In simple terms, vulcanization is a chemical process that uses heat and sulfur to cure raw, sticky natural rubber. For rubber boots, this process transforms flimsy material into a tough, durable, and completely waterproof product by chemically fusing the boot's components into a single, seamless unit.

The critical advantage of vulcanization isn't just making rubber stronger; it's about eliminating glued seams. The process fuses the layers of rubber together, creating a monolithic, waterproof shell that is far more reliable and durable than boots assembled with adhesives.

From Raw Material to Resilient Footwear

To understand why vulcanization is so essential for high-quality rubber boots, you must first understand the limitations of the raw material itself.

The Problem with Natural Rubber

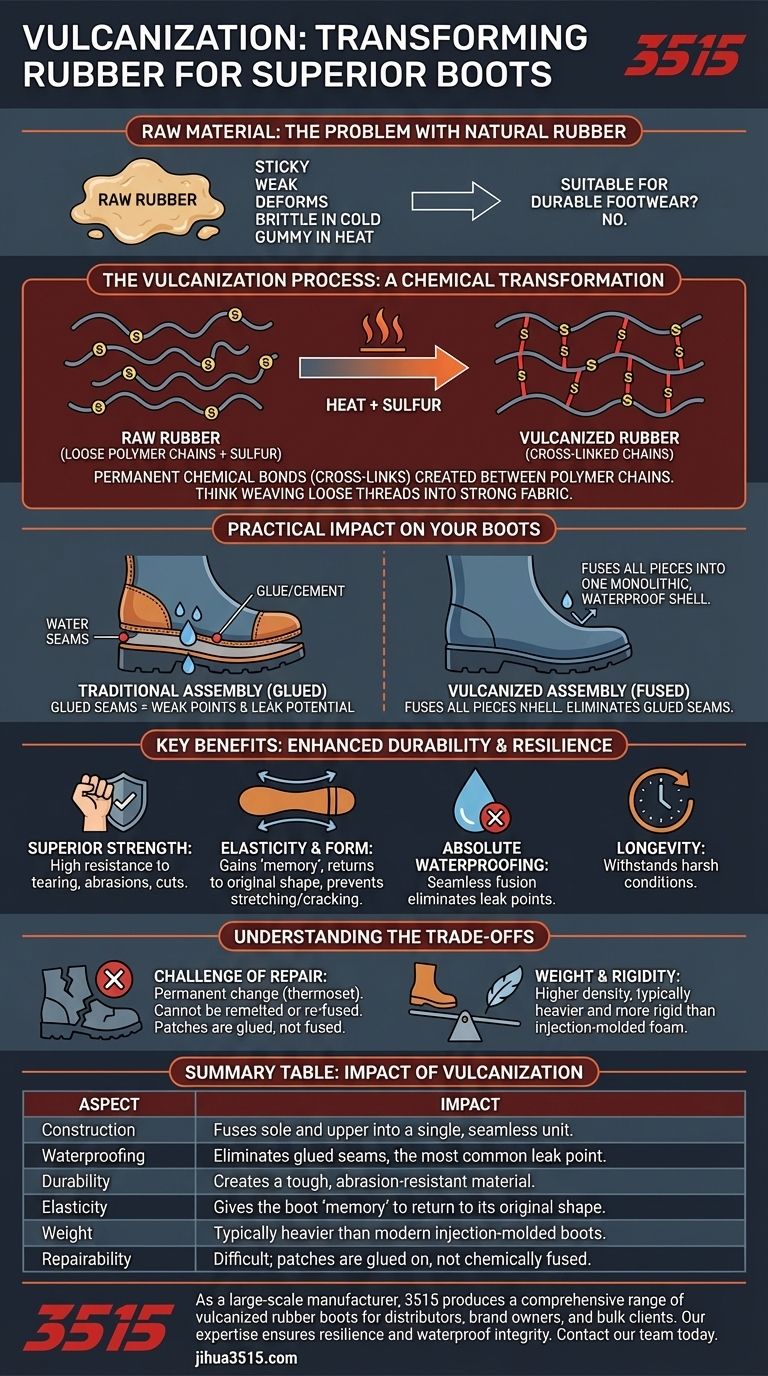

In its raw state, natural rubber is a sticky, weak substance. It deforms easily, becomes brittle in the cold, and turns gummy and soft when it gets hot. It is entirely unsuitable for creating durable footwear.

