At its core, the slip resistance of a rubber-soled shoe is determined by three interacting factors: the tread pattern, the rubber compound, and the overall sole design. These elements work together as a system to maintain grip by channeling away liquids and maximizing surface contact.

True slip resistance is not a single feature but an engineered system. The effectiveness of a shoe depends on how its tread disperses contaminants, how its rubber compound conforms to the ground, and how its sole shape prevents hydroplaning.

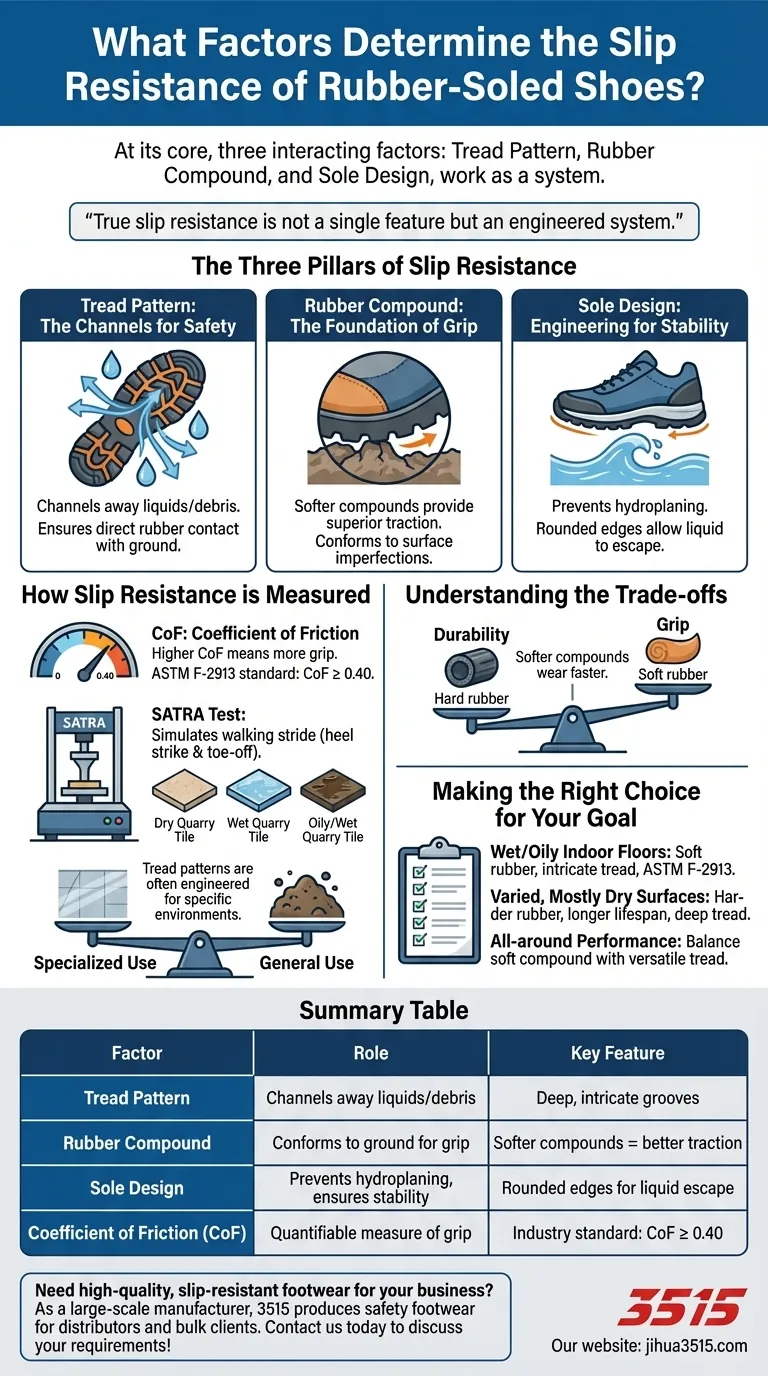

The Three Pillars of Slip Resistance

Understanding how a sole generates grip requires looking at its physical and material properties. Each component plays a distinct role in preventing a fall on a hazardous surface.

