In simple terms, vulcanization is a chemical process that transforms soft, sticky natural rubber into a strong, durable, and elastic material. It involves heating the rubber with sulfur and other curing agents, which fundamentally changes its molecular structure to make it far more useful for countless applications, from shoe soles to tires.

Vulcanization is the critical step that unlocks the true potential of rubber. It converts the raw, unstable polymer into a stable, strong, and elastic material by creating chemical cross-links between its molecules.

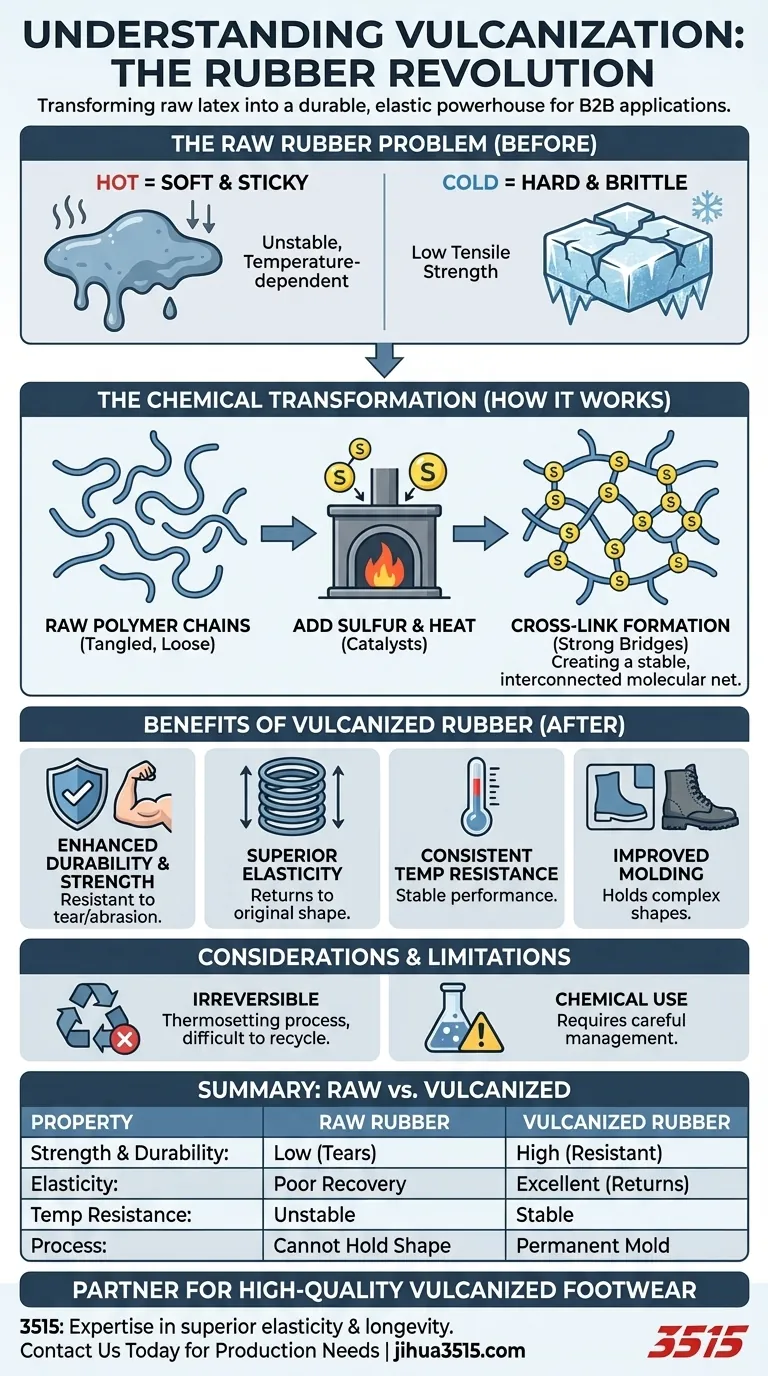

The Problem with Raw Rubber

Before vulcanization, natural rubber, or latex, has limited practical use. Its properties are highly unstable and dependent on temperature.

### Unpredictable Behavior

Raw rubber becomes soft and sticky when it gets warm. Conversely, in cold weather, it turns hard and brittle. This inconsistency makes it unsuitable for products that need to perform reliably in different environments.

