At its core, the most popular materials for shoe soles are rubber and a family of synthetic polymers, including polyurethane (PU) and EVA foam. While traditional leather still holds its place in formal footwear, these modern materials dominate the market due to their versatility, durability, and specific performance characteristics.

The choice of a shoe sole material is not arbitrary; it is a critical engineering decision that balances the fundamental trade-offs between durability, grip, weight, and comfort. There is no single "best" material, only the most appropriate one for the shoe's intended purpose.

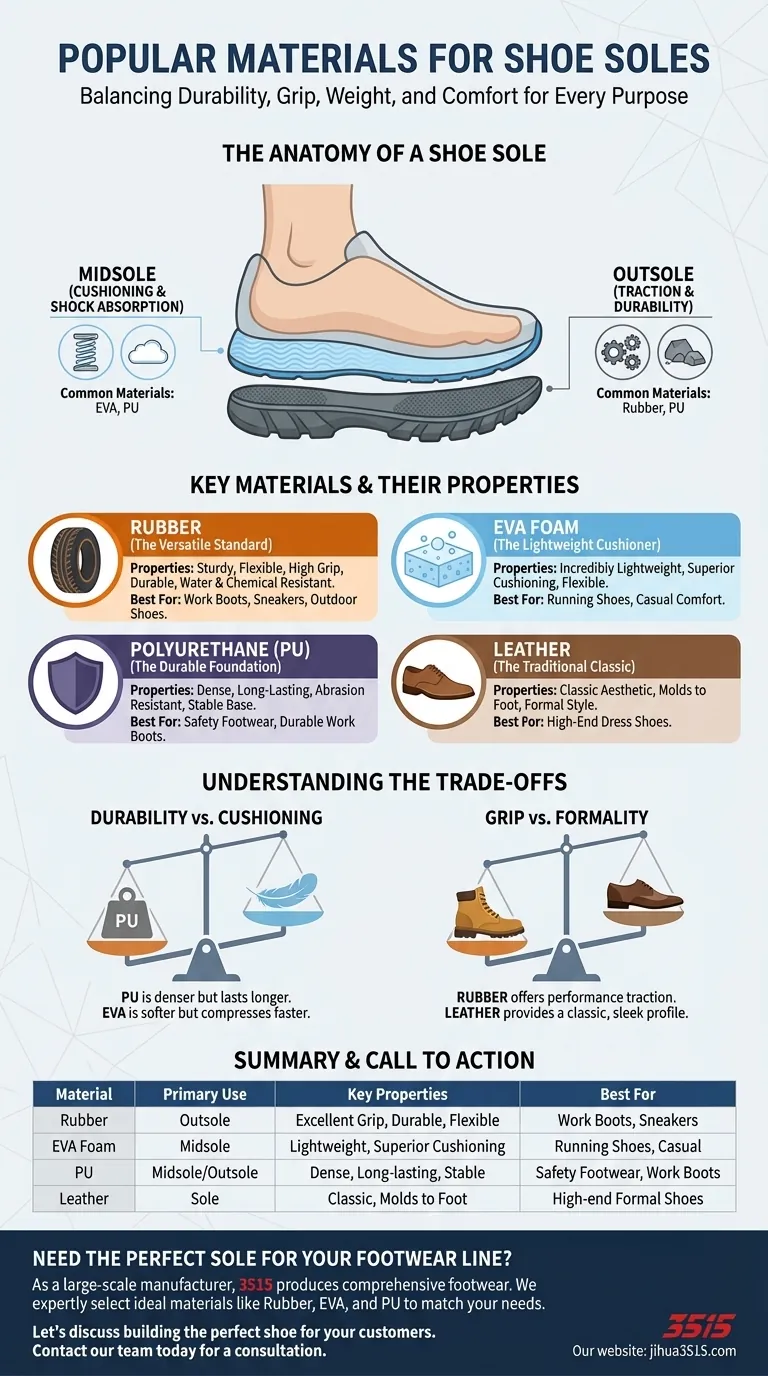

The Anatomy of a Shoe Sole: More Than One Layer

To understand sole materials, it's crucial to recognize that a modern sole is often a system of layers, primarily the midsole and the outsole.