Tread Pattern: The Channels for Safety

The grooves and channels on the bottom of a shoe are its first line of defense against slipping.

Deep, intricate tread patterns are designed to channel water, oil, and other debris away from the sole's contact points. By effectively clearing this path, the tread ensures the rubber makes direct contact with the ground, which is essential for generating friction.

Rubber Compound: The Foundation of Grip

The material of the sole itself is arguably the most critical factor.

Softer rubber compounds generally provide superior traction. This is because a softer material can better conform to the microscopic imperfections of a walking surface, creating more surface area contact and a stronger grip.

Sole Design: Engineering for Stability

The overall shape of the sole contributes significantly to its stability, especially on wet surfaces.

Soles with slightly rounded edges can help prevent hydroplaning. As you step, these edges allow liquid to escape from underneath the shoe rather than being trapped, which maintains contact between the sole and the floor.

How Slip Resistance is Measured

While visual inspection is helpful, true slip resistance is a quantifiable, scientific metric. It is not just a marketing term but a standard that can be tested and verified.

The Coefficient of Friction (CoF)

Slip resistance is measured by a value called the coefficient of friction (CoF). In simple terms, a higher CoF means more grip.

A shoe must demonstrate a CoF of at least 0.40 to pass the industry-standard ASTM F-2913 test in the United States and Canada.

Standardized Testing Methods

The most common methodology is the SATRA test. This process mechanically simulates a walking stride, evaluating grip during both the heel strike and the toe-off phases.

Real-World Test Conditions

To ensure reliability, these tests are performed under controlled conditions that mimic common workplace hazards.

Shoes are tested on surfaces like dry quarry tile, wet quarry tile, and oily/wet quarry tile to certify their performance across different scenarios.

Understanding the Trade-offs

Choosing a slip-resistant shoe involves balancing competing factors. No single shoe is perfect for every condition.

Durability vs. Grip

There is often a trade-off between grip and longevity.

The softer rubber compounds that provide the best traction also tend to wear down more quickly than harder, more durable rubber. A shoe designed for maximum safety in a kitchen may not last as long as a work boot for construction sites.

Specialized vs. General Use

Tread patterns are often engineered for specific environments.

A pattern designed to channel water on a smooth floor may be less effective on loose gravel or mud. Understanding your primary walking surface is key to selecting the right tread design.

Making the Right Choice for Your Goal

To select the best shoe, you must align its design features with your most common environmental hazards.

- If your primary focus is safety on wet or oily indoor floors: Look for shoes with soft rubber soles, intricate tread patterns, and an official ASTM F-2913 rating.

- If your primary focus is durability on varied, mostly dry surfaces: You can prioritize a harder rubber compound for a longer lifespan, while still ensuring a deep tread for general traction.

- If your primary focus is all-around performance: Seek a balance between a moderately soft compound and a versatile tread designed to handle both wet and uneven conditions.

By understanding the principles of tread, compound, and design, you can make an informed decision that truly enhances your safety.

Summary Table:

| Factor | Role in Slip Resistance | Key Feature |

|---|---|---|

| Tread Pattern | Channels away liquids/debris | Deep, intricate grooves |

| Rubber Compound | Conforms to ground for grip | Softer compounds provide better traction |

| Sole Design | Prevents hydroplaning, ensures stability | Rounded edges for liquid escape |

| Coefficient of Friction (CoF) | Quantifiable measure of grip | Industry standard: CoF ≥ 0.40 (ASTM F-2913) |

Need high-quality, slip-resistant footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in engineering the perfect balance of tread patterns, rubber compounds, and sole designs ensures your customers get the durable, reliable grip they need.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear