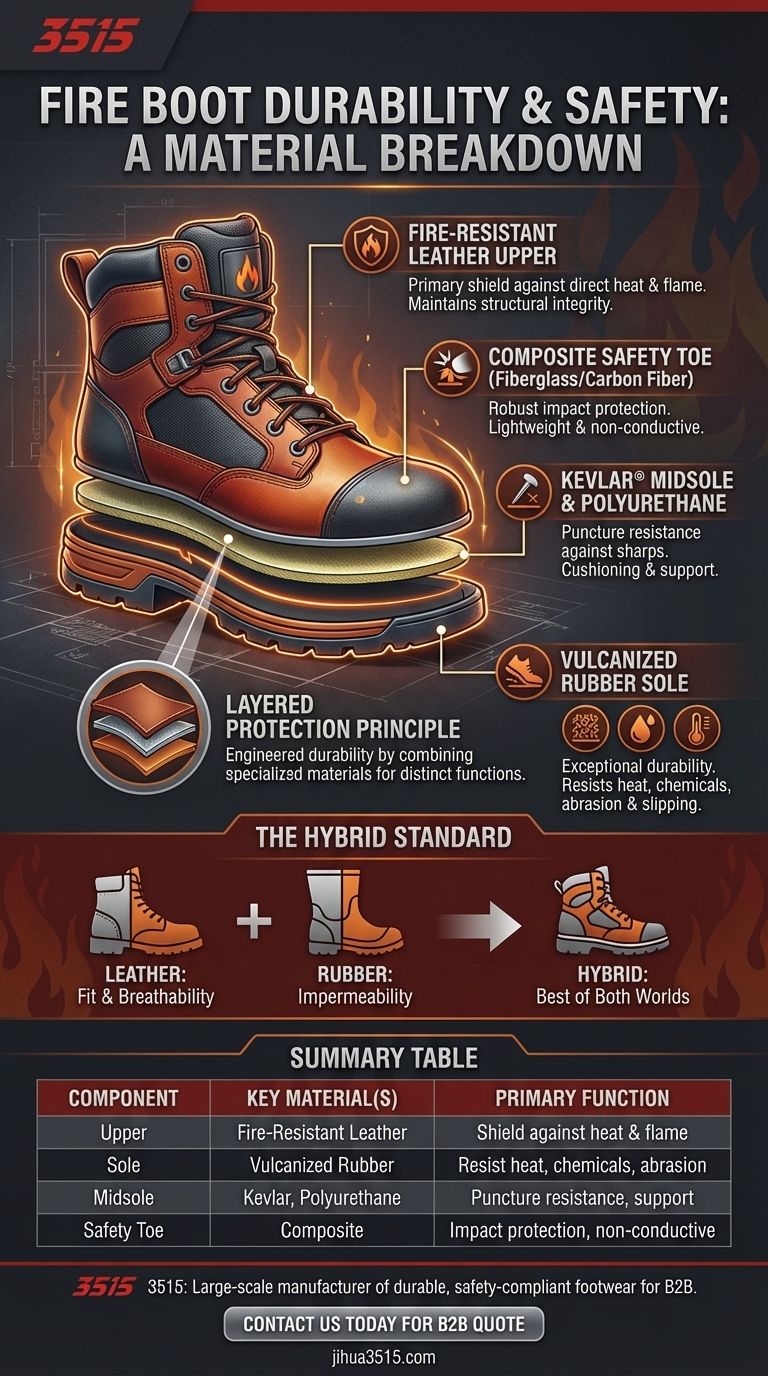

The Anatomy of a Fire Boot: A Material Breakdown

A fire boot is a system of components working together. Understanding the materials used in each part reveals why they are so effective at protecting the wearer in hazardous environments.

The Upper: The First Line of Defense

The upper portion of the boot is typically made from premium, fire-resistant leather. This is the boot's primary shield against direct heat and flame.

Unlike synthetics that can melt or soften at high temperatures, high-quality leather maintains its structural integrity. This ensures the boot continues to provide protection even when exposed to intense heat. The stitching that holds the leather together is also made from fire-resistant thread.

