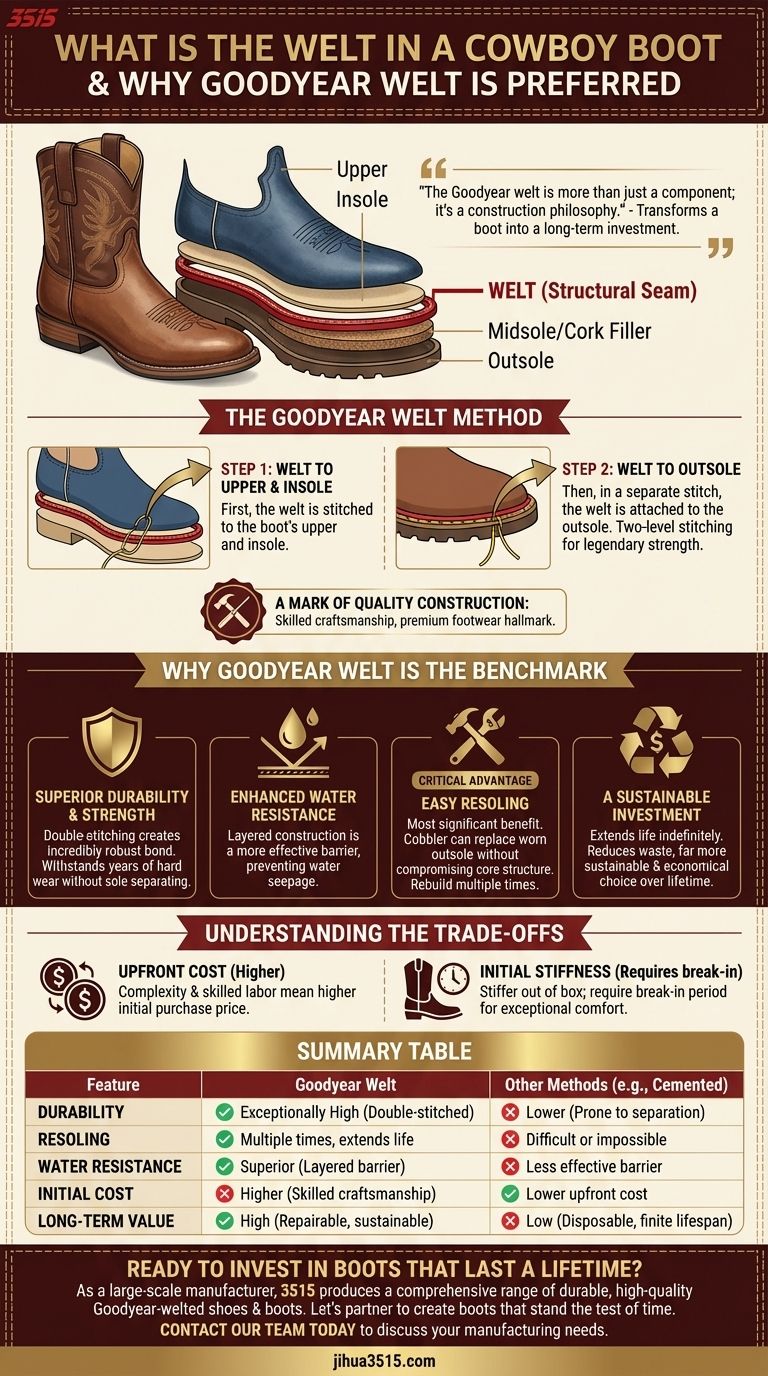

At its core, the welt of a cowboy boot is the structural seam that attaches the sole to the upper part of the boot. While other methods exist, the Goodyear welt is overwhelmingly preferred because it creates a boot that is exceptionally durable, water-resistant, supportive, and, most importantly, can be resoled multiple times, vastly extending its life.

