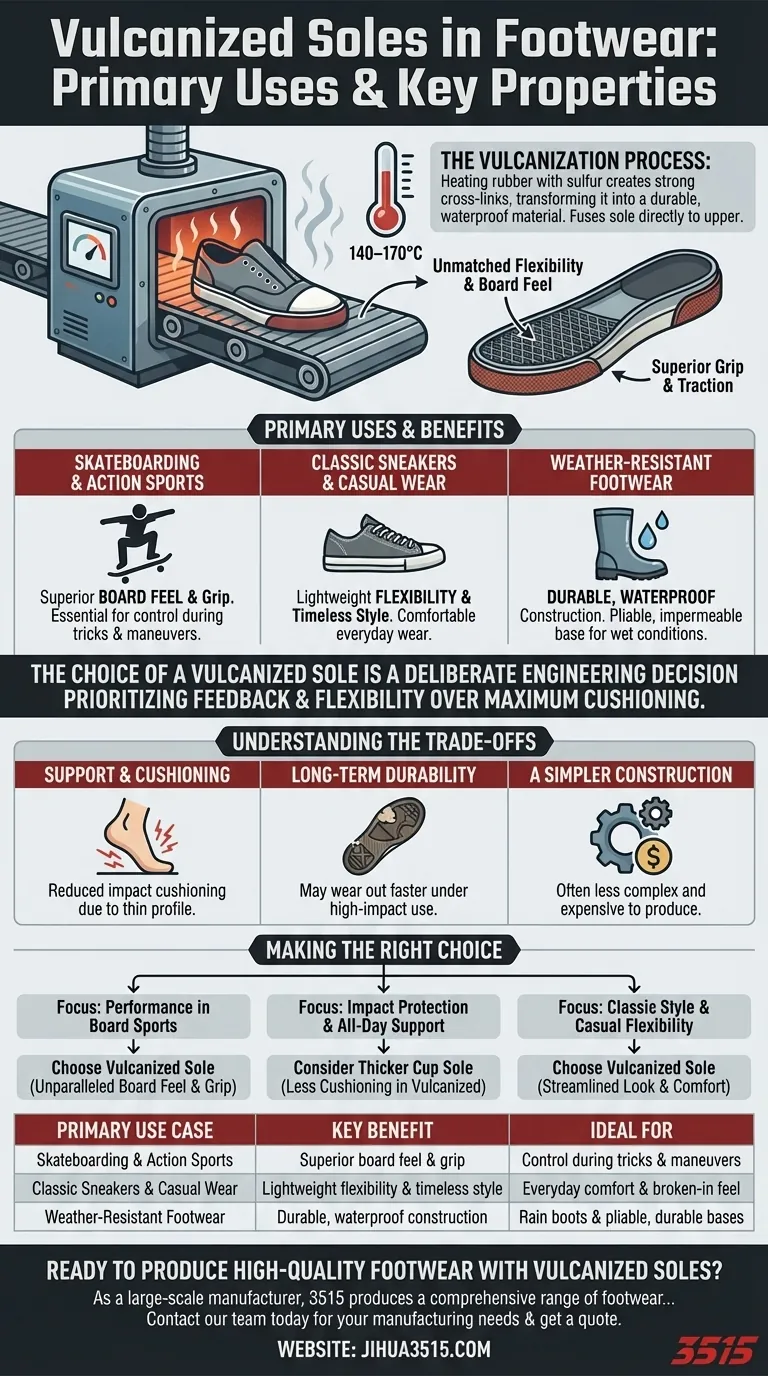

At its core, a vulcanized sole is primarily used for footwear where exceptional flexibility, grip, and tactile ground-feel are critical. This makes it the standard construction for performance skate shoes, classic canvas sneakers, and certain types of weather-resistant boots that require a pliable, durable base.

The choice of a vulcanized sole is a deliberate engineering decision that prioritizes feedback and flexibility over maximum cushioning. It connects the wearer to the surface beneath them in a way thicker, more rigid soles cannot.

The Defining Characteristics of a Vulcanized Sole

To understand its uses, you must first understand the unique properties that result from its creation. The vulcanization process fundamentally alters the molecular structure of rubber, giving it its signature characteristics.

The Vulcanization Process: Forging Strength

The process involves heating natural rubber with sulfur and other agents to temperatures between 140–170°C. This forges strong cross-links between the rubber polymers, transforming a soft, sticky substance into a far more durable, waterproof, and resilient material.

During footwear production, an entire shoe is placed on a heated aluminum last, which bakes the rubber components together, fusing the sole directly to the shoe's upper.

Unmatched Flexibility and "Board Feel"

Vulcanized soles are characteristically thin and highly flexible. This construction allows the sole to bend easily with the foot, providing a broken-in feel almost immediately.

For activities like skateboarding, this translates to superior board feel—the ability to feel the board's contours and position through the shoe, which is essential for control during tricks.

Superior Grip and Traction

The chemical curing process results in a rubber that offers an excellent, tacky grip. This makes it ideal for sports footwear used on smooth surfaces, like a skateboard deck or a basketball court, where quick, precise movements demand reliable traction.

Where Vulcanized Soles Excel

The specific properties of vulcanized rubber make it the optimal choice for several distinct footwear categories.

Skateboarding and Action Sports

This is the quintessential use case for vulcanized soles. The combination of board feel, flexibility, and grip gives skateboarders the control and feedback they need for complex maneuvers and rail tricks.

Classic Sneakers and Casual Wear

Iconic canvas shoes almost universally use vulcanized soles. The simple, streamlined construction results in a lightweight shoe that is comfortable for everyday wear and valued for its timeless aesthetic.

Weather-Resistant Footwear

The vulcanization process creates a waterproof and weather-resistant material. This makes it a natural choice for footwear like rain boots, where a durable, flexible, and impermeable sole is essential.

Understanding the Trade-offs

No single construction method is perfect for every application. The benefits of vulcanized soles come with specific compromises.

Support and Cushioning

The primary trade-off for excellent board feel is a reduction in foot support and impact cushioning. Because the sole is thin, it offers less protection from hard landings compared to thicker, more complex soles like cup soles.

Long-Term Durability

While the rubber itself is durable, the thin profile and simple construction can cause vulcanized shoes to wear out faster than their more robust counterparts, especially under heavy, high-impact use.

A Simpler Construction

The construction method is less complex than assembling a cup sole, which often makes vulcanized shoes less expensive to produce and purchase.

Making the Right Choice for Your Needs

Selecting the right sole construction depends entirely on your intended use and priorities.

- If your primary focus is performance in board sports: A vulcanized sole is the superior choice for its unparalleled board feel and grip.

- If your primary focus is impact protection and all-day support: You should consider footwear with a thicker cup sole, as vulcanized construction offers less cushioning.

- If your primary focus is classic style and casual flexibility: The streamlined look and comfortable feel of vulcanized shoes make them an excellent and timeless option.

Ultimately, understanding the properties of a vulcanized sole allows you to choose your footwear as a precise tool for your specific activity.

Summary Table:

| Primary Use Case | Key Benefit | Ideal For |

|---|---|---|

| Skateboarding & Action Sports | Superior board feel & grip | Control during tricks & maneuvers |

| Classic Sneakers & Casual Wear | Lightweight flexibility & timeless style | Everyday comfort and a broken-in feel |

| Weather-Resistant Footwear | Durable, waterproof construction | Rain boots and pliable, durable bases |

Ready to produce high-quality footwear with vulcanized soles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including performance skate shoes, classic sneakers, and weather-resistant boots built with durable vulcanized soles.

We can help you leverage the benefits of vulcanization—like unmatched flexibility and superior grip—to create the perfect product for your market. Contact our team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear