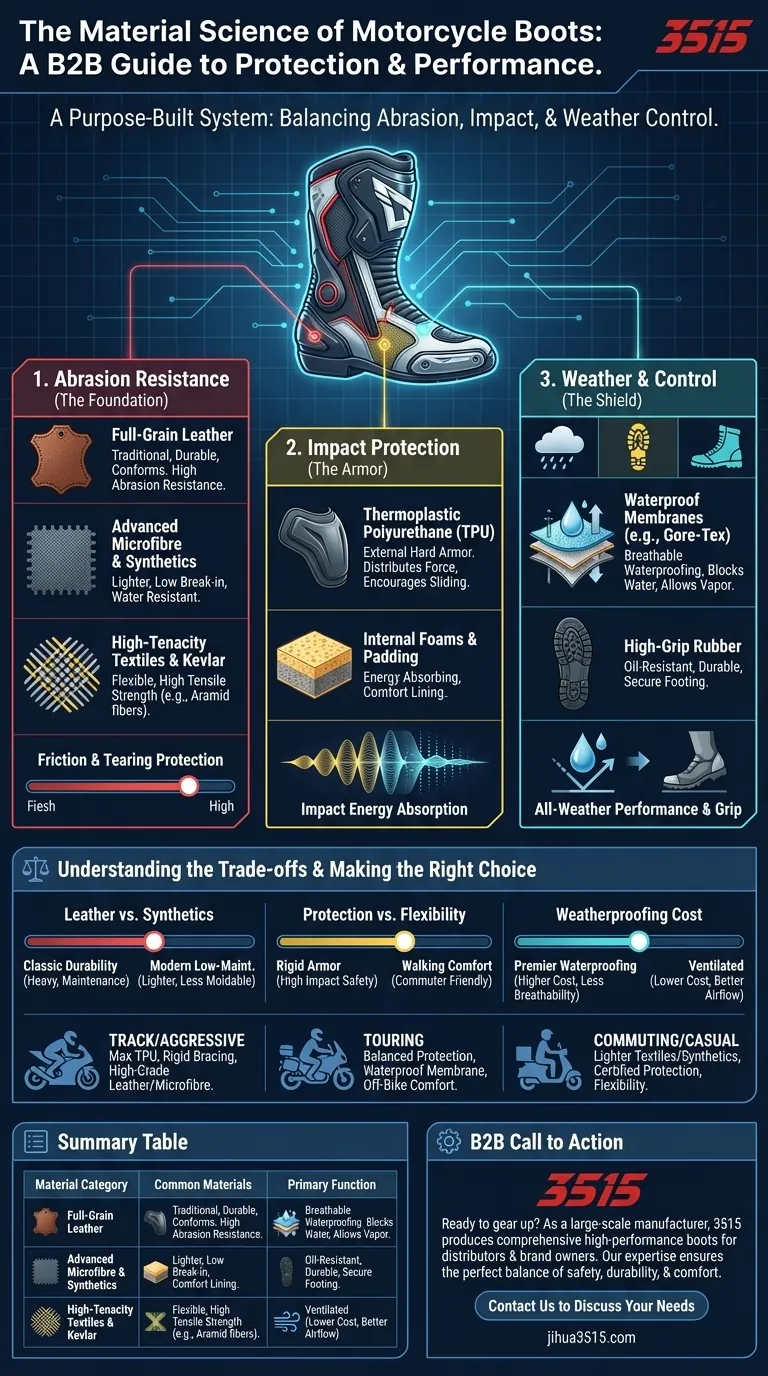

Motorcycle boots are a purpose-built system of materials designed to protect against specific risks. The most common materials used are full-grain leather and advanced synthetics for abrasion resistance, rigid polymers like TPU for impact protection, waterproof yet breathable membranes like Gore-Tex for weather control, and specialized rubber compounds for grip.

The selection of a boot's material is a deliberate engineering choice, balancing the critical needs of abrasion resistance, impact protection, weatherproofing, and rider comfort. Understanding this balance is the key to choosing footwear that truly serves its protective function.

The Foundation: Materials for Abrasion Resistance

The outer shell of the boot, or chassis, is its first line of defense in a slide. The materials used here must withstand intense friction without tearing.

Full-Grain Leather

Leather is the traditional benchmark for motorcycle gear for a reason. It offers exceptional resistance to abrasion, conforms to the wearer's foot over time for a custom fit, and is highly durable.

Advanced Microfibre & Synthetics

Modern synthetic leathers and microfibres are now primary materials in high-performance boots. They offer the abrasion resistance of leather but are often lighter, require less break-in time, and provide better water resistance from the start.

