Yes, a break-in period is essential for most combat boots. Unlike footwear designed for immediate comfort, combat boots are engineered for durability, support, and protection using stiff, robust materials like thick leather and high-density rubber. This initial rigidity requires a gradual process of wear to allow the materials to soften, flex, and mold precisely to the unique shape of your feet, preventing significant discomfort and injury.

The core purpose of breaking in combat boots is not to endure pain, but to systematically transform a rigid piece of protective equipment into a custom-fit tool that supports and protects your feet effectively over the long term.

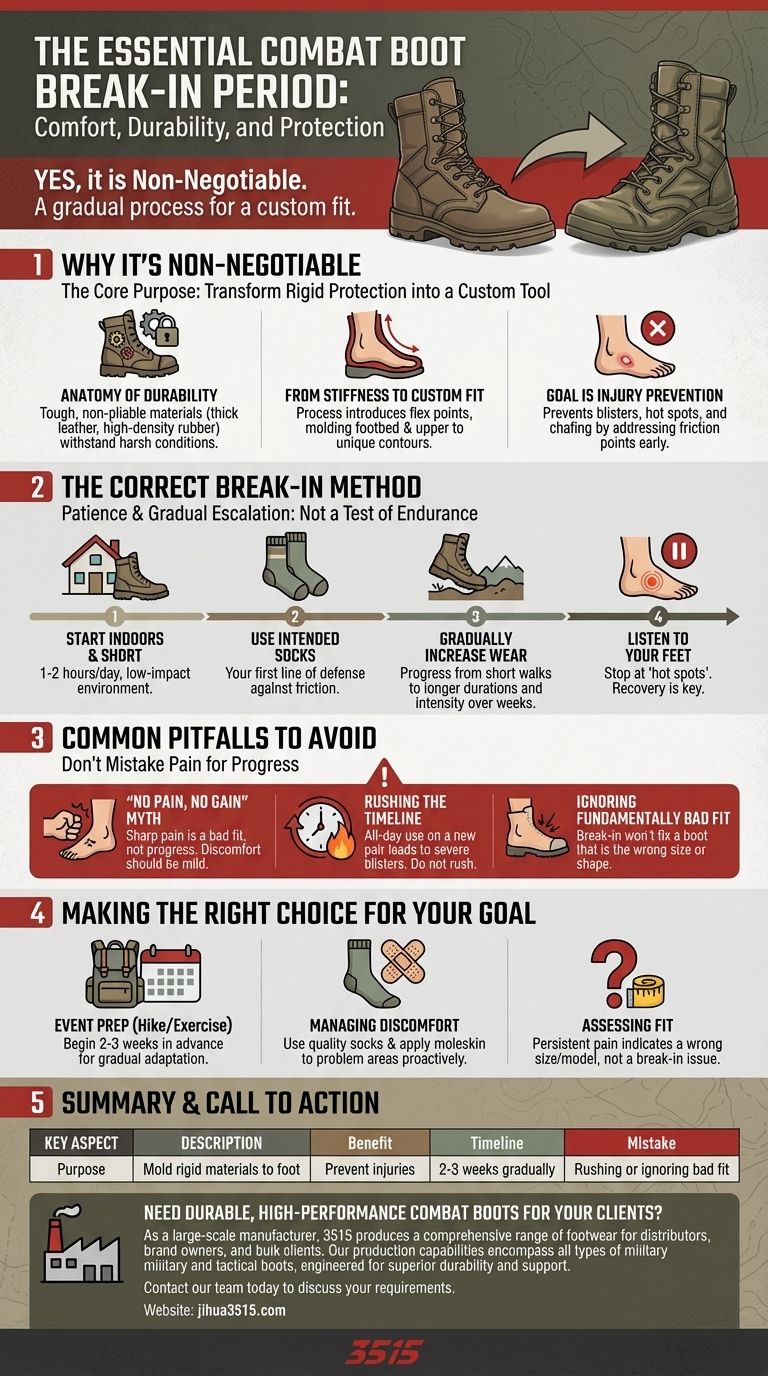

Why a Break-In Period is Non-Negotiable

The necessity for a break-in period is rooted in the fundamental design and materials of a combat boot. Understanding this "why" is the first step to doing it correctly.

