To properly maintain leather safety footwear, you must adopt a simple but consistent routine of cleaning, conditioning, and protecting the material. The most critical step is conditioning with a suitable shoe grease, oil, or moisturizing cream to replenish the leather's natural oils, which prevents it from drying out and cracking under stress.

The goal of leather care is not merely cosmetic. It is a fundamental process of preserving the material's core protective qualities—its strength, flexibility, and resistance—ensuring your safety footwear performs as intended for its entire operational lifespan.

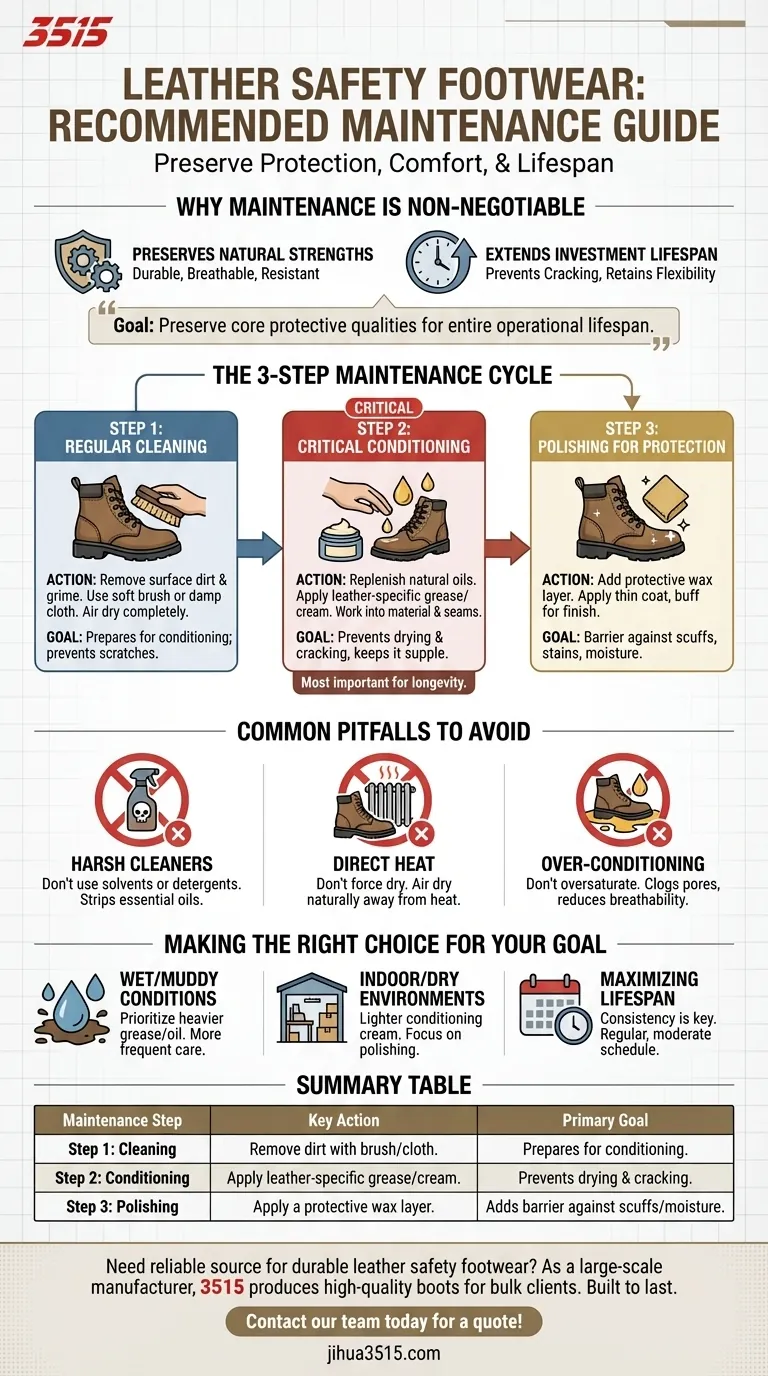

Why Proper Maintenance is Non-Negotiable

Leather is chosen for safety footwear because of its unique combination of natural properties. Without proper care, these inherent advantages quickly degrade, compromising both comfort and safety.