### Low Tensile Strength

Without modification, natural rubber is not very strong. It tears easily and cannot withstand significant stress or abrasion, which is why you cannot make a car tire directly from raw latex.

How Vulcanization Works: The Chemical Transformation

The process, discovered by Charles Goodyear, solves these problems by creating a stable molecular network within the rubber.

### The Key Ingredients

The most crucial ingredient added to the rubber is sulfur. The mixture is then subjected to a controlled heating process. This combination of heat and sulfur acts as the catalyst for the chemical change.

### Creating a Molecular Net

During heating, the sulfur atoms form strong chemical bridges, or cross-links, between the long, tangled polymer chains of the rubber. Imagine turning a plate of loose spaghetti strands into a single, interconnected net.

This new molecular structure prevents the polymer chains from moving independently, which is the source of raw rubber's instability. The material is now "cured."

The Benefits of Vulcanized Rubber

This cross-linked structure gives vulcanized rubber a set of highly desirable properties that the raw material lacks.

### Enhanced Durability and Strength

The molecular network makes the rubber significantly stronger and more resistant to tearing and abrasion. This is why it can be used for tough applications like conveyor belts and engine hoses.

### Superior Elasticity

While the cross-links add strength, they are flexible enough to allow the material to stretch and then return to its original shape. This "memory" is the essence of rubber's elasticity.

### Resistance to Temperature Changes

Vulcanized rubber maintains its properties over a much wider temperature range. It no longer becomes sticky when hot or brittle when cold, ensuring consistent performance.

### Reduced Stickiness and Improved Molding

The process eliminates the natural stickiness of raw latex. This makes the rubber easier to handle and allows it to be molded into complex and permanent shapes, such as boots or gaskets, that hold their form after curing.

Understanding the Limitations

While revolutionary, the vulcanization process is not without its trade-offs and considerations.

### Irreversibility and Recycling

Vulcanization is a thermosetting process, meaning it is not reversible. Once the cross-links are formed, they cannot be easily broken down. This makes recycling vulcanized rubber significantly more challenging than recycling thermoplastics.

### Use of Chemicals

The traditional process relies on sulfur and other chemical accelerators. Managing these materials requires careful control to ensure safety and minimize environmental impact during manufacturing.

Applying This Knowledge

Understanding vulcanization is key to appreciating why rubber is such a versatile and essential material in modern industry.

- If your primary focus is material science: Recognize that vulcanization creates a cross-linked polymer network, which is the fundamental reason for rubber's combined strength and elasticity.

- If your primary focus is product design or manufacturing: View vulcanization as the essential curing process that locks in the final shape and performance characteristics of a rubber component.

Ultimately, vulcanization is the invention that transformed a curious natural substance into a cornerstone of the industrial world.

Summary Table:

| Property | Raw Rubber | Vulcanized Rubber |

|---|---|---|

| Strength & Durability | Low, tears easily | High, resistant to abrasion & tearing |

| Elasticity | Poor shape recovery | Excellent, returns to original shape |

| Temperature Resistance | Unstable (sticky when hot, brittle when cold) | Stable performance across a wide range |

| Process | Cannot hold complex shapes | Can be permanently molded into precise shapes |

Ready to source high-quality vulcanized footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable boots and shoes for distributors, brand owners, and bulk clients. Our expertise in vulcanization ensures superior product performance, elasticity, and longevity.

Contact us today to discuss your production needs and leverage our full manufacturing capabilities for all types of shoes and boots.

Visual Guide

Related Products

People Also Ask

- What are the primary uses of vulcanized soles in footwear? Essential for Skate Shoes & Casual Wear

- How do the thermoplastic characteristics of PVC benefit shoe sole manufacturing? Efficiency and Eco-Friendly Solutions

- What are the advantages of using Polyurethane (PU) materials for custom outsoles? Master Research-Grade Footwear Design

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- Why are rubber-soled shoes considered multi-weather footwear? Unlock All-Season Traction & Protection

- What are the most popular materials used for making shoe soles? Choose the Right Material for Durability & Comfort

- What is vulcanization and how does it affect rubber boots? Discover the Secret to Durable, Waterproof Footwear

- What factors determine the choice of materials for shoe soles? A Guide to Durability, Traction & Comfort