In short, the choice of shoe sole material is determined by its intended function. Key properties like durability, traction, cushioning, slip resistance, and even specific medical needs dictate which materials are engineered into the final product.

The most critical insight is that a shoe sole is not a single piece, but an engineered system. The final material choice is a carefully calculated compromise between competing demands like performance, comfort, and durability, tailored to the shoe's specific purpose.

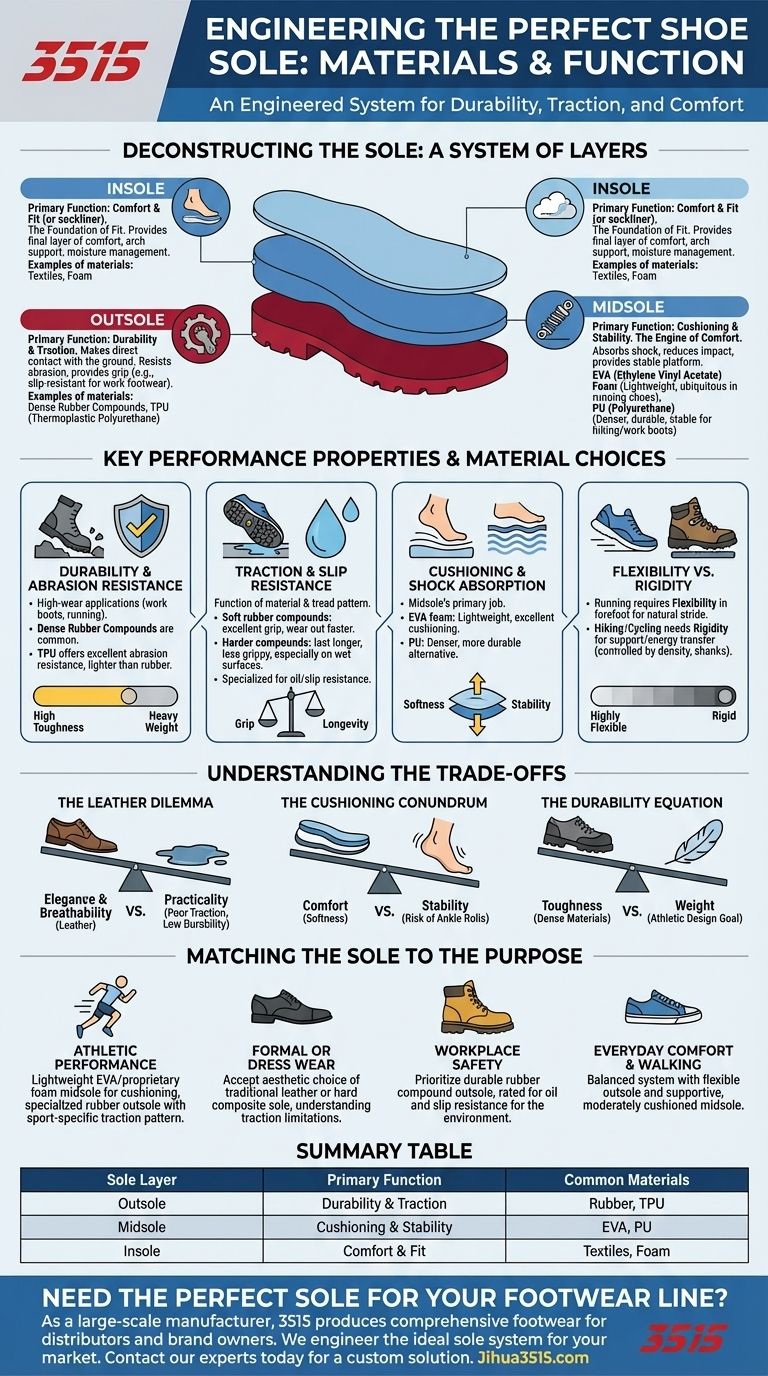

Deconstructing the Sole: A System of Layers

To understand material selection, you must first understand that a modern shoe sole is typically composed of three distinct layers, each with a different job.

The Outsole: Your Contact with the World

The outsole is the bottom-most layer that makes direct contact with the ground. Its material selection is driven primarily by the need for durability and traction.

This layer must resist abrasion from surfaces like concrete and provide the necessary grip to prevent slips, especially in athletic or work footwear.

The Midsole: The Engine of Comfort

The midsole is the crucial layer sandwiched between the outsole and your foot. It is the primary source of cushioning and stability.