The Vulcanization Solution: A Chemical Transformation

Vulcanization solves these problems by fundamentally changing the rubber's molecular structure. Sulfur and other curing agents are mixed with the raw rubber. When heat is applied, the sulfur creates strong chemical bonds, or cross-links, between the long polymer chains of the rubber.

Think of raw rubber as a pile of loose threads. Vulcanization is the process that weaves those threads into a single, incredibly strong piece of fabric. This chemical change is permanent and irreversible.

The Practical Impact on Your Boots

This molecular transformation has direct, tangible benefits for the performance and longevity of your rubber boots.

Creating a Single, Fused Unit

During the manufacturing of a vulcanized boot, separate pieces like the sole, upper, and foxing are assembled from uncured rubber. The entire boot is then heated in a mold. This process fuses all the pieces together on a molecular level, eliminating the need for cement or glue at critical seams. The result is a single, leak-proof piece of rubber.

Enhanced Durability and Resilience

The cross-linking makes vulcanized rubber vastly stronger than its raw form. It gains a high resistance to tearing, abrasions, and cuts. This is why these boots can withstand being scraped on rocks or dragged through brush without failing.

Superior Elasticity and Form

A key benefit of this process is that the rubber gains "memory." It can stretch and flex with your foot's movement but will return to its original shape. This prevents the boot from permanently stretching out or cracking over time, maintaining a proper fit and support.

Understanding the Trade-offs

While vulcanization creates an exceptionally durable product, it's important to understand its limitations.

The Challenge of Repair

Because vulcanization is a permanent chemical change (a "thermoset" process), it cannot be undone. You cannot melt the rubber to patch a hole. While you can glue a patch onto the surface, you can never re-fuse the rubber itself, meaning a repair will always be a potential weak point.

Weight and Rigidity

The process that adds so much strength and durability also adds density. Compared to modern alternatives like injection-molded EVA foam boots, traditional vulcanized rubber boots are typically heavier and can feel more rigid.

Making the Right Choice for Your Goal

Understanding the process empowers you to choose the right boot for your specific needs.

- If your primary focus is maximum durability and absolute waterproofing for heavy work or harsh conditions: Vulcanized rubber construction is the benchmark, as its seamless fusion eliminates the most common point of failure—the seams.

- If your primary focus is lightweight comfort for casual use or less demanding activities: You might consider boots made from other materials like EVA foam, which sacrifice some of the ruggedness of vulcanized rubber for a lighter feel.

Ultimately, choosing a vulcanized rubber boot means investing in a proven construction method that prioritizes resilience and waterproof integrity above all else.

Summary Table:

| Aspect | Impact of Vulcanization |

|---|---|

| Construction | Fuses sole and upper into a single, seamless unit |

| Waterproofing | Eliminates glued seams, the most common leak point |

| Durability | Creates a tough, abrasion-resistant material |

| Elasticity | Gives the boot 'memory' to return to its original shape |

| Weight | Typically heavier than modern injection-molded boots |

| Repairability | Difficult; patches are glued on, not chemically fused |

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized rubber boots for distributors, brand owners, and bulk clients. Our expertise in this proven construction method ensures your customers receive footwear built for resilience and absolute waterproof integrity in the toughest conditions. Contact our team today to discuss your specific production needs and discover how we can bring durable, reliable footwear to your market.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do embedded three-dimensional force plates contribute to the analysis of shoe sole design? Expert Gait Engineering

- What are the disadvantages of crepe soles? The Hidden Downsides of Comfort

- Why is Crepe Rubber considered versatile for footwear soles? Lightweight, Flexible & Durable

- What are some key features of outsole molds used in rubber pressing? Essential Guide for Durable Footwear

- What is the primary purpose of implementing a rubber layering process on footwear soles? Enhancing Safety & Stability

- What is the technical significance of using TPU shoe soles in motion recognition? High-SNR Self-Powered Sensing

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- What are the main differences between leather and rubber sole boots? Choose the Right Sole for Your Needs