High-Tenacity Textiles & Kevlar

In areas requiring more flexibility, such as accordion panels, manufacturers often use durable textiles. These fabrics can be woven with strands of Kevlar or similar aramid fibers to provide high tensile strength and abrasion resistance in a lightweight, flexible form.

The Armor: Materials for Impact Protection

Sliding is only one risk; impacts with the ground or the motorcycle itself require a different kind of protection. This is where rigid and energy-absorbing materials come into play.

Thermoplastic Polyurethane (TPU)

TPU is a hard, durable plastic used to create the external armor on a boot. You will find it on the shin plate, heel counter, ankle protectors, and toe sliders. Its purpose is to distribute sharp impact forces over a wider area and to provide a low-friction surface that encourages sliding rather than gripping.

Internal Foams and Padding

Lining the interior of the boot and integrated around the ankle and shin are various densities of foam. These materials provide comfort but also serve a critical role in absorbing impact energy that gets past the external TPU armor.

The Shield: Materials for Weather and Control

Effective motorcycle boots must perform in varied conditions and allow for precise control of the bike.

Waterproof Membranes (Gore-Tex)

For touring and all-weather riding, a waterproof and breathable membrane is laminated to the boot's interior. Gore-Tex is the most well-known brand, using a material with pores small enough to block water droplets but large enough to allow sweat vapor to escape.

High-Grip Rubber

The sole of a motorcycle boot is made from a specialized rubber compound. It is engineered to be oil-resistant and highly durable while providing a secure, non-slip grip on the footpegs and on pavement when stopped.

Understanding the Trade-offs

No single material is perfect for every application. Choosing a boot always involves balancing competing priorities.

Leather vs. Synthetics

Leather offers a classic feel and proven durability but requires regular maintenance and can be heavy and hot. Synthetics are low-maintenance and lighter but may not mold to your foot in the same way or last as long as a well-cared-for leather boot.

Protection vs. Flexibility

More external TPU armor provides superior impact protection. However, this rigidity comes at the cost of walking comfort and flexibility, which can be a significant factor for commuters or touring riders.

The Cost of Weatherproofing

A boot with a genuine Gore-Tex membrane offers premier waterproofing. This technology adds a significant cost and can reduce a boot's breathability in hot, dry climates, potentially leading to less comfort than a well-ventilated, non-waterproof option.

Making the Right Choice for Your Riding Style

Your ideal boot material depends entirely on how you ride.

- If your primary focus is track racing or aggressive street riding: Prioritize boots with extensive TPU armor, a rigid ankle-bracing system, and a chassis made from high-grade leather or microfibre.

- If your primary focus is long-distance touring: Look for a balance of certified protection, an effective waterproof membrane like Gore-Tex, and enough flexibility for off-bike comfort.

- If your primary focus is daily commuting or casual riding: Consider lighter boots made from textile or synthetics that offer certified protection (look for CE ratings) with greater flexibility and a more understated style.

Choosing the right materials ensures your boots are not just gear, but a crucial extension of your control and safety on the road.

Summary Table:

| Material Category | Common Materials | Primary Function |

|---|---|---|

| Abrasion Resistance | Full-Grain Leather, Advanced Microfibre, Kevlar Textiles | Protects against friction and tearing in a slide. |

| Impact Protection | Thermoplastic Polyurethane (TPU), Internal Foams | Absorbs and distributes impact energy. |

| Weather & Control | Gore-Tex Membranes, High-Grip Rubber | Provides waterproofing, breathability, and secure footing. |

Ready to gear up with the right protection?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance motorcycle boots for distributors, brand owners, and bulk clients. Our expertise in material science and production ensures your footwear offers the perfect balance of safety, durability, and comfort for any riding style.

Contact us today to discuss your specific needs and discover how we can bring your vision to life.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How does specialized industrial repair and refurbishing equipment contribute to the circular economy for functional footwear? Boost Sustainability & Safety!

- What tests are performed to evaluate shoe breathability? Discover How Your Shoes Keep Your Feet Cool and Dry

- How does a system comprising a closed container and a circulation fan operate during LCHPV disinfection? Ensure Flawless PPE Safety

- Why is it important to consult a coach when choosing show boots? Avoid Costly Mistakes in the Ring

- Why are Teflon cables and specialized ankle straps utilized in treadmill-based trip simulation experiments for footwear testing? Ensure Valid Results.

- Why is it necessary to configure professional footwear for virtual pedestrian testing? Ensure Biomechanical Accuracy

- Why is 100% organic cotton utilized in sustainable footwear? Unlocking Purity for Eco-Conscious Manufacturing

- What technological advancements were introduced in the 2010s? The Decade of Smartphones, Cloud, and AI