The Goodyear welt is more than just a component; it's a construction philosophy. It transforms a boot from a disposable item into a long-term, repairable investment designed to last for decades.

Understanding the Welt's Function

A boot's construction method is one of the most critical factors determining its quality and lifespan. The welt is the lynchpin of this entire system.

The Role of the Welt

The welt is a strip of leather, roughly half an inch wide, that is stitched around the bottom edge of the boot's upper.

It acts as the crucial intermediary, connecting the upper (the part covering your foot) to the outsole (the part that hits the ground).

The Goodyear Welt Method

The Goodyear welt process, patented by Charles Goodyear Jr. in 1871, involves two independent stitches.

First, the welt is stitched to the boot's upper and insole. Then, in a separate stitch, the welt is attached to the outsole. This two-level stitching is the source of its legendary strength.

A Mark of Quality Construction

This method is more labor-intensive and requires skilled craftsmanship, which is why it's a hallmark of high-quality, premium footwear.

Why the Goodyear Welt is the Benchmark

The benefits of the Goodyear welt directly address the core requirements of a dependable boot: durability, longevity, and performance.

Superior Durability and Strength

The double-stitching process creates an incredibly robust and secure bond between the sole and the rest of the boot. This construction can withstand years of hard wear without the sole separating.

Enhanced Water Resistance

The Goodyear welt creates a more effective barrier between the insole and the outsole. This layered construction makes it significantly harder for water from the ground to seep into the boot.

The Critical Advantage: Easy Resoling

This is the most significant benefit. Since the outsole is stitched to the welt and not directly to the upper, a cobbler can easily cut the old stitches and attach a new sole.

This process can be repeated multiple times without compromising the boot's core structure, allowing you to effectively rebuild your boots for a fraction of the cost of a new pair.

A Sustainable Investment

The ability to resole a boot extends its life indefinitely. This reduces waste and makes a Goodyear-welted boot a far more sustainable and economical choice over its lifetime.

Understanding the Trade-offs

While the Goodyear welt is the gold standard, it's important to understand the complete picture.

The Upfront Cost

The complexity and skilled labor required for a Goodyear welt mean that boots with this construction have a higher initial purchase price.

Initial Stiffness

Goodyear-welted boots are often stiffer out of the box compared to boots with cemented soles. They typically require a break-in period to conform to your foot, after which they become exceptionally comfortable.

Making the Right Choice for Your Boots

Your decision should be based on what you value most in your footwear.

- If your primary focus is longevity and lifetime value: The Goodyear welt is the only choice. It is the defining feature of a boot that is built to be repaired, not replaced.

- If your primary focus is the lowest possible price for occasional use: A boot with a cemented sole may be sufficient, but you must accept that it cannot be effectively resoled and has a finite lifespan.

Ultimately, choosing a boot with a Goodyear welt is an investment in craftsmanship that pays dividends in durability and sustainability for years to come.

Summary Table:

| Feature | Goodyear Welt | Other Methods (e.g., Cemented) |

|---|---|---|

| Durability | Exceptionally high; double-stitched for strength | Lower; prone to sole separation |

| Resoling | Can be resoled multiple times, extending boot life | Difficult or impossible to resole effectively |

| Water Resistance | Superior; layered construction prevents seepage | Less effective barrier |

| Initial Cost | Higher due to skilled craftsmanship | Lower upfront cost |

| Long-Term Value | High; a repairable, sustainable investment | Low; disposable, finite lifespan |

Ready to Invest in Boots That Last a Lifetime?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of Goodyear-welted shoes and boots, ensuring your customers receive products built for superior durability, easy resoling, and long-term value.

Let’s partner to create boots that stand the test of time. Contact our team today to discuss your manufacturing needs and how we can bring reliability and craftsmanship to your product line.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- Why are heavy duty work boots important in high-risk environments? Essential PPE for Ultimate Safety

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- What is the difference between soft toe and safety-toe? Choose the Right Toe Protection for Your Job

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety