The durability of a military boot is not defined by a single material, but by a strategic system of components working in concert. The most common materials used to achieve this are full-grain leather for the upper, high-density rubber for the outsole, and ballistic nylon for flexible, lightweight panels. These core materials are often enhanced with composite reinforcements and specific construction techniques like double stitching.

True military-grade durability is achieved through a system of materials, not a single one. It relies on the synergy between rugged full-grain leather for structure, lightweight ballistic nylon for flexibility, and specialized rubber compounds for the critical foundation of traction and support.

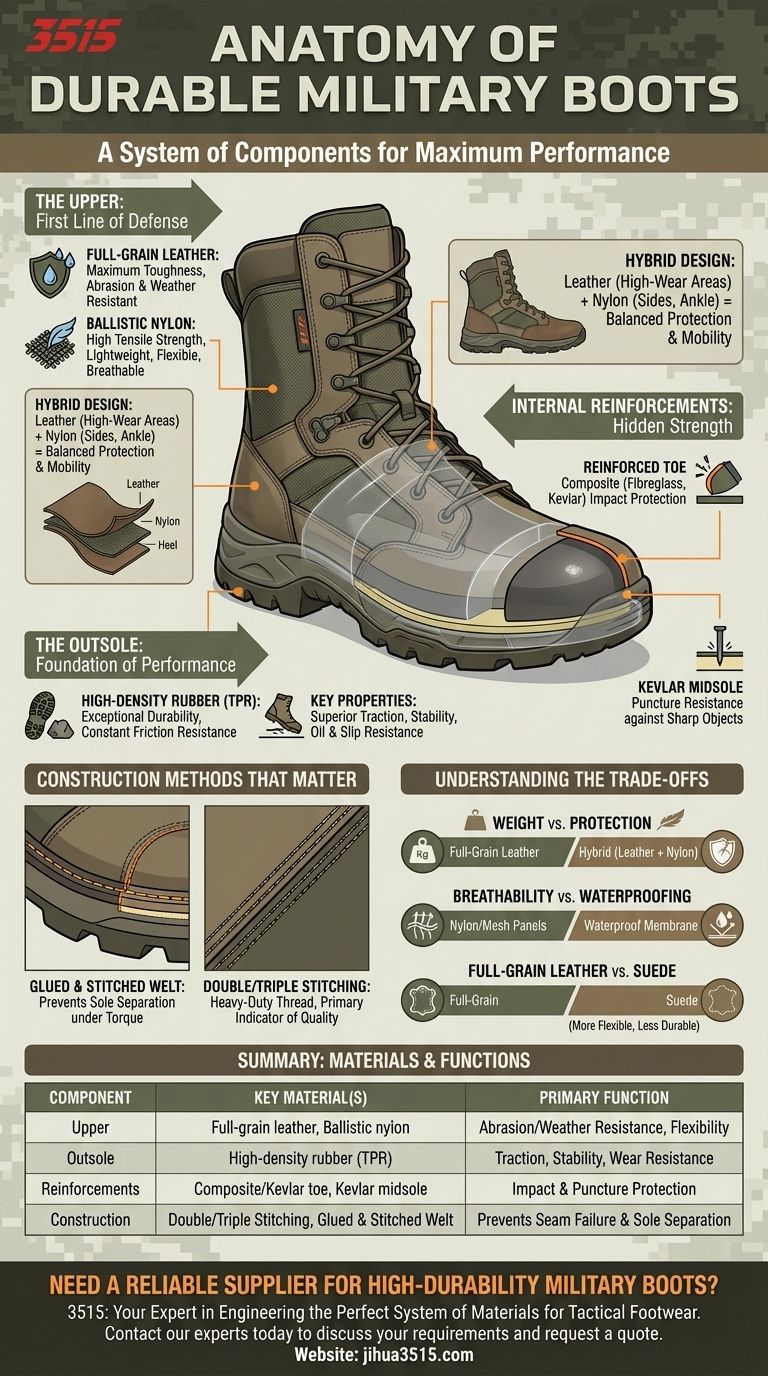

The Anatomy of a Durable Boot: A Component-by-Component Guide

To understand durability, you must look at a boot not as one piece, but as three distinct zones, each requiring different materials to fulfill its function under stress.

The Upper: The First Line of Defense

The upper is the part of the boot that covers the foot and must resist abrasion, tearing, and weather.

Full-grain leather is the traditional standard for maximum toughness. Its dense grain structure provides excellent abrasion protection and natural water resistance.

Ballistic nylon is a synthetic fabric prized for its high tensile strength and resistance to tearing. It is significantly lighter and more breathable than leather, making it ideal for panels in hot-weather or lightweight boots.