The Midsole: The Hidden Comfort Engine

The midsole is the layer between your foot and the outsole. Its primary job is shock absorption and cushioning.

The most common material here is Ethylene-Vinyl Acetate (EVA). It is a lightweight, flexible foam that provides excellent cushioning, making it a favorite for athletic and walking shoes.

A denser alternative is Polyurethane (PU), which offers more durable, long-lasting support, though it is typically heavier than EVA.

The Outsole: Your Connection to the Ground

The outsole is the part that makes direct contact with the ground. Its function is to provide traction (grip) and durability.

Rubber is the undisputed workhorse for outsoles. Its natural flexibility, high resistance to wear, and excellent grip make it ideal for everything from casual sneakers to heavy-duty work boots.

Polyurethane (PU) is also frequently used for outsoles, prized for its exceptional durability and slip resistance, making it a common choice for safety and work footwear.

A Breakdown of Key Materials

Each popular material offers a distinct set of properties tailored to different types of footwear.

Rubber: The Versatile Standard

Rubber is popular because it is sturdy, waterproof, and highly flexible. This allows manufacturers to mold it into complex tread patterns for superior grip without sacrificing comfort. It effectively absorbs shock and is resistant to heat and many chemicals.

Polyurethane (PU): The Durable Foundation

PU is known for its toughness and longevity. As a sole material, it is denser and more resistant to wear and abrasion than other synthetics, providing a stable and protective base. This makes it a go-to for shoes that need to withstand harsh conditions.

EVA: The Lightweight Cushioner

EVA's primary advantage is its incredibly low weight combined with excellent cushioning properties. This makes it the dominant material for the midsoles of running shoes and comfortable everyday footwear, as it reduces pressure and fatigue on the feet.

Leather: The Traditional Classic

Leather is the original sole material, primarily used today for high-end dress shoes. It offers a classic aesthetic and can mold to the wearer's foot over time. However, its primary function is style rather than pure performance.

Understanding the Trade-offs

Choosing a sole material always involves balancing competing priorities.

Durability vs. Cushioning

There is often an inverse relationship between these two factors. Denser materials like Polyurethane last longer but can feel stiff. Lighter foams like EVA provide superior cushioning but will compress and wear out more quickly.

Grip vs. Formality

Materials engineered for maximum grip, like rubber with deep treads, are essential for performance and safety but are ill-suited for formal wear. Leather soles offer a sleek, traditional profile but provide poor traction on smooth, wet surfaces.

Cost and Complexity

A simple, single-material sole is cost-effective. However, high-performance footwear often combines materials—for instance, a cushioned EVA midsole bonded to a durable rubber outsole—to get the best of both worlds, though this increases manufacturing complexity and cost.

Choosing the Right Sole for Your Purpose

Your activity should dictate your choice of sole material.

- If your primary focus is everyday comfort and walking: Look for shoes with a lightweight EVA midsole for cushioning and a flexible rubber outsole for reliable grip.

- If your primary focus is durability and workplace safety: Prioritize outsoles made from dense rubber or Polyurethane (PU) for their superior resistance to wear, oil, and slips.

- If your primary focus is formal style for office or event wear: Classic leather soles are the standard, offering a timeless look, but be mindful of their limited traction.

Understanding the material under your feet empowers you to select footwear that truly performs for your specific needs.

Summary Table:

| Material | Primary Use | Key Properties | Best For |

|---|---|---|---|

| Rubber | Outsole | Excellent grip, durable, flexible | Work boots, casual sneakers, outdoor shoes |

| EVA Foam | Midsole | Lightweight, superior cushioning | Running shoes, comfortable everyday footwear |

| Polyurethane (PU) | Midsole/Outsole | Dense, long-lasting, stable | Safety footwear, durable work boots |

| Leather | Sole | Classic, molds to foot | High-end formal dress shoes |

Need the perfect sole for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to expertly select and work with the ideal sole material—be it durable rubber, lightweight EVA, or tough PU—to match your specific market needs and performance requirements.

Let's discuss how we can build the perfect shoe for your customers. Contact our team today for a consultation.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Breathable Perforated Slip-On Loafers Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility

- What are the main materials used in the production of rain boots? A Guide to Durability & Comfort