Materials here are chosen for their ability to absorb shock, reduce impact on your joints, and provide a stable platform for movement. This is where much of a shoe's "feel" comes from.

The Insole: The Foundation of Fit

The insole (or sockliner) is the removable layer inside the shoe that your foot rests directly on. Its job is to provide a final layer of comfort, support the arch, and help manage moisture.

Key Performance Properties and Material Choices

The functional requirements of a shoe dictate which materials are used for each layer of the sole system.

Durability and Abrasion Resistance

For high-wear applications like work boots or running shoes, dense rubber compounds are a common choice for the outsole. Materials like TPU (Thermoplastic Polyurethane) also offer excellent resistance to abrasion while being lighter than rubber.

Traction and Slip Resistance

Traction is a function of both the material and the tread pattern. Soft rubber compounds offer excellent grip but wear out faster. Harder compounds last longer but can be less grippy, especially on wet surfaces.

For work environments, specialized outsoles are rated for oil and slip resistance.

Cushioning and Shock Absorption

This is the primary job of the midsole. EVA (Ethylene Vinyl Acetate) foam is lightweight and provides excellent cushioning, making it ubiquitous in running shoes. PU (Polyurethane) is a denser, more durable, and stable alternative often found in hiking or work boots.

Flexibility vs. Rigidity

A running shoe requires significant flexibility in the forefoot to allow a natural stride. In contrast, a hiking boot or cycling shoe needs rigidity to provide support and efficient energy transfer. This is controlled by material density and the inclusion of shanks (stiff plates) in the midsole.

Understanding the Trade-offs

There is no single "best" material for a shoe sole. Every choice is a compromise designed to optimize for a specific goal.

The Leather Dilemma: Elegance vs. Practicality

Leather soles, common in high-end dress shoes, offer a classic aesthetic and breathability. However, as noted, they provide poor traction on smooth, wet surfaces and have low durability compared to modern compounds.

The Cushioning Conundrum: Softness vs. Stability

A highly cushioned midsole may feel comfortable, but excessive softness can lead to instability, increasing the risk of ankle rolls. Performance footwear must balance plush cushioning with features that provide stability and control.

The Durability Equation: Toughness vs. Weight

The most durable outsole materials, like dense carbon rubber, are often the heaviest. Athletic shoe designers constantly battle this trade-off, seeking new compounds that can reduce weight without sacrificing longevity.

Matching the Sole to the Purpose

Ultimately, the right sole is the one engineered for your specific activity.

- If your primary focus is athletic performance: Seek a lightweight EVA or proprietary foam midsole for cushioning and a specialized rubber outsole with a traction pattern built for your sport.

- If your primary focus is formal or dress wear: Accept that a traditional leather or hard composite sole is chosen for aesthetics, understanding its limitations in traction.

- If your primary focus is workplace safety: Prioritize an outsole made of a durable rubber compound specifically rated for oil and slip resistance for your environment.

- If your primary focus is everyday comfort and walking: Look for a balanced system with a flexible outsole and a supportive, moderately cushioned midsole.

Choosing the right shoe begins with understanding that its sole is its engineered foundation.

Summary Table:

| Sole Layer | Primary Function | Common Materials |

|---|---|---|

| Outsole | Durability & Traction | Rubber, TPU |

| Midsole | Cushioning & Stability | EVA, PU |

| Insole | Comfort & Fit | Textiles, Foam |

Need the perfect sole for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can engineer the ideal sole system—balancing durability, traction, and comfort—for your specific market.

Contact our experts today to discuss your sole material requirements and get a custom solution.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- What are the limitations of Polyvinyl Chloride (PVC) in slip-resistant shoe soles? Insights for Footwear Safety

- Why is the use of interchangeable rubber sliders necessary? Ensure Footwear Safety with Accurate Slip Resistance Data

- How does natural rubber enhance comfort and flexibility in footwear? Discover the Ultimate Footwear Material

- What are the disadvantages of rubber soles? Understanding the Breathability and Style Trade-Offs

- How does curvature-based weighted sampling address technical challenges in robotic trajectory extraction for shoe soles?

- Why is a constant temperature drying oven necessary? Ensure Quality in Nano-Modified Rubber Production

- How does the execution of a 44-point trajectory by a robot arm ensure high-quality shoe sole gluing? 1.2mm Precision

- Why is hydrophobic pourable liquid silicone rubber preferred for the preparation of footwear outsole molds?