Many modern military boots use a hybrid design, combining leather in high-wear areas like the heel and toe with ballistic nylon panels on the sides and ankle for a balance of protection, flexibility, and reduced weight.

The Outsole: The Foundation of Performance

The outsole is the point of contact with the ground and is critical for both longevity and safety.

The most common material is high-density rubber or thermoplastic rubber (TPR). These compounds are engineered for exceptional durability against constant friction.

Key properties include superior traction on varied surfaces, stability, and often resistance to oil and slipping, which is vital in operational environments.

Internal Reinforcements: Hidden Strength

The most critical durability features are often those you cannot see.

Reinforced toe areas are standard, using hardened materials or composites like fibreglass and Kevlar to protect against impact without the weight of traditional steel.

Puncture resistance is often achieved with Kevlar midsoles, a flexible and lightweight material that can stop sharp objects from penetrating the bottom of the boot.

Construction Methods That Matter

The way materials are joined is just as important as the materials themselves.

A truly durable boot will have its outsole both glued and stitched to the upper. This redundant system, known as a Goodyear welt or similar construction, prevents sole separation under extreme torque.

Likewise, look for double or triple stitching with heavy-duty thread throughout the upper, especially where different material panels meet. This is a primary indicator of quality and longevity.

Understanding the Trade-offs

Choosing the right materials always involves balancing competing demands. No single boot is perfect for every scenario.

Weight vs. Protection

A boot made entirely of thick, full-grain leather offers maximum protection but comes with a significant weight penalty that can increase fatigue.

Hybrid leather-and-nylon boots drastically cut weight, improving mobility and comfort, but may offer less raw protection against scrapes and cuts compared to a full leather design.

Breathability vs. Waterproofing

Materials like ballistic nylon and mesh panels are excellent for enhancing airflow, making boots more comfortable in hot and arid environments.

However, achieving true waterproofing requires adding a membrane or liner. While effective at keeping water out, these layers inherently reduce a boot's overall breathability, which can lead to moisture buildup from sweat.

Full-Grain Leather vs. Suede

While both are types of leather, their performance differs dramatically. Full-grain leather is the tough, weather-resistant outer hide.

Suede is made from the softer, inner surface of the hide. It is more comfortable and flexible out of the box but is far more susceptible to water damage, stains, and abrasion.

Making the Right Choice for Your Goal

Your intended environment and mission should dictate the material composition of your boot.

- If your primary focus is maximum durability and harsh-terrain protection: Look for a boot with a predominant full-grain leather upper and a stitched, high-density rubber sole.

- If your primary focus is mobility and use in hot climates: Prioritize boots with a hybrid leather and ballistic nylon upper, featuring mesh panels for enhanced breathability.

- If your primary focus is protection from ground hazards: Ensure the boot specifies a puncture-resistant midsole (like Kevlar) and a reinforced composite toe cap.

Ultimately, the right boot isn't just made of strong materials; it's engineered with the correct system of materials for the task at hand.

Summary Table:

| Component | Key Material(s) | Primary Function |

|---|---|---|

| Upper | Full-grain leather, Ballistic nylon | Abrasion resistance, weather protection, and flexibility |

| Outsole | High-density rubber (TPR) | Traction, stability, and long-term wear resistance |

| Reinforcements | Composite/Kevlar toe, Kevlar midsole | Impact and puncture protection without heavy weight |

| Construction | Double/Triple Stitching, Glued & Stitched Welt | Prevents seam failure and sole separation under stress |

Need a reliable supplier for high-durability military boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical and military footwear for distributors, brand owners, and bulk clients. Our expertise lies in engineering the perfect system of materials—from rugged full-grain leather uppers to puncture-resistant Kevlar midsoles—ensuring your boots meet the highest standards of durability and performance for any environment.

Let us help you equip your team with footwear built to last. Contact our experts today to discuss your specific requirements and request a quote.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- What is the purpose of drainage ports in jungle boots? Essential for Rapid Drying in Wet Environments

- Do military boots need to be waterproofed after every cleaning? Only when water stops beading

- What are some limitations of combat boots? Heavy, Stiff, and Poorly Ventilated

- What factors affect the lifespan of desert boots? A Guide to Maximizing Durability and Comfort

- What are the key features of insulated boots designed for cold weather? A Guide to Warmth, Dryness & Safety

- How should desert boots be laced? Achieve the Perfect, Classic Fit

- Do combat boots require a break-in period? The Essential Guide to Comfort and Safety

- How do combat boots ensure foot protection? The Science Behind Maximum Safety