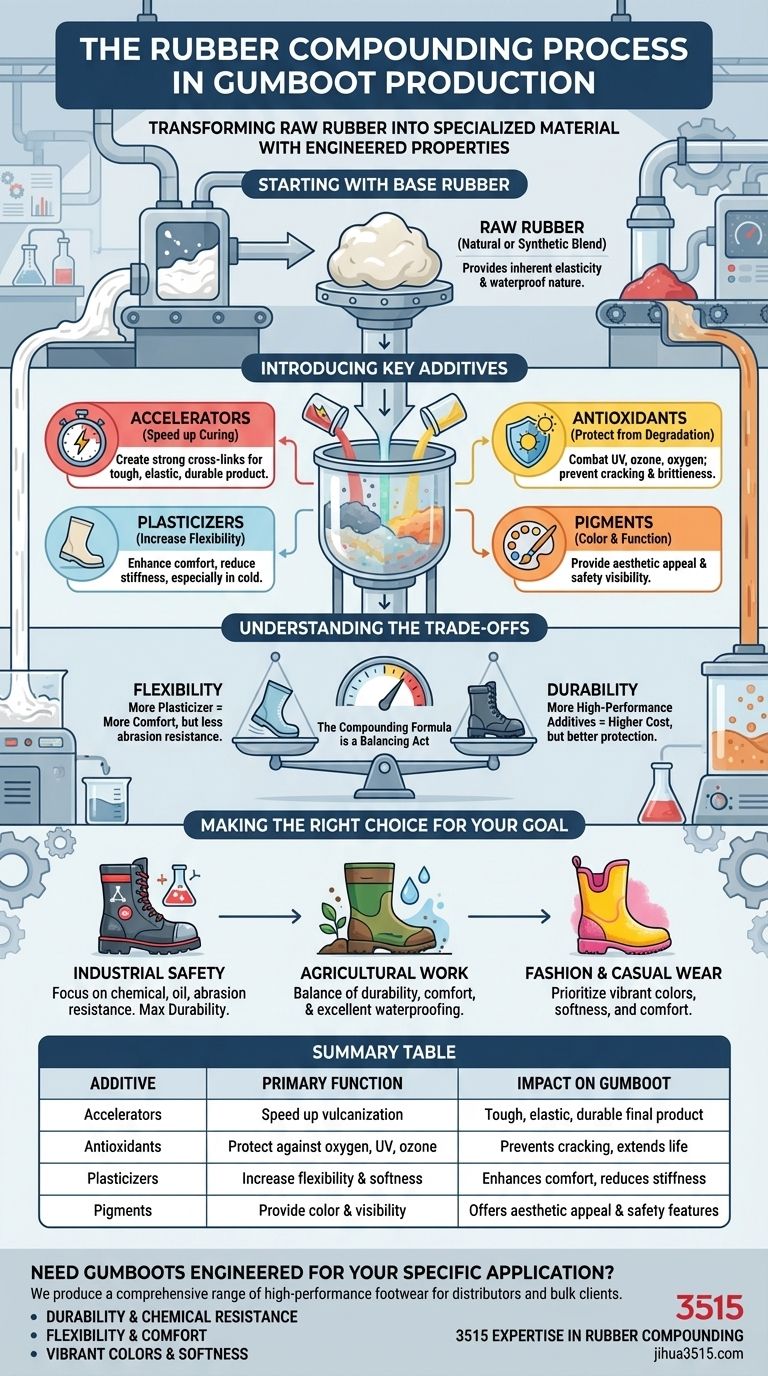

The primary purpose of rubber compounding in gumboot production is to transform raw rubber into a specialized material with specific, engineered properties. This process involves precisely blending the base rubber with a variety of additives to control the final boot's durability, flexibility, color, and resistance to environmental factors.

The core takeaway is that compounding is not just an optional step; it is the fundamental process that determines a gumboot's performance and suitability for its intended purpose, whether for heavy industry, agriculture, or daily wear.

The Role of Compounding in Material Engineering

Raw natural or synthetic rubber lacks the necessary properties for a durable and functional product like a gumboot. Compounding is the material science that turns this base polymer into a high-performance material.

Starting with the Base Rubber

The foundation of any gumboot is the rubber itself, which can be natural or a synthetic blend. This base material provides the inherent elasticity and waterproof nature of the boot.

Introducing Key Additives

The "magic" happens when specific additives are mixed into the rubber in a process called compounding. Each ingredient has a distinct role in modifying the final material.

Accelerators for Curing

Accelerators are chemicals that speed up the vulcanization (curing) process. This crucial step creates strong cross-links between rubber molecules, transforming the soft, sticky raw material into a tough, elastic, and durable final product.

Antioxidants for Longevity

Antioxidants and antiozonants are added to protect the rubber from degradation. They combat the damaging effects of oxygen, UV radiation from sunlight, and ozone, preventing the boots from becoming brittle and cracked over time.

Plasticizers for Flexibility

Plasticizers are substances that increase the flexibility and softness of the rubber compound. This makes the gumboots more comfortable to wear and walk in, reducing stiffness, especially in cold temperatures.

Pigments for Aesthetics and Function

Color pigments provide the final color of the gumboot. Beyond simple aesthetics for fashion purposes, specific colors can also serve as safety indicators in industrial environments (e.g., bright yellow or orange for high visibility).

Understanding the Trade-offs

The compounding formula is a balancing act. Adjusting the "recipe" to enhance one property can often compromise another, creating critical trade-offs.

Flexibility vs. Durability

Increasing the amount of plasticizer makes a boot more flexible and comfortable. However, an excess can potentially reduce the material's overall abrasion and chemical resistance, making it less suitable for harsh industrial settings.

Cost vs. Performance

High-performance additives, such as advanced antioxidants or specialized chemical-resistant fillers, significantly increase the final cost of the gumboot. Manufacturers must balance the desired performance characteristics with the target price point for the intended market.

Making the Right Choice for Your Goal

Understanding the basics of compounding empowers you to select a boot that is truly fit for its purpose.

- If your primary focus is industrial safety: Look for boots specified with high resistance to chemicals, oils, and abrasion, indicating a compound engineered for maximum durability.

- If your primary focus is agricultural work: You need a balance of durability, flexibility for all-day comfort, and excellent waterproofing, which comes from a well-formulated compound using quality plasticizers and antioxidants.

- If your primary focus is fashion or casual wear: The compound will likely prioritize vibrant color pigments and a higher level of plasticizers for a softer, more comfortable feel over extreme durability.

Ultimately, the compounding process is what ensures your gumboot is not just a piece of rubber, but a precisely engineered tool for your specific needs.

Summary Table:

| Additive | Primary Function | Impact on Gumboot |

|---|---|---|

| Accelerators | Speed up vulcanization (curing) | Creates a tough, elastic, and durable final product. |

| Antioxidants | Protect against oxygen, UV, and ozone | Prevents cracking and brittleness, extending boot life. |

| Plasticizers | Increase flexibility and softness | Enhances comfort and reduces stiffness, especially in cold weather. |

| Pigments | Provide color and visibility | Offers aesthetic appeal and safety features for different work environments. |

Need Gumboots Engineered for Your Specific Application?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our expertise in rubber compounding allows us to precisely engineer gumboots for any need—from heavy-duty industrial safety to comfortable agricultural work and vibrant fashion lines.

We ensure your boots are built to last with the right balance of:

- Durability & Chemical Resistance for industrial settings.

- Flexibility & Comfort for all-day wear in agriculture.

- Vibrant Colors & Softness for the fashion and casual markets.

Let us create the perfect gumboot for your customers. Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?