Preserving Leather's Natural Strengths

Leather is naturally durable, breathable, and resistant to many liquids. Its fibrous structure allows water vapor from sweat to escape while providing a barrier against external elements.

This material also serves as an excellent temperature regulator. Proper maintenance ensures these pores don't get clogged with dirt or sealed by cracking, maintaining the footwear's comfort and protective integrity.

Extending the Lifespan of Your Investment

Safety footwear is a critical piece of personal protective equipment and a significant investment. Dirt, moisture, and flexing motions slowly strip the leather of its natural fats and oils.

This loss leads to stiffness, brittleness, and eventually, cracks and splits. A consistent care routine directly counteracts this process, dramatically extending the functional life of your boots.

The Three-Step Maintenance Cycle

A proactive maintenance routine can be broken down into three distinct, easy-to-follow stages. Each step plays a specific role in preserving the leather.

Step 1: Regular Cleaning

Before applying any treatment, you must remove all surface dirt, dust, and grime. Use a soft brush or a damp cloth to wipe the footwear down.

Failing to clean the leather first can trap abrasive particles under the conditioner, which can scratch and damage the material over time. Always allow the leather to air dry completely before moving to the next step.

Step 2: Critical Conditioning

This is the most important step for leather longevity. Conditioning replenishes the oils within the leather, keeping it supple and preventing cracks, especially at flex points.

Apply a leather-specific conditioner, such as a shoe grease, oil, or cream. Work a small amount into the material with a soft cloth, paying special attention to the seams. Always follow the manufacturer's instructions for the specific product you are using.

Step 3: Polishing for Protection

While often seen as a step for appearance, polishing adds a thin layer of protective wax to the surface of the leather.

This wax barrier provides an extra defense against scuffs, stains, and moisture, making future cleaning easier and preserving the finish of the boot.

Common Pitfalls to Avoid

Correctly applying treatments is as important as the treatments themselves. Simple mistakes can inadvertently shorten the lifespan of your footwear.

Using Harsh Cleaners or Solvents

Never use household detergents, solvents, or alcohol-based cleaners on leather. These products are too aggressive and will strip the leather of its essential oils, causing it to dry out almost immediately.

Applying Direct Heat to Dry

If your boots become wet, resist the temptation to place them near a heater, radiator, or open flame. Rapid, direct heat will cook the leather, making it brittle and prone to cracking.

Always let leather footwear air dry naturally at room temperature. Stuffing them with newspaper can help absorb excess moisture and speed up the process safely.

Over-Conditioning the Leather

More is not always better. Applying too much oil or grease can oversaturate the leather, clogging its pores and reducing its natural breathability.

This can lead to the material feeling damp and can also soften it excessively, potentially reducing the structural support of the boot. Follow product instructions and apply thin, even coats.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your specific work environment and goals.

- If your primary focus is working in wet or muddy conditions: Prioritize using a heavier shoe grease or oil to maximize water resistance and perform cleaning and conditioning more frequently.

- If your primary focus is indoor or dry environments: A lighter conditioning cream is sufficient to keep the leather supple, with polishing focused on mitigating scuffs and maintaining a professional appearance.

- If your primary focus is maximizing footwear lifespan: The most important factor is consistency; a regular schedule of cleaning and conditioning is more effective than infrequent, heavy treatments.

A few minutes of dedicated care each week translates directly into months of reliable performance and protection from your investment.

Summary Table:

| Maintenance Step | Key Action | Primary Goal |

|---|---|---|

| Step 1: Cleaning | Remove dirt with a soft brush/damp cloth. | Prepares leather for conditioning; prevents scratches. |

| Step 2: Conditioning | Apply leather-specific grease, oil, or cream. | Replenishes oils to prevent drying and cracking. |

| Step 3: Polishing | Apply a protective wax layer. | Adds a barrier against scuffs, stains, and moisture. |

Need a reliable source for durable leather safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety boots and shoes for distributors, brand owners, and bulk clients. Our expertise ensures your footwear is built to last from the start, making maintenance even more effective. Let's discuss your needs and how we can support your business with superior products. Contact our team today for a quote!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- How do some boots combine materials for better performance? Achieve Superior Safety & Comfort

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit