The primary purpose of puncture-resistant footwear is to protect your feet from being pierced by sharp objects you might step on from below. This specialized safety gear is engineered with a protective plate inside the sole to act as a shield against hazards like nails, screws, broken glass, and scrap metal.

The core function is straightforward: prevent injury by stopping sharp objects from penetrating the bottom of the boot. This is achieved not by a thick outsole, but by a dedicated, resilient plate embedded within the boot's midsole, serving as a critical last line of defense in hazardous environments.

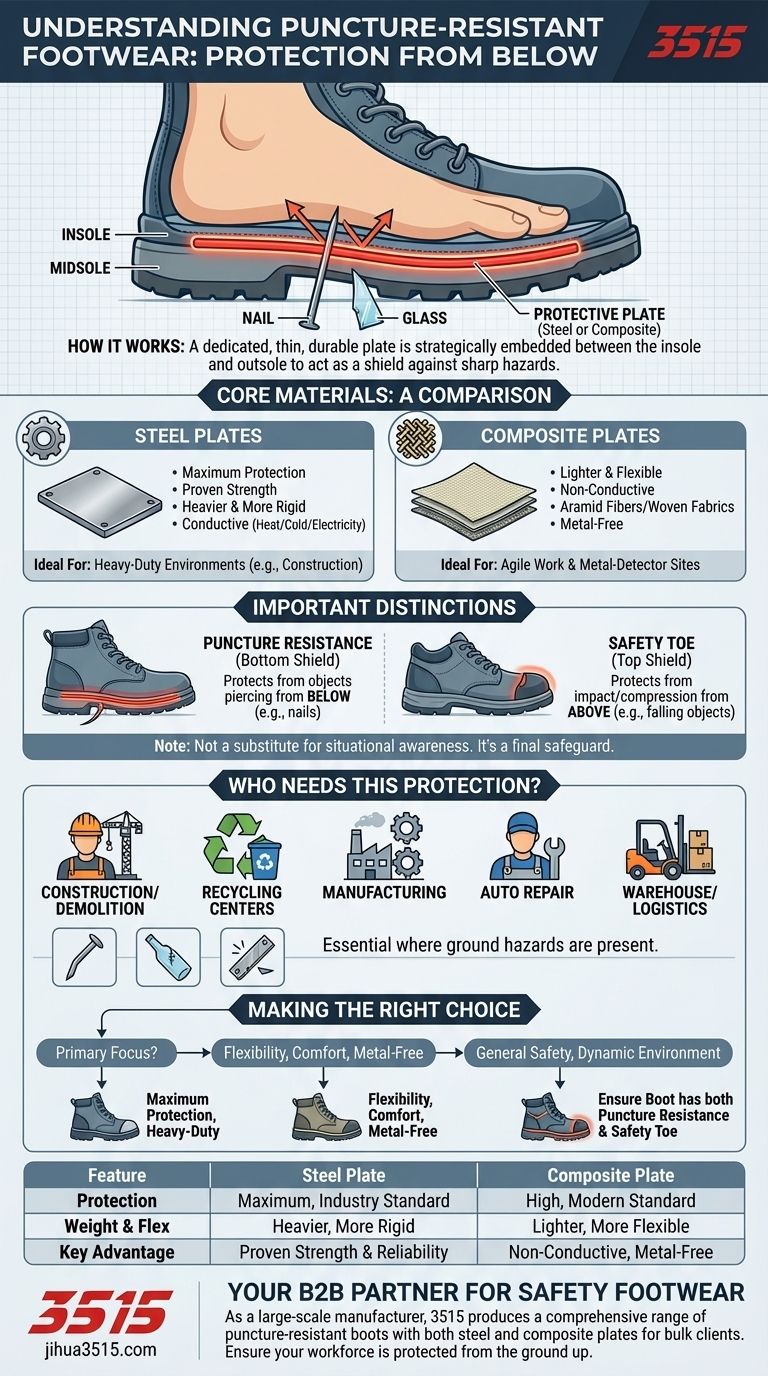

How Puncture Resistance Works

True puncture resistance is an engineered safety feature built directly into the footwear's construction. It relies on a specific internal component designed solely for this purpose.

The Protective Plate

The key element is a thin but incredibly durable plate. This plate is designed to be strong enough to stop the force of a sharp object, like a nail being stepped on with the full body weight of the wearer, from reaching the foot.

Strategic Placement in the Sole

This protective plate is strategically embedded within the boot's sole. It is typically positioned between the insole (the part your foot rests on) and the outsole (the part that contacts the ground), making it an integral part of the midsole assembly.

This placement ensures it protects the entire bottom surface of the foot without compromising the boot's external tread and grip.

The Core Materials: A Comparison

The material used for the protective plate impacts the boot's weight, flexibility, and suitability for certain environments. The choice is between traditional metal and modern non-metallic options.

Steel Plates

Steel is the classic material for puncture resistance. It offers exceptional protection against perforation and has been the industry standard for decades due to its proven strength and reliability.

Composite Plates

Modern composite plates are made from materials like Aramid fibers (such as Kevlar) or other durable woven fabrics. These non-metallic plates offer a key advantage in flexibility, making the boot more comfortable to walk in.

Woven Ballistic Fabrics

In some specialized applications, particularly military or jungle footwear, a layer of tightly woven ballistic fabric is used. This material provides flexible protection against sharp, pointed objects while being lightweight.

Understanding the Trade-offs

While essential for safety, the choice of puncture-resistant technology involves balancing protection with other factors. It's also crucial to understand its specific function.

Steel vs. Composite

Steel plates offer maximum protection but add weight and rigidity to the boot. They also conduct heat, cold, and electricity, making them unsuitable for certain work sites.

Composite plates are lighter, more flexible, and do not conduct electricity, making them ideal for workers who pass through metal detectors or require more agility. However, they may be a more premium option.

Distinguishing from Safety Toes

Puncture resistance is not the same as a safety toe. A puncture-resistant plate protects the bottom of the foot from threats from below. A safety toe cap (made of steel, composite, or alloy) protects the toes from impact and compression from above. While many safety boots have both, they are distinct features addressing different hazards.

Not a Substitute for Awareness

Puncture-resistant footwear is a critical piece of personal protective equipment (PPE), but it does not make a worker invincible. It is a final safeguard, not a replacement for situational awareness and avoiding visible hazards on the ground whenever possible.

Who Needs This Protection?

This type of footwear is essential for any occupation where the ground may conceal sharp objects. The risk is defined by the environment itself.

High-Risk Industries

Puncture-resistant boots are a requirement in numerous fields. Key industries include construction, demolition, recycling centers, manufacturing, auto repair, landscaping, and warehouse operations.

Common Environmental Hazards

The specific threats these boots protect against are ever-present in dynamic work sites. Workers are shielded from stray nails on a construction site, broken glass during renovations, or sharp metal scrap in a machine shop.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on the hazards of your specific environment and your daily physical demands.

- If your primary focus is maximum protection in a heavy-duty environment: Choose a boot with a traditional steel plate for proven, uncompromising resistance.

- If your primary focus is flexibility, comfort, and working in a metal-free zone: Opt for footwear with a non-metallic composite plate.

- If your primary focus is general safety in a dynamic environment: Ensure your boot is rated for puncture resistance, regardless of material, and also includes a safety toe for comprehensive protection.

Ultimately, specifying puncture-resistant footwear is a fundamental step in mitigating one of the most common and debilitating workplace injuries.

Summary Table:

| Feature | Steel Plate | Composite Plate |

|---|---|---|

| Protection Level | Maximum, Industry Standard | High, Modern Standard |

| Weight & Flexibility | Heavier, More Rigid | Lighter, More Flexible |

| Key Advantage | Proven Strength & Reliability | Non-Conductive, Metal-Free |

| Ideal For | Heavy-Duty Environments (e.g., Construction) | Metal-Detector Sites, Agile Work |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of puncture-resistant shoes and boots, engineered with both steel and composite plates to meet your specific safety and comfort requirements. Ensure your workforce is protected from the ground up—contact us today to discuss your needs and request a quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why is impact and puncture resistance a critical feature for fishing footwear? Protect Your Crew from Deck Hazards

- Why are NFPA fire boot standards important? Ensuring Life-Saving Protection for Firefighters

- How are metatarsal guards tested for impact protection? The Definitive Guide to ASTM F2413 Safety

- What are the different safety classes under EN ISO 20345? A Guide from SB to S5

- What materials are used in composite toe caps? Discover the lightweight, non-metallic alternatives

- How is human joint motion monitoring technology applied to the research and development of safety shoes? Design Insights

- What is the primary function of wireless pressure-sensing insoles? Enhance Industrial Safety with Real-Time Monitoring

- How do lace-up boots perform in terms of safety? Maximize Ankle Support and Mitigate Risks