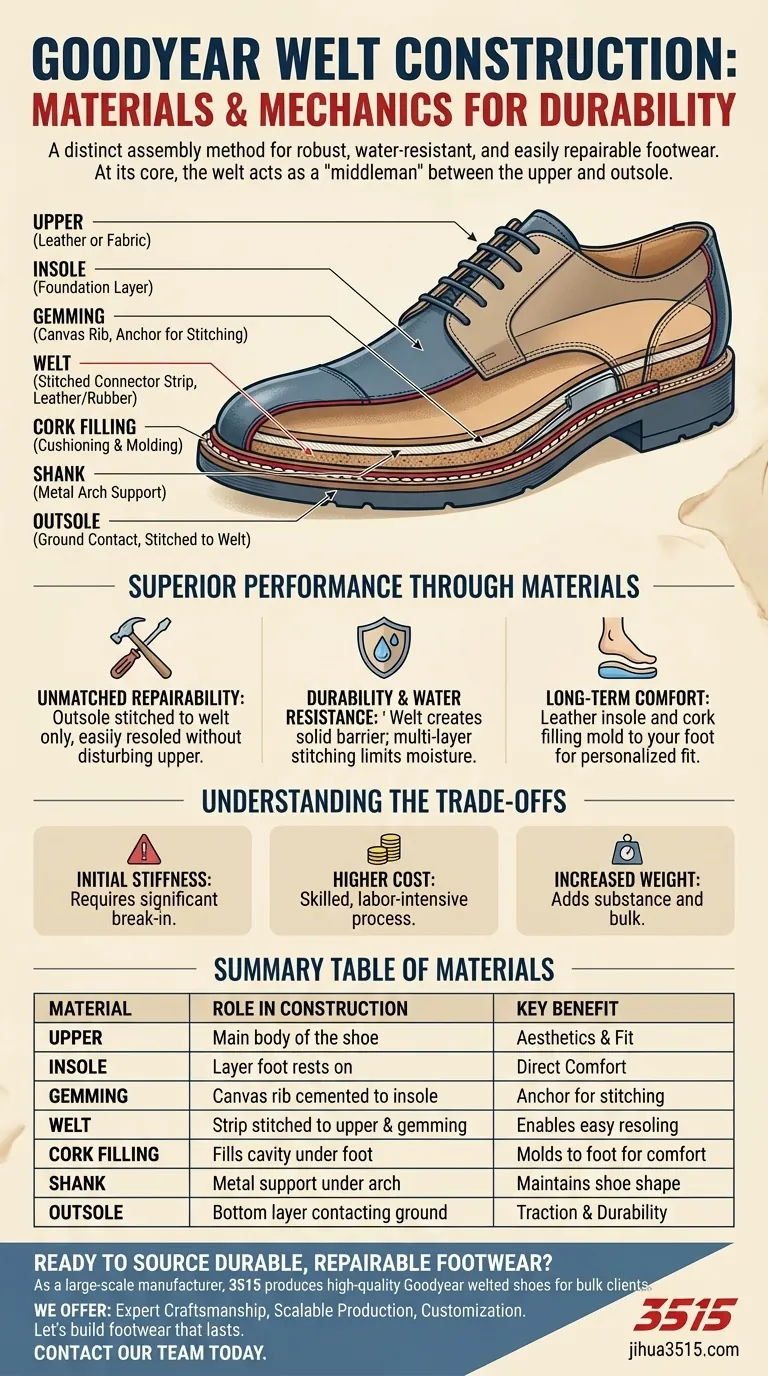

At its core, Goodyear welt construction uses a distinct set of materials to create a durable, water-resistant, and easily repairable shoe. The key components are the upper, the insole, a canvas rib known as gemming, a strip of leather or rubber called the welt, a cork filling, a supportive metal shank, and the outsole. These materials are layered and stitched together in a way that isolates the upper from the sole, which is the defining feature of this method.

The genius of the Goodyear welt lies in its materials and structure. By using a welt as a "middleman" between the upper and the outsole, and filling the resulting cavity with cork, the construction creates a shoe that is not only robust and weather-resistant but can be resoled repeatedly without compromising the integrity of the main shoe body.

The Anatomy of a Goodyear Welted Shoe

To understand why this construction is so highly regarded, you must first understand the specific role each material plays in the shoe's architecture.