The Anatomy of Durability

Combat boots are constructed from tough, non-pliable materials. Full-grain leather, dense nylon fabrics, and stiff soles are chosen for their ability to withstand harsh conditions, not for their out-of-the-box flexibility.

From Stiffness to a Custom Fit

The break-in process gradually introduces flex points into the leather and seams. Over time, the boot's footbed and upper will conform to the specific contours of your arches, ankles, and toes, creating a fit that is uniquely yours.

The Goal is Injury Prevention

Skipping this process and wearing a new pair of stiff boots on a long march or hike is a direct path to painful blisters, hot spots, and chafing. A proper break-in mitigates this by addressing potential friction points before they become a problem.

The Correct Break-In Method

Patience and gradual escalation are the keys to a successful break-in. This is a methodical process, not a test of endurance.

Start Indoors and in Short Bursts

Begin by wearing your new boots around the house for just one to two hours at a time. This allows your feet to begin adapting to the boot in a low-impact environment.

Always Use Your Intended Socks

Wear the same type of thick, moisture-wicking socks you plan to use with the boots in the field. The right sock is your first line of defense against friction and is a critical part of the overall fit.

Gradually Increase Wear Time

Once you can comfortably wear the boots for a few hours indoors, progress to short walks outside on even terrain. Slowly increase the duration and intensity over days and weeks, moving from short walks to longer ones, and eventually to carrying weight or walking on varied terrain.

Listen to Your Feet

Pay close attention to how your feet feel. If you notice a "hot spot"—a pre-blister area of friction or warmth—stop, take the boots off, and let your feet recover. This is a signal to slow down the process.

Common Pitfalls to Avoid

Many common mistakes stem from a misunderstanding of the process, often leading to unnecessary pain and a negative experience.

The "No Pain, No Gain" Myth

Breaking in boots should cause mild discomfort at most, but it should never be truly painful. Sharp, pinching, or stabbing pain is a sign of a poor fit, not a sign that the process is working.

Rushing the Timeline

The most common mistake is trying to break in boots too quickly. Taking a brand-new pair on an all-day hike is a guaranteed recipe for severe blisters and foot pain. This process cannot be rushed.

Ignoring a Fundamentally Bad Fit

A break-in period can make a good-fitting boot feel great, but it cannot fix a bad-fitting boot. If the boot is too short, too narrow, or presses painfully on a part of your foot from the very start, it is likely the wrong size or shape for you.

Making the Right Choice for Your Goal

Your approach should be dictated by your specific needs and timeline. A successful break-in ensures your boots work for you, not against you.

- If your primary focus is preparing for a specific event (like a long hike or field exercise): Begin the break-in process at least two to three weeks in advance to allow for a safe, gradual adaptation without pressure.

- If your primary focus is managing minor discomfort: Ensure you are using high-quality wool or synthetic socks and consider applying moleskin to known problem areas before you even start.

- If your primary focus is assessing fit: Remember that persistent, sharp pain indicates a fundamental fit issue that breaking in will not resolve; you likely need a different size or model.

Investing the time to break in your boots properly is a direct investment in your own future comfort and safety.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | To soften rigid materials and mold the boot to your foot's shape for a custom fit. |

| Key Benefit | Prevents blisters, hot spots, and injuries during extended wear. |

| Recommended Timeline | A gradual process over 2-3 weeks for best results. |

| Common Mistake | Rushing the process or ignoring signs of a poor fit. |

Need durable, high-performance combat boots for your clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military and tactical boots, engineered for superior durability and support from the first step.

Contact our team today to discuss your requirements and discover how our manufacturing expertise can provide the reliable footwear your customers depend on.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How have drain holes been upgraded in modern jungle boots? From Bulky Strainers to Active Water Evacuation

- What is the main focus of the research on 'super boots' for soldiers? Enhancing Soldier Performance & Safety

- What materials are used in the construction of jungle boots? A Guide to Durable, Fast-Drying Footwear

- Can combat boots be repaired if damaged? Extend the Life of Your Rugged Footwear

- What is the purpose of drainage ports in jungle boots? Essential for Rapid Drying in Wet Environments

- What is the purpose of the midfoot area in military boots? It's Your Key to Stability and Blister Prevention.

- Why are combat boots considered versatile footwear? Unmatched Durability for Any Task

- What is the connection between desert boots and South African footwear? From Veldskoen to Global Icon