The Sole: The Foundation of Durability

The outsole is almost universally constructed from vulcanized rubber. This process strengthens the rubber, making it exceptionally durable and resistant to heat, chemicals, and abrasion.

Rubber provides superior wear and tear resistance compared to materials like PVC or neoprene, which are more suited for less demanding conditions. This ensures a stable, slip-resistant foundation on unpredictable surfaces.

The Midsole: Puncture Resistance and Support

Embedded between the insole and outsole is the midsole, which often contains a protective layer made of Kevlar. This composite material is lightweight yet incredibly strong, designed to prevent sharp objects like nails or glass from puncturing the sole.

For cushioning and support during long hours on your feet, materials like Polyurethane (PU) are also used, providing a stable yet flexible base.

The Safety Toe: Critical Impact Protection

To protect against falling or rolling objects, fire boots incorporate a safety toe cap. While steel is a traditional option, modern boots often use composite materials like fiberglass or carbon fiber.

These composites offer robust impact protection at a fraction of the weight of steel. Critically, they also do not conduct heat or cold, adding another layer of thermal protection for the wearer.

Understanding the Trade-offs

While modern fire boots integrate multiple materials, the primary choice between an all-leather or an all-rubber boot often comes down to the specific environment and hazards you face most frequently.

Leather's Advantage: Fit and Breathability

Leather boots offer a more structured, form-fitting feel that can provide better ankle support. They also offer a degree of natural breathability that is difficult to achieve with solid rubber construction.

Rubber's Advantage: Impermeability

Vulcanized rubber boots provide superior protection against water and chemicals. Their seamless construction creates an impermeable barrier, which is critical in situations involving hazardous liquids or deep water.

The Modern Hybrid Standard

Most top-tier structural firefighting boots today utilize a hybrid design. They feature a durable leather upper for heat resistance and support, combined with a robust rubber lower and sole for durability, water protection, and grip. This approach leverages the best properties of each material.

Making the Right Choice for Your Role

Selecting the right boot requires matching its material composition to the most probable hazards you will encounter.

- If your primary hazard is extreme ambient heat and flame contact: Prioritize a boot with a high-quality, thick, fire-resistant leather upper.

- If your role involves frequent water, chemical, or hazmat exposure: A vulcanized rubber boot offers the most reliable barrier against liquid penetration.

- If your chief concern is debris, impact, and puncture risks: Ensure the boot has a certified composite safety toe and a puncture-resistant Kevlar midsole plate.

Ultimately, understanding how these advanced materials work together empowers you to choose the equipment that will keep you safe and effective on the job.

Summary Table:

| Component | Key Material(s) | Primary Function |

|---|---|---|

| Upper | Fire-Resistant Leather | Shield against direct heat and flame |

| Sole | Vulcanized Rubber | Resist heat, chemicals, and abrasion |

| Midsole | Kevlar, Polyurethane | Puncture resistance and foot support |

| Safety Toe | Composite (Fiberglass, Carbon Fiber) | Impact protection, non-conductive |

Need high-performance fire boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, ensuring your team is equipped with the best protection against heat, punctures, and chemicals.

Contact us today to discuss your custom requirements and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why are safety boots designated as a core detection target in PPE monitoring? Enhance Industrial Safety Compliance

- What are the main similarities between PVC, neoprene, and rubber work boots? The Key Waterproof Trait Explained

- What is the traditional material used for cowboy boots? Discover the Durable Legacy of Cowhide

- Why are pull-on boots not suitable for wildland firefighting? The Critical Safety Flaw Explained

- How should full grain leather, suede, and nubuck boots be maintained? Protect Your Investment with Proper Care

- How are work boot insulation ratings measured? A Guide to Choosing the Right Warmth

- What are the characteristics of nylon work boots? Lightweight, Breathable & All-Day Comfort

- Where can heavy duty work boots be purchased? Find the Right Supplier for Your Needs