The Upper and Insole: The Foundation

The process begins with the shoe's main body, the upper, which is the leather or fabric part that covers the foot. This is attached to the insole, the layer your foot rests on directly.

The Gemming: The Unsung Hero

A crucial and often unseen component is the gemming. This is a durable canvas rib that is cemented to the perimeter of the insole. It acts as the primary anchor point for the stitching that holds the entire shoe together.

The Welt: The Critical Connector

The welt is the material that gives the construction its name. It is a sturdy strip, typically made of leather, rubber, or plastic (PVC), that is stitched through the upper and into the canvas gemming. It forms a distinct outer rim around the base of the shoe.

The Cork Filling: For Comfort and Breathability

The space enclosed by the welt, between the insole and the outsole, creates a cavity. This cavity is filled with a layer of granulated cork. This natural material provides excellent cushioning, insulation, and breathability. Over time, it compresses and molds to the unique shape of your foot.

The Shank: The Structural Backbone

A small, rigid piece of metal called a shank is embedded within the cork layer. It sits under the arch of the foot, providing crucial support and ensuring the shoe maintains its shape over years of wear.

The Outsole: The Final Layer

Finally, the outsole—the part that contacts the ground—is attached. In a Goodyear welt, the outsole is stitched directly to the welt, not to the upper. This is the most important detail for repairability.

How These Materials Create Superior Performance

The specific combination and assembly of these materials deliver the three key benefits associated with Goodyear welted footwear.

Unmatched Repairability

Because the outsole is only stitched to the welt, a cobbler can easily cut those stitches, remove the old sole, and attach a new one. This process never disturbs the upper, allowing the shoe to be resoled multiple times.

Durability and Water Resistance

The welt creates a solid barrier around the edge of the shoe, and the multiple layers with their secure stitching make the construction exceptionally robust. This design significantly limits water from seeping into the shoe from below.

Long-Term Comfort

While often stiff at first, the shoe becomes uniquely comfortable over time. The leather insole and the cork filling gradually mold to the contours of your foot, creating a personalized fit that cannot be replicated by other methods.

Understanding the Trade-offs

This method is a benchmark for quality, but it's important to recognize the inherent trade-offs that come with its complex material structure.

Initial Stiffness

The multiple layers and robust materials mean Goodyear welted shoes require a significant break-in period. They will not feel flexible or perfectly comfortable straight out of the box.

Higher Cost

The quality of the materials and the skilled, labor-intensive process required to assemble them correctly result in a higher initial purchase price compared to simpler cemented or Blake-stitched shoes.

Increased Weight and Bulk

The addition of the welt, cork filling, and extra stitching adds weight and creates a more substantial silhouette. These are generally not sleek or lightweight shoes.

Making the Right Choice for Your Goal

Ultimately, the materials and construction method you choose should align with your priorities.

- If your primary focus is longevity and repairability: Goodyear welt is the gold standard, as its material composition is specifically designed for resoling and a long service life.

- If your primary focus is immediate, out-of-the-box comfort: You might find the initial stiffness of a Goodyear welt a drawback compared to more flexible constructions.

- If your primary focus is a sleek, low-profile look: The inherent bulk from the welt may not align with your aesthetic goals.

Understanding the materials in a Goodyear welt empowers you to recognize true craftsmanship and invest in footwear that is truly built to last.

Summary Table:

| Material | Role in Construction | Key Benefit |

|---|---|---|

| Upper | Main body of the shoe | Aesthetics & Fit |

| Insole | Layer your foot rests on | Direct Comfort |

| Gemming | Canvas rib cemented to insole | Anchor for stitching |

| Welt | Strip stitched to upper & gemming | Enables easy resoling |

| Cork Filling | Fills cavity under foot | Molds to foot for comfort |

| Shank | Metal support under arch | Maintains shoe shape |

| Outsole | Bottom layer contacting ground | Traction & Durability |

Ready to Source Durable, Repairable Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures you receive footwear built with the right materials for superior longevity and performance.

We offer:

- Expert Craftsmanship: Precision Goodyear welt construction for maximum durability.

- Scalable Production: Capabilities to meet the demands of any order size.

- Customization: Tailored solutions for your brand and market.

Let's build footwear that lasts. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance